Preparation method of sulfasalazine impurity D

A technology for sulfasalazine and impurities, which is applied in the field of drug impurity synthesis, can solve the problems of difficult removal and easy residues, and achieves the effects of convenient purification, high reaction efficiency and great application research value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

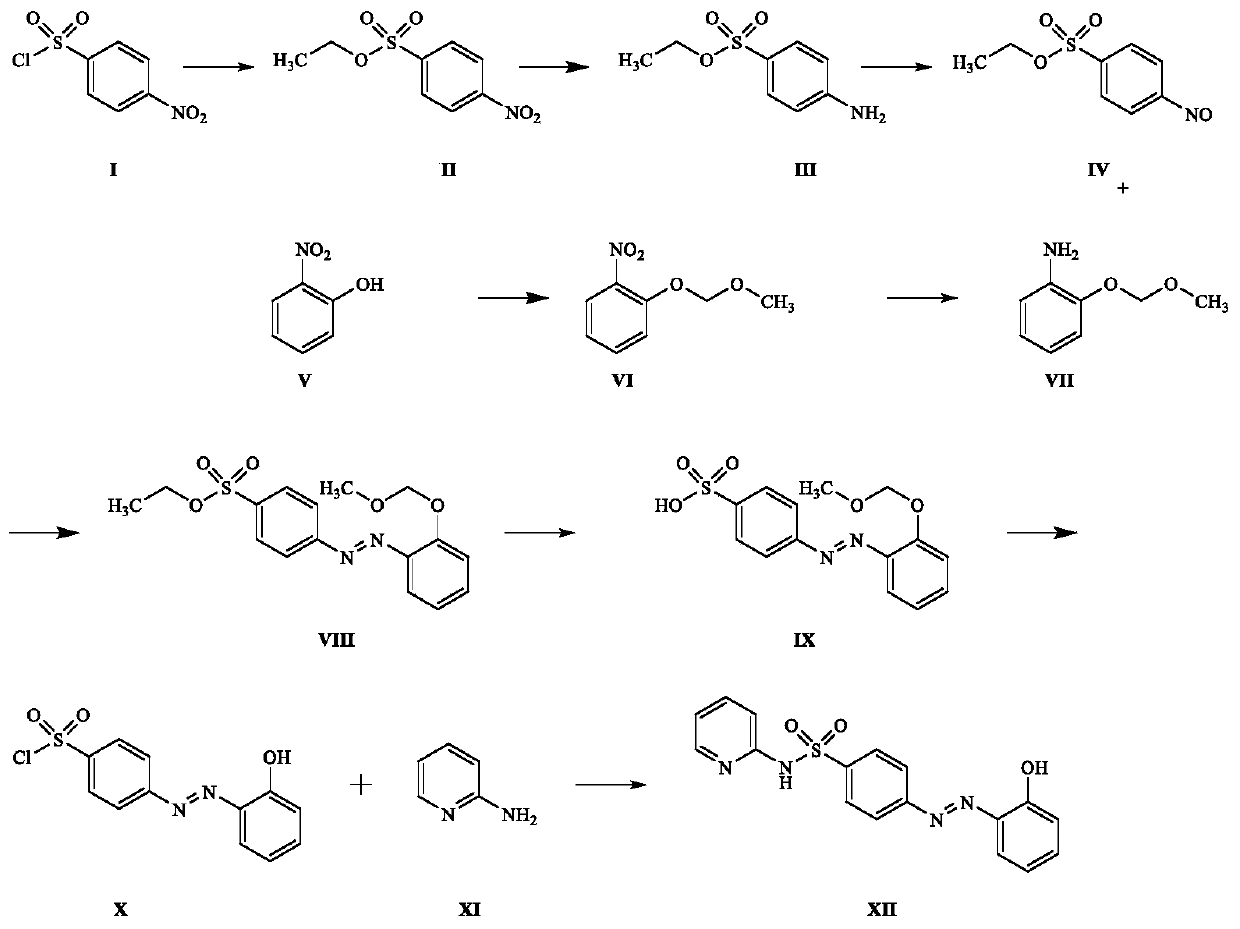

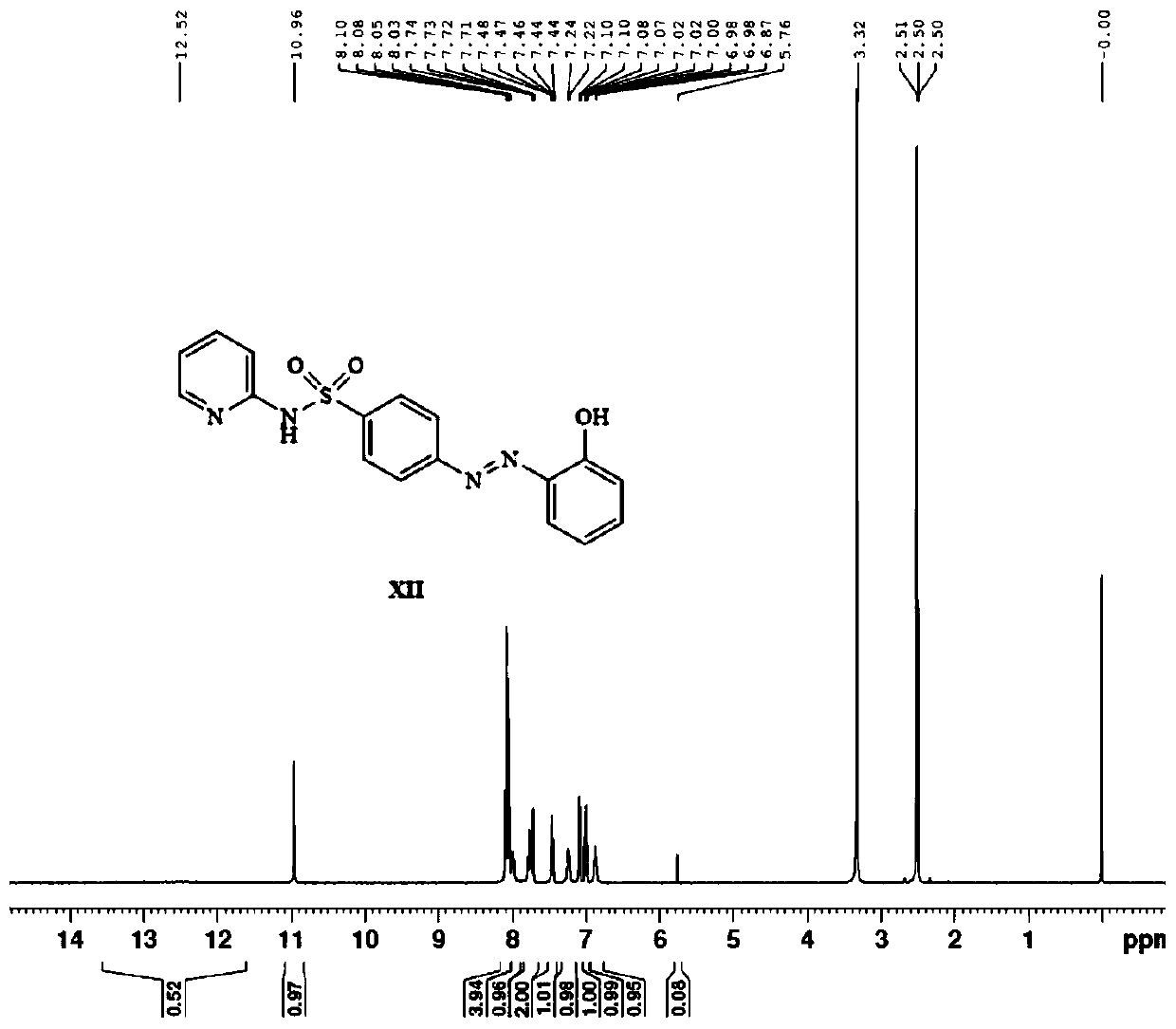

[0041] Such as figure 1 Shown, a kind of preparation method of sulfasalazine impurity D, comprises the following steps:

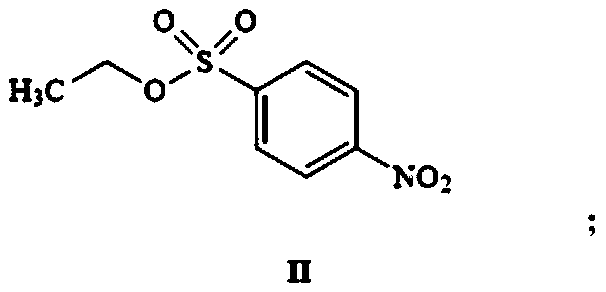

[0042] (1) Dissolve 100.0 g of p-nitrobenzenesulfonyl chloride in 6 L of dioxane, add 110.5 g of sodium ethoxide (prepared from metal sodium and absolute ethanol) at 40° C. and react overnight. TLC spotting shows that the raw materials are completely reacted. Treatment: Add 1L of water and 500mL of ethyl acetate to extract to obtain intermediate II (92.4g, 88%) as a yellow solid;

[0043] (2) Dissolve 50.0g of intermediate II in 500mL of ethanol, add 15.0g of Rey-Ni hydrogenation balloon at room temperature and react overnight, TLC spot plate shows that the reaction of the raw materials is complete, filter the reacted mixture with suction, and spin the filtrate to obtain a yellow solid Intermediate III (42.0 g, 96%);

[0044] (3) Dissolve 20.0g of intermediate III in 500mL of dichloromethane, add 61.1g of mCPBA, and react at 25°C for 2h. TLC spotting shows ...

Embodiment 2

[0052] Such as figure 1 Shown, a kind of preparation method of sulfasalazine impurity D, comprises the following steps:

[0053] (1) Dissolve 100g of p-nitrobenzenesulfonyl chloride in 3L of THF, add 153.5g of sodium ethoxide (prepared from metal sodium and absolute ethanol), and react overnight at 60°C. TLC spotting shows that the raw materials have reacted completely, and add 1L of water , 500mL of ethyl acetate was extracted to obtain 100.8g of yellow solid intermediate II, with a yield of 96%;

[0054] (2) Dissolve 50.0g of intermediate II in 1L of ethanol, add 10.0g of palladium-calcium carbonate, and react overnight with a hydrogenation balloon at room temperature. TLC spotting shows that the reaction of the raw materials is complete. The reaction mixture is suction filtered, and the filtrate is spin-dried to obtain a yellow solid intermediate III (43.1 g, 99%);

[0055] (3) Dissolve 20.0g of intermediate III in 500mL of dichloromethane, add 70.5g of peracetic acid, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com