Laying hen feed and preparation method thereof

A technology for laying hen feed and raw materials, applied in the field of animal feed, can solve the problems of insufficient production performance, high production cost and transportation cost, and small range of regulating nutrient concentration, so as to improve the utilization rate of feed, good physique, palatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

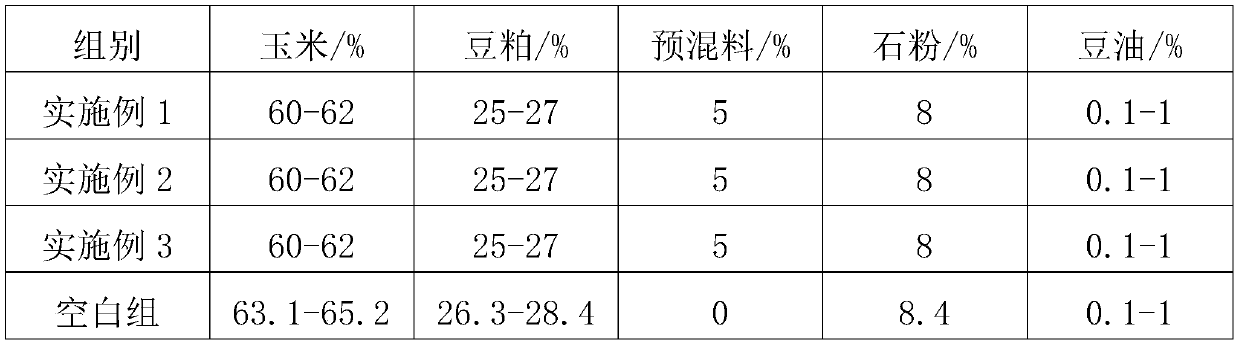

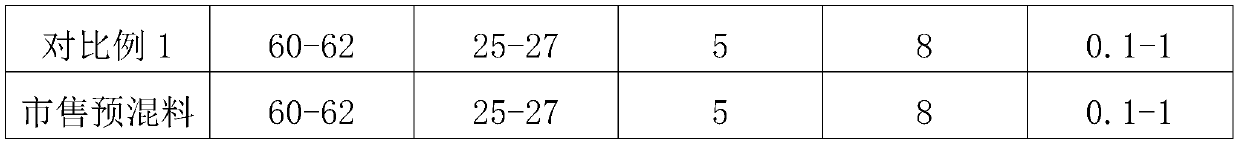

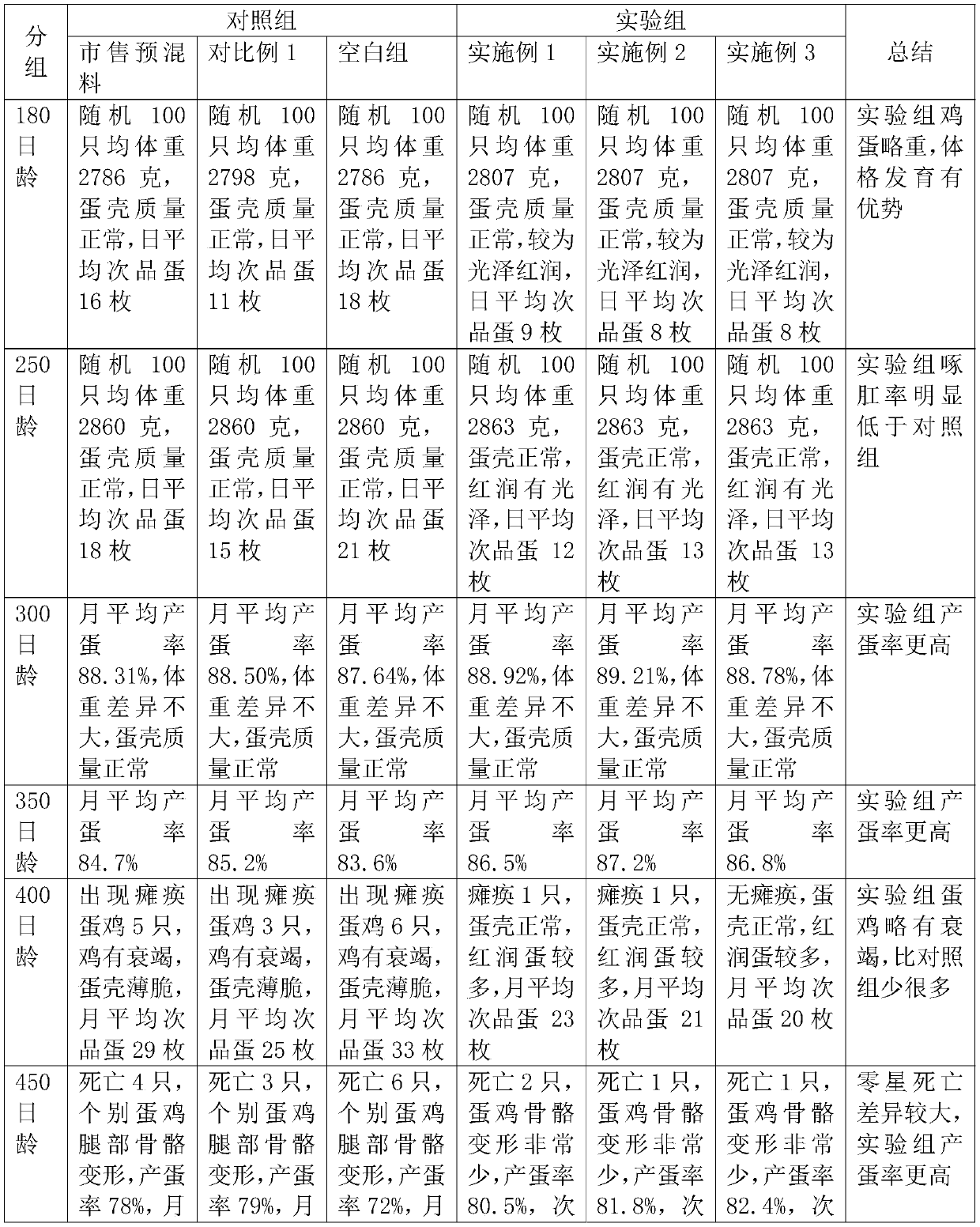

Method used

Image

Examples

Embodiment 1

[0035] The present embodiment provides a feed for laying hens, which comprises the following raw materials: methionine 2kg, lysine 1.5kg, multidimensional 0.3kg, feeding sodium chloride 3kg, sodium bicarbonate 1kg, monocalcium phosphate 12kg, Vitamin E 0.05kg, antioxidant 0.14kg, compound trace elements 1.5kg, phytase 0.3kg, Bacillus subtilis 0.03kg, rice bran 2.03kg, choline chloride 1.0kg, calcium formate 1.5kg, calcium lactate 0.3kg and Ding Calcium acid 0.7kg.

[0036]The composite trace element comprises by weight percentage: 1.6% of methionine, 20% of iron glycinate, 16.1% of manganese methionine, 13% of zinc methionine, 0.06% of sodium selenite, 0.08% of calcium iodate, and the rest is stone powder carrier.

[0037] Described multivitamin comprises by weight percentage: vitamin A accounts for 5.5% of described multivitamin gross weight, vitamin D3 accounts for 2% of described multivitamin gross weight, and vitamin E accounts for 20% of described multivitamin gross weigh...

Embodiment 2

[0042] The present embodiment provides a feed for laying hens, which comprises the following raw materials: 1 kg of methionine, 0.5 kg of lysine, 0.5 kg of multidimensional, 2 kg of sodium chloride for feeding, 3 kg of sodium bicarbonate, 8 kg of monocalcium phosphate, Vitamin E 0.15kg, antioxidant 0.10kg, compound trace elements 2.5kg, phytase 0.2kg, Bacillus subtilis 0.07kg, rice bran 1.63kg, choline chloride 1.5kg, calcium formate 0.5kg, calcium lactate 0.7kg and Ding Calcium acid 0.3kg.

[0043] The composite trace element comprises by weight percentage: 1.6% of methionine, 20% of iron glycinate, 16.1% of manganese methionine, 13% of zinc methionine, 0.06% of sodium selenite, 0.08% of calcium iodate, and the rest is stone powder carrier.

[0044] Described multivitamin comprises by weight percentage: vitamin A accounts for 5.5% of described multivitamin gross weight, vitamin D3 accounts for 2% of described multivitamin gross weight, and vitamin E accounts for 20% of descri...

Embodiment 3

[0049] The present embodiment provides a feed for laying hens, which comprises the following raw materials: 1.5kg methionine, 1kg lysine, 0.4kg multivitamin, 2.5kg sodium chloride for feeding, 2kg sodium bicarbonate, monocalcium phosphate 10kg, vitamin E 0.1kg, antioxidant 0.12kg, compound trace elements 2kg, phytase 0.25kg, Bacillus subtilis 0.05kg, rice bran 1.83kg, choline chloride 1.25kg, calcium formate 1kg, calcium lactate 0.5kg and Ding Calcium acid 0.5kg; Described antioxidant is tert-butyl hydroxyanisole. Tert-butyl hydroxyanisole has strong antibacterial ability and antioxidant ability.

[0050] The composite trace element comprises by weight percentage: 1.6% of methionine, 20% of iron glycinate, 16.1% of manganese methionine, 13% of zinc methionine, 0.06% of sodium selenite, 0.08% of calcium iodate, and the rest is stone powder carrier.

[0051] Described multivitamin comprises by weight percentage: vitamin A accounts for 5.5% of described multivitamin gross weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com