A method for treating organic wastewater with a heterogeneous Fenton-coupled tubular membrane electrode

A technology of heterogeneous Fenton and organic wastewater, applied in the field of environmental engineering, can solve problems such as iron sludge solid waste, achieve the effects of reducing hazardous waste, good economy, and improving mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

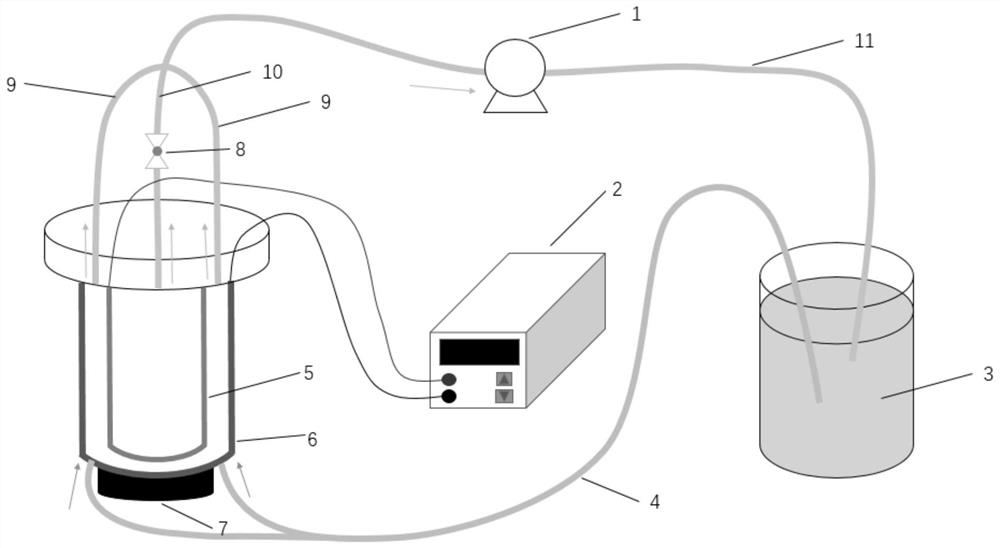

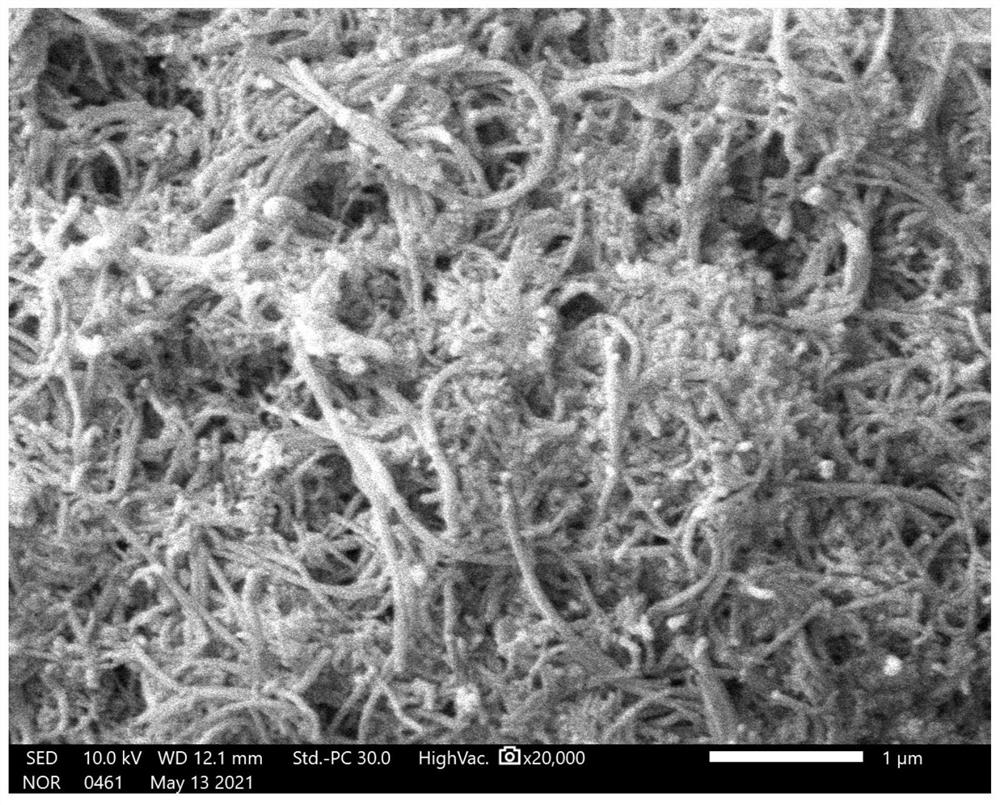

[0047] 1) adopt hydrothermal method, prepare Fe 3 o 4 @MWCNT heterogeneous Fenton catalyst

[0048] (1) Weigh 0.30g FeCl 3 ·6H 2 O in a 50mL beaker, add 10mL ultrapure water, stir until FeCl 3 ·6H 2 O is completely soluble in water.

[0049] (2) Add 20mL of 5mg·mL -1 Add the carboxylated multi-walled carbon nanotube dispersion liquid into the solution prepared in step (1), and stir for 30 minutes. (3) Slowly add 10 mL of diethanolamine into the solution prepared in step (2), and stir for 30 min.

[0050] (4) Add the precursor solution prepared in (3) into a 100 mL polytetrafluoroethylene-lined reactor and put it into a muffle furnace. Set the heating rate of the muffle furnace to 5°C min -1 , raised the temperature to 190°C and kept it warm for 6h, then cooled naturally to room temperature.

[0051] (5) Wash and filter the reaction product obtained in (4) with ultrapure water until the filtrate is neutral. Freeze-dry the obtained brown-black powder, and grind it thr...

Embodiment 2

[0069] 1) adopt coprecipitation method, prepare Fe 3 o 4 @PAC heterogeneous Fenton catalyst

[0070] (1) Weigh 2.0g FeCl respectively 2 4H 2 O and 5.4 g FeCl 3 ·6H 2 O, dissolved in 100mL ultrapure water.

[0071] (2) Add 5.0 g of powdered activated carbon (PAC) into the solution prepared in step (1), vacuumize and stir for 30 min.

[0072] (3) Put the solution prepared in step (2) into a 50°C water bath, slowly add NaOH solution to pH=9.0 under vigorous stirring, and age in a 50°C water bath for 12 hours.

[0073] (4) Wash and filter the reaction product obtained in (3) with ultrapure water until the filtrate is neutral. Dry the obtained black powder and grind it through a 200-mesh sieve to obtain Fe 3 o 4 @PAC heterogeneous Fenton catalyst, the carbon content is about 68%, and the BET specific surface area is 112.1223±0.5517m2 / g.

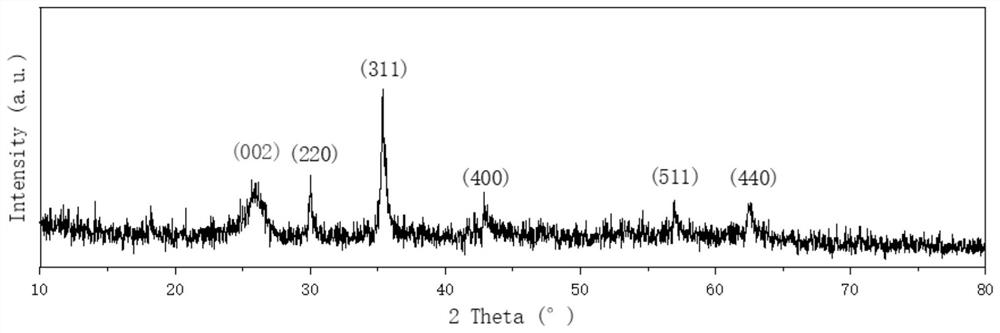

[0074] Such as Figure 7 Shown, for the Fe prepared in this example 3 o 4 XRD pattern of @PAC heterogeneous Fenton catalyst, (002) i...

Embodiment 3

[0082] 1) adopt coprecipitation method, prepare Fe 3 o 4 @PAC heterogeneous Fenton catalyst

[0083] With embodiment 2.

[0084] II) Preparation of Ti / PbO 2 Tubular Membrane Electrode and Reactor Design

[0085] With embodiment 1.

[0086] III) Degradation experiment

[0087] In the degradation experiment, 500mL 50mg / L pyrazole solution (containing 0.05mol / L Na 2 SO 4 As a supporting electrolyte, pH=4.0) was added into the tubular electrode reactor, the peristaltic pump was turned on for circulation, and the solution temperature was maintained at 30±1°C. Ti / PbO 2 The tubular membrane electrode is connected to the positive pole of the DC power supply, and the stainless steel cathode is connected to the negative pole of the DC power supply. Join Fe 3 o 4 @PAC heterogeneous Fenton catalyst and hydrogen peroxide, the catalyst and hydrogen peroxide concentrations are 1000mg / L and 200mg / L respectively, and the DC power supply is turned on at the same time to start the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com