A kind of continuous recovery device and continuous recovery process of glyphosate hydrolysis gas phase

A recovery device and glyphosate technology are applied in the field of glyphosate by-product recovery, which can solve the problems of hazardous waste of methyl chloride, consumption of methyl chloride, loss of by-products, etc., so as to avoid hazardous waste, improve recovery rate, and improve product yield. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

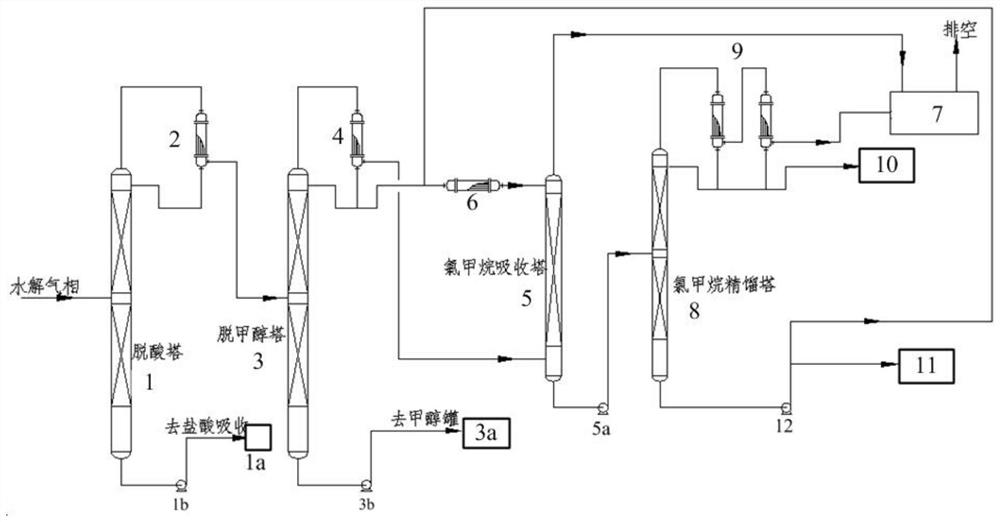

[0121] S1. The glyphosate hydrolysis gas enters the deacidification tower, the temperature at the top of the tower is 63°C, the temperature at the bottom of the tower is 102°C, and the temperature of the refrigerant in the first condensing device at the top of the tower is 28°C. Part of the gas components are discharged from the top of the deacidification tower. After condensation, the condensed methanol is completely refluxed, and the non-condensable gas enters the demethanol tower. The water and methanol in the hydrolysis gas form a self-reflux, and the hydrogen chloride and water flow to the bottom of the tower. Acid absorber for absorption.

[0122] Among them, the theoretical plate number of the deacidification tower is 18, and the gas inlet of the glyphosate hydrolysis gas is at the 10th plate.

[0123] S2. The non-condensable gas from the deacidification tower enters the methanol removal tower, the temperature at the top of the tower is 38°C, the temperature at the bott...

Embodiment 2

[0131] S1. The glyphosate hydrolysis gas enters the deacidification tower, the temperature at the top of the tower is 60°C, the temperature at the bottom of the tower is 100°C, and the temperature of the refrigerant in the first condensing device at the top of the tower is 30°C. Part of the gas components are discharged from the top of the deacidification tower. After condensation, the condensed methanol is completely refluxed, and the non-condensable gas enters the demethanol tower. The water and methanol in the hydrolysis gas form a self-reflux, and the hydrogen chloride and water flow to the bottom of the tower. Acid absorber for absorption.

[0132] Among them, the theoretical plate number of the deacidification tower is 18, and the gas inlet of the glyphosate hydrolysis gas is at the 12th plate.

[0133] S2. The non-condensable gas from the deacidification tower enters the methanol removal tower, the temperature at the top of the tower is 36°C, the temperature at the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com