Electromagnetic controlled-release microcapsule/steel fiber self-repairing concrete and preparation method thereof

A technology of microcapsules and steel fibers, which is applied in the field of concrete, can solve the problems of limiting the effect of microcapsules on concrete damage and micro-crack repair, low magnetic iron powder content, and restrictions on practical application, so as to improve the repair effect, improve thermal conductivity, The effect of accelerating melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] An electromagnetic controlled release microcapsule / steel fiber self-repairing concrete is prepared as follows:

[0032] (1) Take by weighing 100 parts of PO42.5 ordinary portland cement, 0 parts of fly ash, 180 parts of river sand, 320 parts of coarse aggregate, 3 parts of electromagnetic controlled release microcapsules, 22.5 parts of surface-treated steel fibers, 0.7 parts of polycarboxylate superplasticizer, and 32 parts of water;

[0033] (2) Add the weighed cement, fly ash, fine aggregate, coarse aggregate, electromagnetic controlled release microcapsules, and surface-treated steel fibers into the concrete mixer and stir for 2 minutes, then add water and water reducer, and continue stirring for 3 minutes to make it evenly mixed, and the electromagnetic controlled-release microcapsule / steel fiber self-healing concrete is prepared.

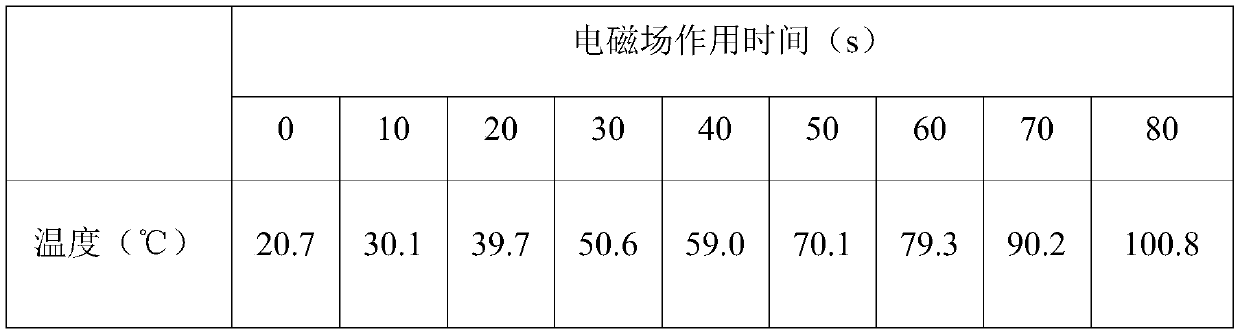

[0034] The electromagnetic controlled-release microcapsules / steel fiber self-repairing concrete prepared in this example was poured in...

Embodiment 2

[0049] An electromagnetic controlled release microcapsule / steel fiber self-repairing concrete is prepared as follows:

[0050] (1) Weigh 100 parts of PO42.5 ordinary Portland cement, 10 parts of fly ash, 160 parts of river sand, 330 parts of coarse aggregate, 4 parts of electromagnetic controlled release microcapsules, Surface-treated steel fiber 30 parts, polycarboxylate superplasticizer 0.8 parts, water 33 parts;

[0051] (2) Add the weighed cement, fly ash, fine aggregate, coarse aggregate, electromagnetic controlled release microcapsules, and surface-treated steel fibers into the concrete mixer and stir for 2 minutes, then add water and water reducer, and continue stirring for 3 minutes to make it evenly mixed, and the electromagnetic controlled-release microcapsule / steel fiber self-healing concrete is prepared.

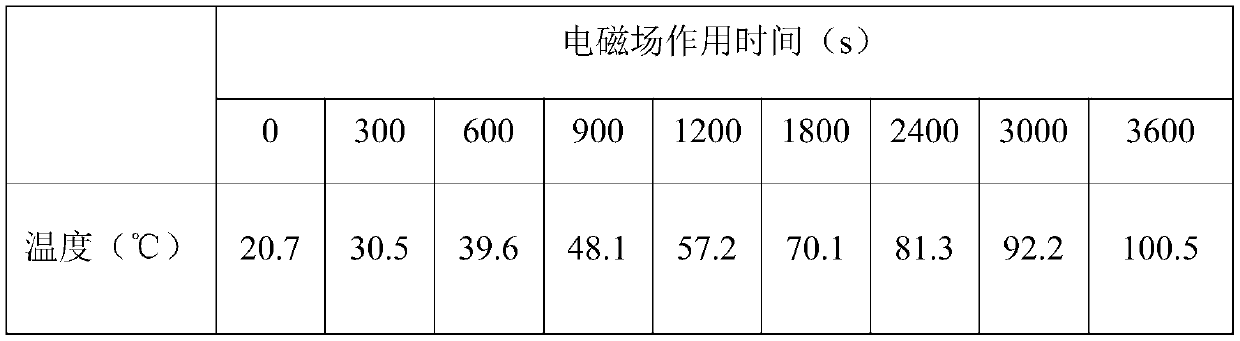

[0052] The electromagnetic controlled-release microcapsules / steel fiber self-repairing concrete prepared in this example was poured into a mold of 100mm×100mm×1...

Embodiment 3

[0057] An electromagnetic controlled release microcapsule / steel fiber self-repairing concrete is prepared as follows:

[0058] (1) Weigh 100 parts of PO52.5 ordinary portland cement, 20 parts of fly ash, 200 parts of river sand, 350 parts of coarse aggregate, 5 parts of electromagnetic controlled release microcapsules, Surface-treated steel fiber 37.5 parts, polycarboxylate superplasticizer 1.0 part, water 35 parts;

[0059] (2) Add the weighed cement, fly ash, fine aggregate, coarse aggregate, electromagnetic controlled release microcapsules, and surface-treated steel fibers into the concrete mixer and stir for 2 minutes, then add water and water reducer, and continue stirring for 3 minutes to make it evenly mixed, and the electromagnetic controlled-release microcapsule / steel fiber self-healing concrete is prepared.

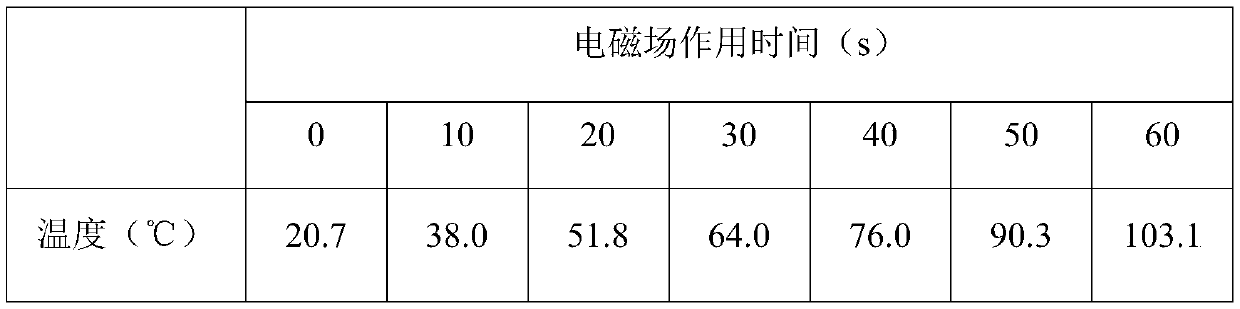

[0060] The electromagnetic controlled-release microcapsules / steel fiber self-repairing concrete prepared in this example was poured into a mold of 100mm×100mm×...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com