Method and device for generating element steam through spontaneous induction of micro-droplets

A vapor generation and micro-droplet technology, applied in the field of analytical chemical atomic spectroscopy, can solve the problems of affecting the anti-interference effect of the element to be tested, affecting the accurate determination of the element, and increasing the complexity of the device, so as to reduce the test cost, the structure is simple, and the Effects of Reagent Interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

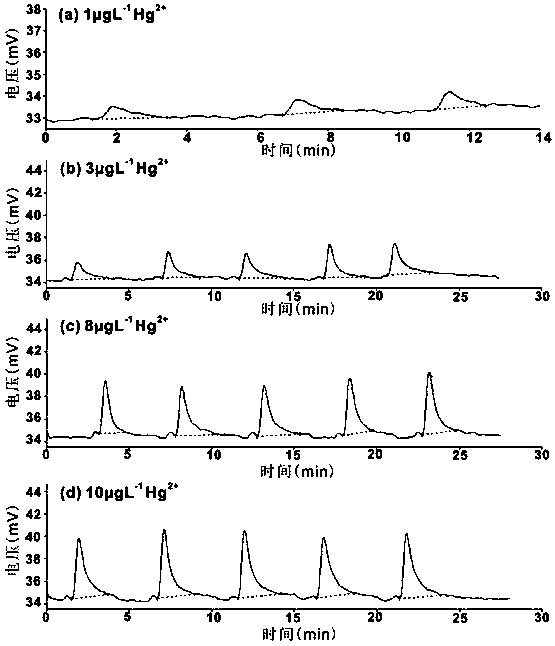

[0036] Such as figure 1 For the device and process shown, a glass concentric pneumatic nebulizer is selected, the inner diameter of the central tube of the nebulizer is 0.1 mm, the Ar carrier gas pressure is 40 psi, and the pure water flow rate is 100 µL min -1 , with a flow injection loop volume of 100 µL. 1-10 µgL -1 Hg 2+ The standard solution is spontaneously reduced to volatile Hg by micro-droplets 0 , after the cold atomic fluorescence detection, the peak figure is as follows figure 2 Shown in a-d, illustrate that the method of the present invention can be used for Hg 2+ of steam is generated. at 1-10 µg L -1 Hg in range 2+ The peak area signal value and its concentration also showed a good linear relationship (R 2 =0.9997), such as image 3 Shown, illustrating that the method of the present invention can also be used for Hg 2+ quantitative analysis.

Embodiment 2

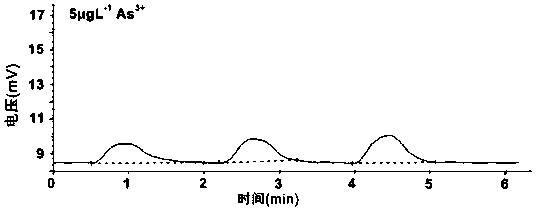

[0038] Such asfigure 1 For the device and process shown, a glass concentric pneumatic nebulizer is selected, the inner diameter of the central tube of the nebulizer is 0.2 mm, the nebulizing gas pressure is 50 psi, and the flow rate of pure water is 100 µL min -1 , with a flow injection loop volume of 100 µL. 5 μg L -1 As 3+ Vapor generation and atomization to As under the action of hydrogen radicals in micro-droplets 0 , after the cold atomic fluorescence detection, the peak figure is as follows Figure 4 , indicating that the microdroplet spontaneous vapor generation process can also be used for As 3+ determination.

Embodiment 3

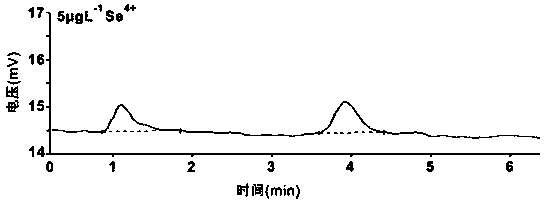

[0040] Such as figure 1 For the device and process shown, a quartz concentric pneumatic nebulizer is selected, the inner diameter of the central tube of the nebulizer is 0.2 mm, the nebulizing gas pressure is 50 psi, and the flow rate of pure water is 100 µL min -1 , with a flow injection loop volume of 100 µL. 5 μg L -1 Se 4+ Vapor generation and atomization to Se are achieved under the action of hydrogen radicals in micro-droplets 0 , after the cold atomic fluorescence detection, the peak figure is as follows Figure 5 , indicating that the microdroplet spontaneous vapor generation process can also be used for Se 4+ determination.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com