Botanical antibacterial microcapsule emulsion and preparation method thereof

A plant source and microcapsule technology, which is applied in botany equipment and methods, plant growth regulators, chemicals for biological control, etc., can solve the problems of poor stability of plant source antibacterial agents, improve the binding force, improve The effect of antimicrobial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

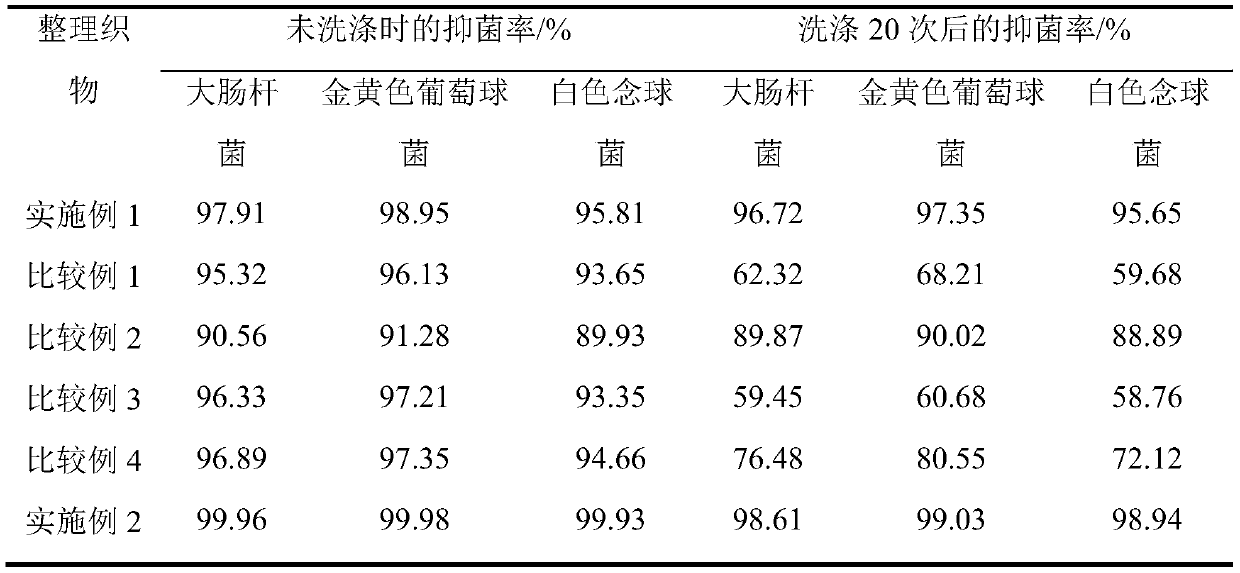

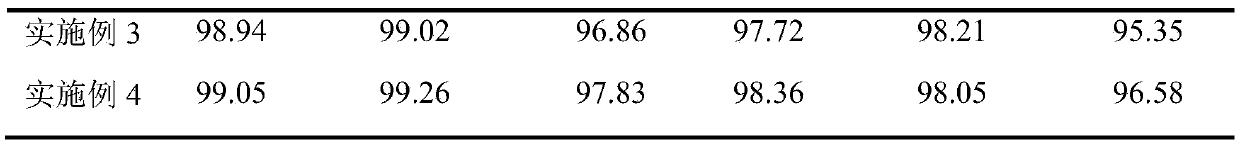

Embodiment 1

[0025] (1) Add 0.3g of methacryloyloxyethyl dodecyl dimethyl ammonium bromide, 0.15g of non-ionic surfactant Pingping plus O-30 and deionized water in a four-necked flask to prepare a mass fraction of 0.5 % surfactant solution, add 0.9g each of Artemisia argyi essential oil, forsythia essential oil, and rhododendron essential oil, and emulsify at a speed of 1500r / min at 20°C for 2h to obtain a plant-derived antibacterial agent emulsion;

[0026] (2) After dissolving 0.5g cetyltrimethylammonium bromide and 0.5g Pingpingjia O-30 in 68mL deionized water, add 20.0g soft monomer butyl acrylate and 5.0g hard monomer methyl Methyl acrylate, 3g functional monomer γ-(methacrylamide) propyltrimethylammonium chloride, 2g modified monomer β-hydroxypropyl methacrylate, 1g crosslinking monomer glycidyl acrylate, at stirring speed Under the condition of 1500r / min, emulsify for 45min to prepare monomer pre-emulsion;

[0027] (3) Dissolve 0.2g sodium persulfate and 0.1g sodium bisulfite in 15...

Embodiment 2

[0048] (1) Add 0.75g methacryloyloxyethyl octadecyldimethyl ammonium bromide, 0.25g Pingpingjia O-30 and deionized water in a four-necked flask to prepare a surfactant with a mass fraction of 1%. Solution, add 4g mugwort essential oil, 12g forsythia essential oil, 4g rhododendron essential oil, and emulsify at 3000r / min at 40°C for 1 hour to obtain a botanical antibacterial agent emulsion;

[0049] (2) After dissolving 2.4g cetyltrimethylammonium chloride and 0.6g Pingpingjia O-30 in 45mL deionized water, add 30.0g soft monomer ethyl acrylate and 10.0g hard monomer methyl Ethyl acrylate, 5g functional monomer methacryloxyethyltrimethylammonium chloride, 4g modified monomer β-hydroxyethyl methacrylate, 3g crosslinking monomer glycidyl methacrylate, stirring Under the condition of rotating speed 3000r / min, emulsify for 30min to prepare monomer pre-emulsion;

[0050] (3) Dissolve 0.75g sodium persulfate and 0.25g sodium bisulfite in 15mL deionized water to prepare initiator solu...

Embodiment 3

[0053] (1) Add 0.5g methacryloyloxyethylhexadecyldimethylammonium bromide, 0.2g Pingpingjia O-30 and deionized water into a four-necked flask to prepare a 0.8% surfactant solution , add 1.4g mugwort essential oil, 2.8g forsythia essential oil, 1.4g rhododendron essential oil, and emulsify at 30°C for 1.5h at a speed of 2000r / min to obtain a botanical antibacterial agent emulsion;

[0054] (2) Dissolve 4g of dodecyltrimethylammonium bromide and 2g of Pingpingjia O-30 in 54mL of deionized water, then add 24.0g of soft monomer octyl acrylate and 7.5g of hard monomer methyl methacrylate Ester, 3.5g functional monomer methacryloxyethyl dimethyl benzyl ammonium chloride, 3g modified monomer β-hydroxypropyl methacrylate, 2.0g crosslinking monomer glycidyl acrylate, stirring Under the condition of rotating speed 2000r / min, emulsify for 35min to prepare monomer pre-emulsion;

[0055] (3) 0.2g sodium persulfate and 0.08g sodium bisulfite were dissolved in 15mL deionized water to prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com