Production method of low molecular weight polyether polyol

A low-molecular-weight polyether, production method technology, applied in ether preparation, alkylene oxide preparation ether, organic chemistry and other directions, can solve the problems of pollution, low product yield, etc., and achieve the effect of improving the ammoniation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

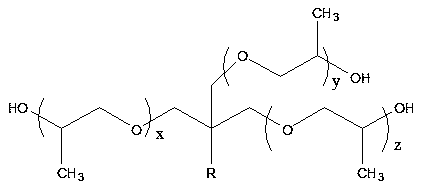

Image

Examples

Embodiment 1

[0023] (1) Polyether polyol synthesis:

[0024] Put 1000kg of propylene glycol and 30kg of catalyst polyetheramine D-230 into a clean external circulation reactor, and dehydrate at 80°C and -0.098MPa. Propylene oxide is then polymerized at a temperature of 130-140°C and a pressure of ≤0.2MPa. After the addition of 2026kg of propylene oxide is completed, it is aged for 1 hour and then cooled to below 60°C. A hydroxy polyether polyol.

[0025] (2) Application:

[0026] The polyether polyol containing 2 hydroxyl groups prepared in the above Example 1 (gas chromatography detection: content of dipropylene glycol 0.82%; content of tripropylene glycol and tetrapropylene glycol 89.52%, other components 9.66%) and liquid ammonia After spraying and mixing evenly, it is mixed with hydrogen, and then undergoes hydrogenation reaction in a fixed-bed reactor containing a skeleton nickel catalyst to obtain polyetheramine D-230. The amine value of polyetheramine D-230 was detected to be 8.3...

Embodiment 2

[0028] (1) Polyether polyol synthesis

[0029] Put 1000kg of propylene glycol and 450kg of catalyst polyetheramine D-230 into a clean external circulation reactor in sequence, dehydrate under the conditions of 80°C and -0.098MPa, when the moisture content is ≤0.05%, replace with nitrogen three times, and add propylene oxide continuously Polymerization is carried out at a temperature of 110-120°C and a pressure of ≤0.2MPa. After adding 2026kg of propylene oxide, after aging for 1 hour and then cooling down to below 60°C, the material is discharged to directly obtain a polyether polyol with a molecular weight of 230 and containing 2 hydroxyl groups. .

[0030] (2) Application

[0031] The polyether polyol containing 2 hydroxyl groups obtained in the above-mentioned Example 2 (gas chromatography detection: content of dipropylene glycol 0.91%; content of tripropylene glycol and tetrapropylene glycol 86.11%, other components 12.98%) and liquid ammonia After spraying and mixing ev...

Embodiment 3

[0033] (1) Synthesis of 3 hydroxyl polyether polyols

[0034] Put 642kg of glycerol and 150kg of catalyst polyetheramine T-403 into a clean external circulation reactor in turn, dehydrate under the conditions of 80°C and -0.098MPa, when the moisture content is ≤0.05%, replace with nitrogen three times, and continuously add epoxy Propane is polymerized at a temperature of 120-130°C and a pressure of ≤0.2MPa. After adding 2358kg of propylene oxide, after aging for 1 hour and then cooling down to below 60°C, the material is discharged to directly obtain a polyether polyether compound with a molecular weight of 430 and containing 3 hydroxyl groups. alcohol.

[0035] (2) Application

[0036] The polyether polyol containing 3 hydroxyls and liquid ammonia prepared in the above example 3 are uniformly mixed by spraying and then mixed with hydrogen, and then hydrogenation reaction occurs in a fixed-bed reactor containing a skeleton nickel catalyst to obtain polyetheramine T-403. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com