Neodymium sesquioxide doped carbon nitride photocatalyst and preparation method thereof

A light technology of neodymium trioxide and carbon nitride, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of harsh synthesis conditions, inefficient solar energy utilization, and cumbersome synthesis steps, and achieve Mild reaction conditions, less reagent pollution, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

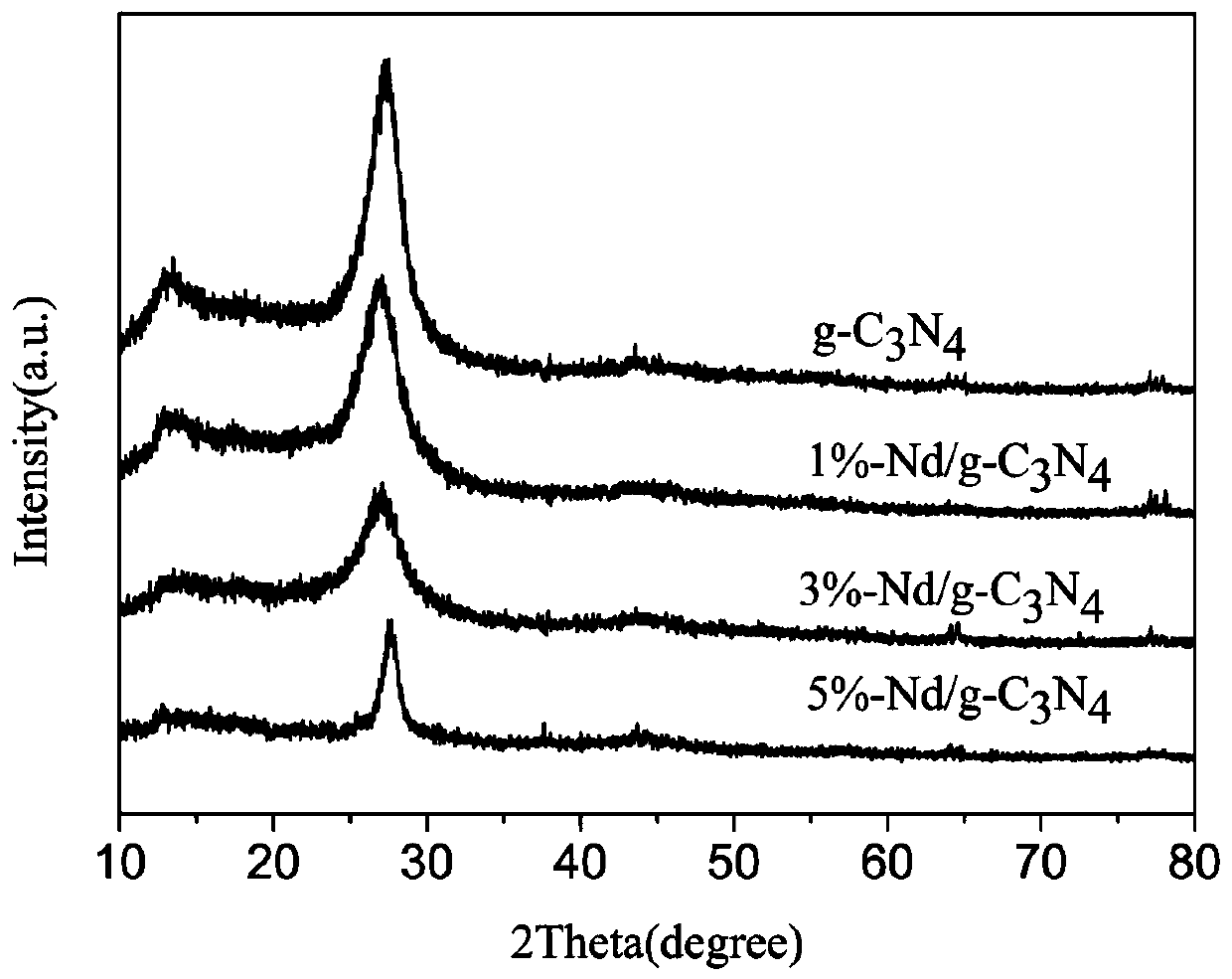

[0026] Graphite carbon nitride (g-C 3 N 4 ): Put 10g of urea in a 30ml crucible, in a muffle furnace at a heating rate of 5°C / min, and keep at 550°C for 3h to obtain graphitic carbon nitride (g-C 3 N 4 ).

Embodiment 2

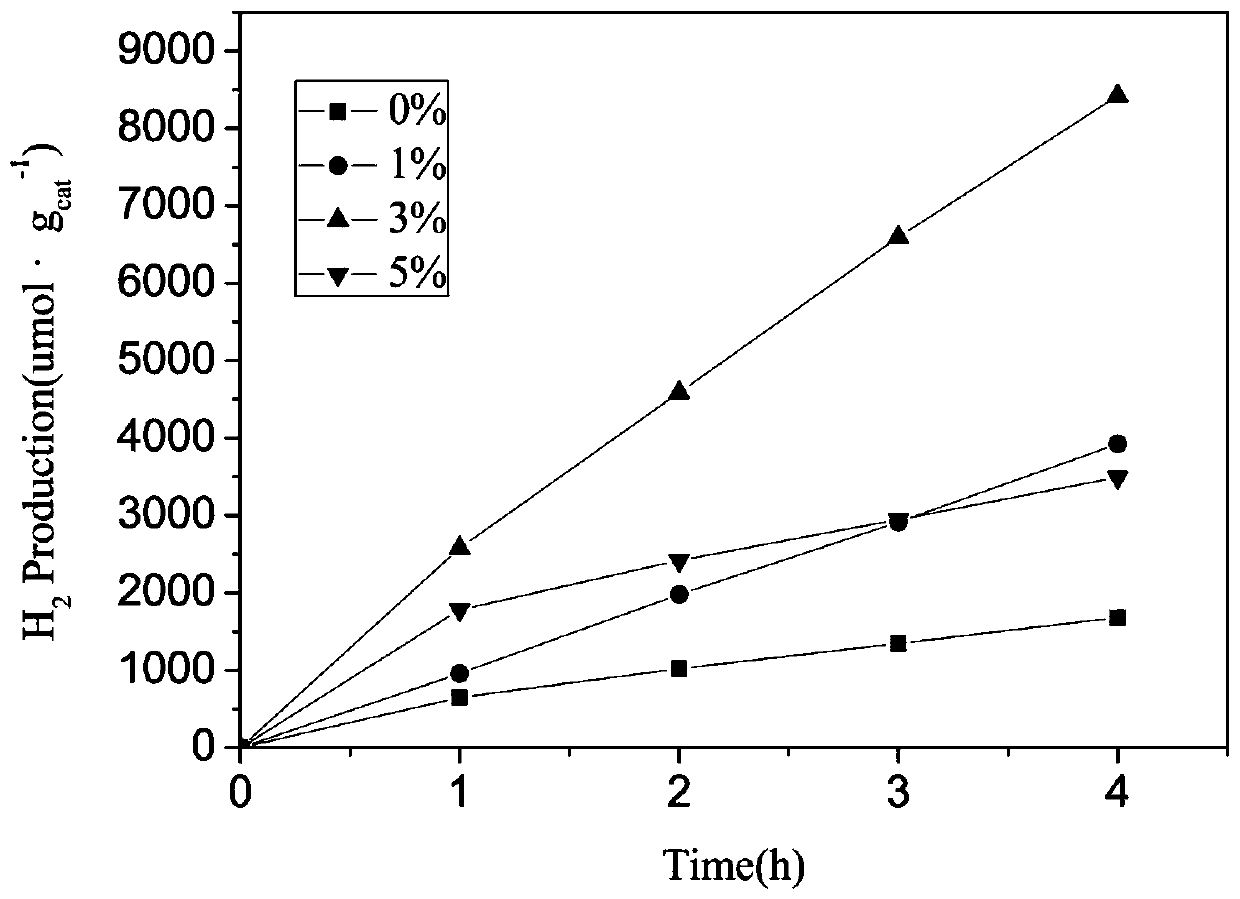

[0028] Graphite carbon nitride (g-C 3 N 4 ): Put 10g of urea in a 30ml crucible, in a muffle furnace at a heating rate of 5°C / min, and keep at 550°C for 3h to obtain graphitic carbon nitride (g-C 3 N 4 ); 0.0122g of Nd(NO 3 ) 3 ∙6H 2 O was dissolved in 20ml of deionized water, followed by the addition of 5g of g-C 3 N 4 , sealed and stirred in a water bath at 70°C for 6h; let the mixed solution come into contact with air, and evaporate to dryness under stirring in a water bath at 70°C to obtain a solid powder; keep the solid powder at 550°C under nitrogen protection for 4h, at a rate of 5°C / min heating rate, to obtain the product: neodymium trioxide doped carbon nitride (Nd 2 o 3 / g -C 3 N 4). The generated product is according to the reactant raw material Nd: g-C 3 N 4 The amount was prepared at a ratio of 1:100.

Embodiment 3

[0030] Graphite carbon nitride (g-C 3 N 4 ): Put 10g of urea in a 30ml crucible, in a muffle furnace at a heating rate of 5°C / min, and keep at 550°C for 3h to obtain graphitic carbon nitride (g-C 3 N 4 ); 0.0365g of Nd(NO 3 ) 3 ∙6H 2 O was dissolved in 20ml of deionized water, followed by the addition of 5g of g-C 3 N 4 , sealed and stirred in a water bath at 70°C for 6h; let the mixed solution come into contact with air, and evaporate to dryness under stirring in a water bath at 70°C to obtain a solid powder; keep the solid powder at 550°C under nitrogen protection for 4h, at a rate of 5°C / min heating rate, to obtain the product: neodymium trioxide doped carbon nitride (Nd 2 o 3 / g -C 3 N 4 ). The generated product is according to the reactant raw material Nd: g-C 3 N 4 The amount was prepared at a ratio of 3:100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com