Anti-blue-ray resin composition and preparation method thereof

A resin composition and anti-blue light technology, which is applied in the field of anti-blue light resin composition and its preparation, can solve the problem of not being able to greatly reduce the harm of blue light to eyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

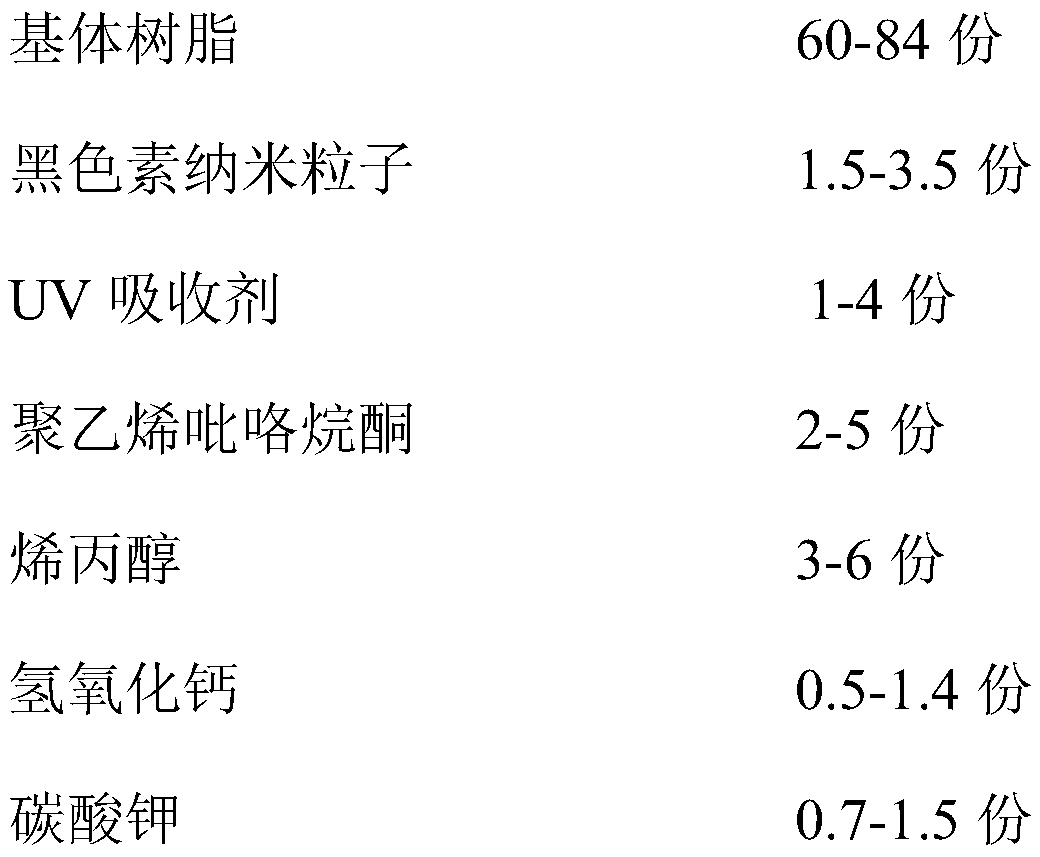

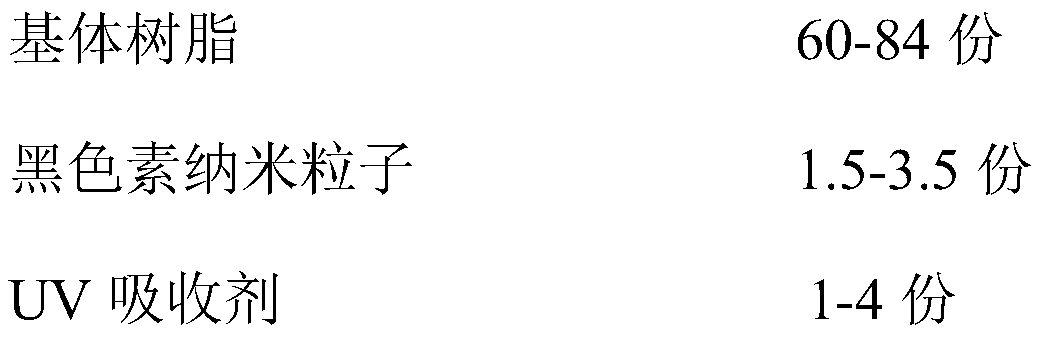

[0022] An anti-blue light resin composition, comprising by weight:

[0023]

[0024] A kind of preparation method of anti-blue light resin composition, carry out according to the following steps:

[0025] (1) Diallyl terephthalate, diallyl isophthalate, dibutyltin oxide, allyl alcohol, calcium hydroxide, potassium carbonate and heat stabilizer CAS 3287-06-7 are mixed according to 80 The mass ratio of :82:0.1:28:1.1:1.2:0.08 is put into the reactor, heated to 140°C, reacted for 18h under stirring conditions, and then cooled to room temperature;

[0026] (2) the material after reaction in step (1), dipropylene maleate and thermostabilizer are dropped in the reactor by the mass ratio of 92:8:0.06, react 5h under stirring condition, obtain matrix resin;

[0027] (3) Add NaOH to the acid solution of 3,4-dihydroxyphenylalanine, adjust the pH to 8, add potassium permanganate, and polymerize 3,4-dihydroxyphenylalanine at 100°C , the reaction time was 8h to obtain melanin nanopart...

Embodiment 2

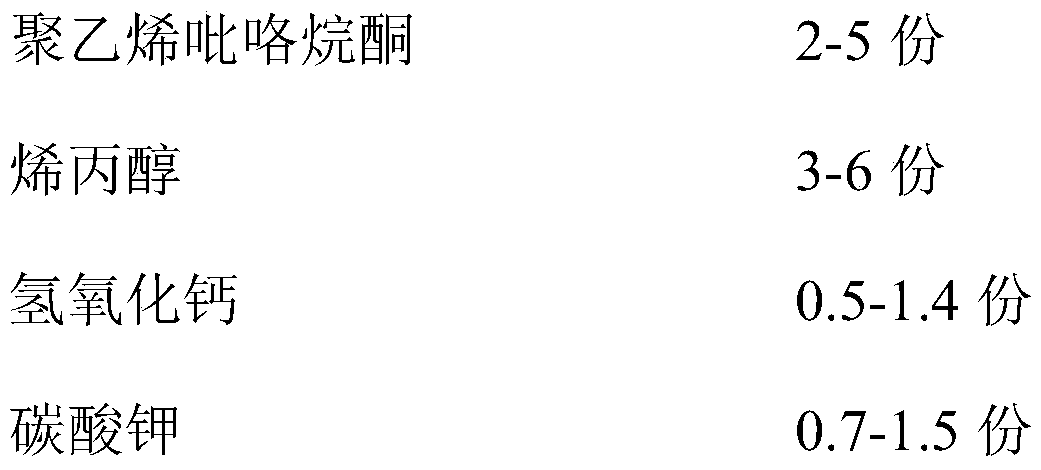

[0032] An anti-blue light resin composition, comprising by weight:

[0033]

[0034]

[0035] A kind of preparation method of anti-blue light resin composition, carry out according to the following steps:

[0036] (1) Diallyl terephthalate, diallyl isophthalate, dibutyltin oxide, allyl alcohol, calcium hydroxide, potassium carbonate and heat stabilizer CAS 26544-22-9 are mixed according to 85 The mass ratio of :80:0.2:28:0.8:1.3:0.07 is put into the reactor, heated to 135°C, reacted for 20h under stirring conditions, and then cooled to room temperature;

[0037] (2) the material after reaction in step (1), dipropylene maleate and thermostabilizer are dropped in the reactor by the mass ratio of 95:10:0.1, react 6h under stirring condition, obtain matrix resin;

[0038] (3) Add NaOH to the acid solution of 3,4-dihydroxyphenylalanine, adjust the pH to 9, add potassium permanganate, and polymerize 3,4-dihydroxyphenylalanine at 120°C , the reaction time is 10h to obtain mel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com