Temperature-sensitive material, bactericide and its preparation method and application

A temperature-sensitive material and bactericide technology, applied in the field of materials, can solve problems such as easy burst release of copper ions, and achieve the effects of improving the efficacy period, simple preparation method, and improving the bactericidal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

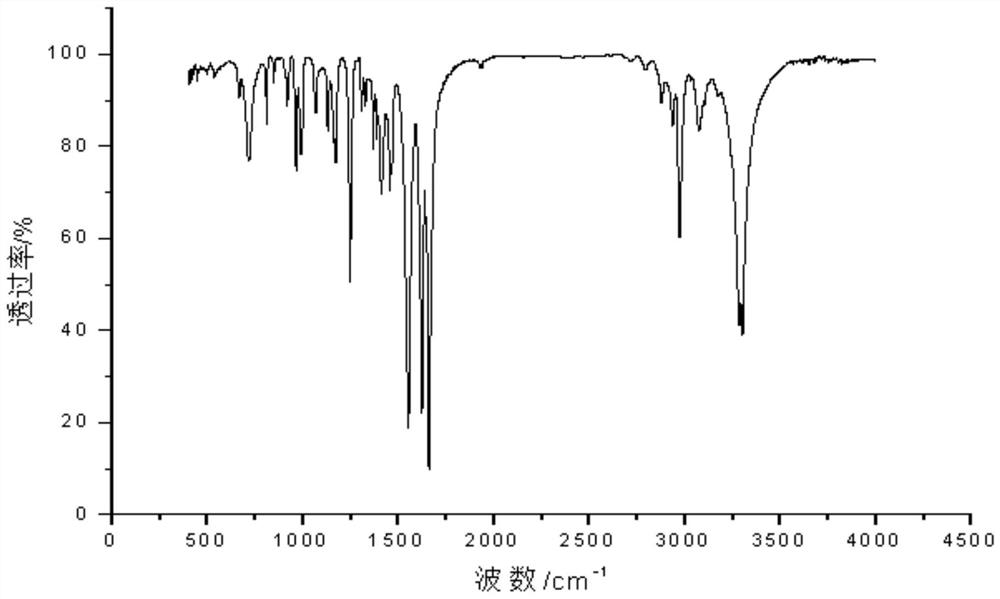

[0050] A temperature-sensitive material, the specific preparation method is as follows:

[0051] 1) Place a 250mL three-necked flask containing 60mL of distilled water in a water bath, raise the temperature of the water bath to 40°C, and accurately weigh 0.50g of N-isopropylacrylamide and 0.017g of N,N-methylenebispropene Amide, 0.01g methacryloyloxyethyltrimethylammonium chloride and 0.013g sodium lauryl sulfate were added to a 250mL three-necked flask, nitrogen was bubbled, and mechanical stirring was carried out at a speed of 3500 rpm. After all the added substances were dissolved and turned into a colorless uniform solution, the temperature of the water bath was raised to 70°C, 0.01g of ammonium persulfate was added, stirring was continued, and the reaction was carried out at a constant temperature for 6 hours. After natural cooling to room temperature, a microgel solution was obtained, namely poly-N- Isopropylacrylamide, ready to use;

[0052] 2) Take 30mL of the above-p...

Embodiment 2

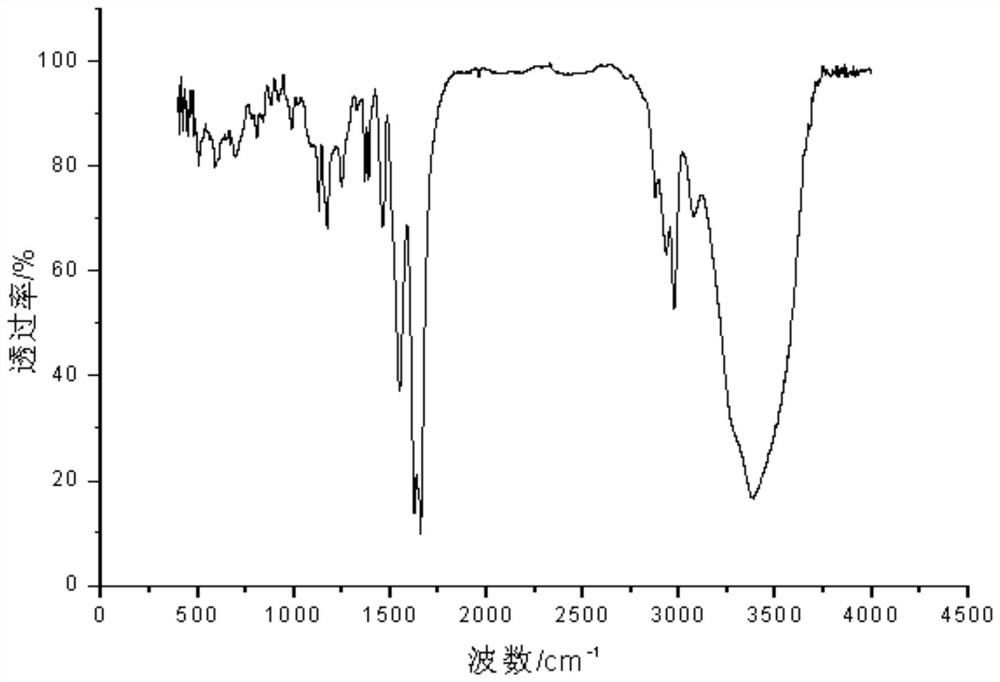

[0054] A kind of bactericide, concrete preparation method is as follows:

[0055] 1) Place a 250mL three-necked flask containing 60mL of distilled water in a water bath, raise the temperature of the water bath to 40°C, and accurately weigh 0.50g of N-isopropylacrylamide and 0.017g of N,N-methylenebispropene Amide, 0.01g methacryloyloxyethyltrimethylammonium chloride and 0.013g sodium lauryl sulfate were added to a 250mL three-necked flask, nitrogen was bubbled, and mechanical stirring was carried out at a speed of 3500 rpm. After all the added substances were dissolved and turned into a colorless uniform solution, the temperature of the water bath was raised to 70°C, 0.01g of ammonium persulfate was added, stirring was continued, and the reaction was carried out at a constant temperature for 6 hours. After natural cooling to room temperature, a microgel solution was obtained, namely poly-N- Isopropylacrylamide, ready to use;

[0056] 2) Take 30mL of the above-prepared microge...

Embodiment 3

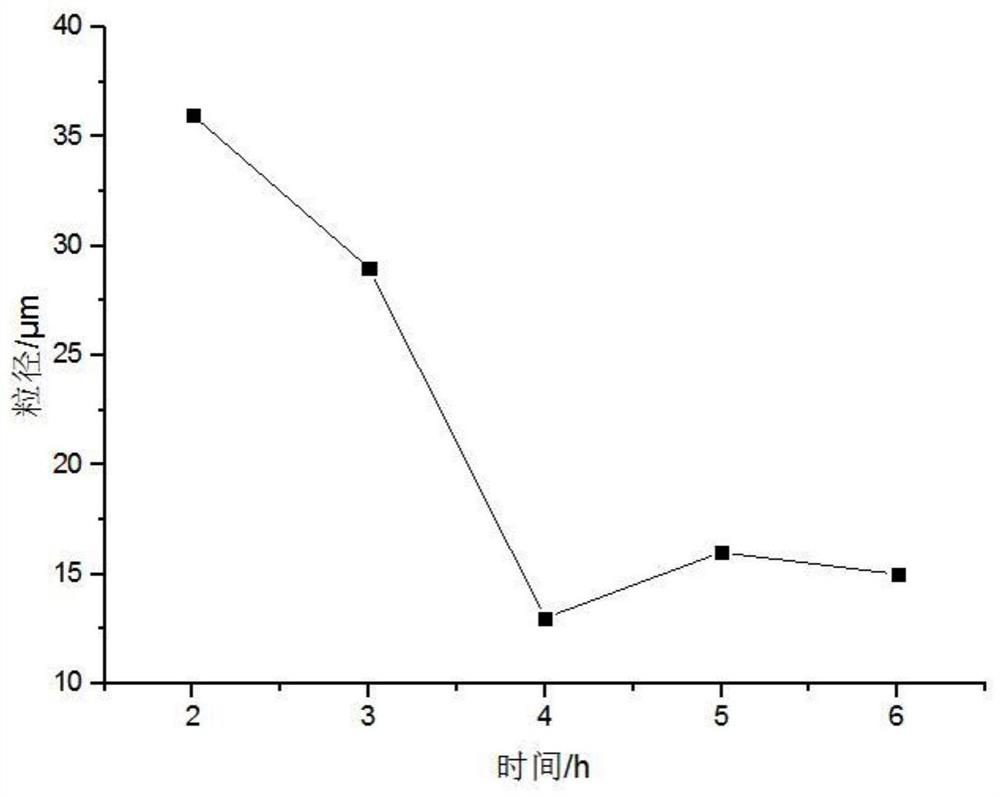

[0058] A kind of bactericide, concrete preparation method is as follows:

[0059] 1) Place a 250mL three-necked flask containing 50mL distilled water in a water bath, raise the temperature of the water bath to 38°C, and accurately weigh 1g of N-isopropylacrylamide and 0.015g of N,N-methylenebisacrylamide , 0.004g methacryloyloxyethyltrimethylammonium chloride and 0.029g sodium lauryl sulfate were added in a 250mL three-necked flask, nitrogen was bubbled, and mechanical stirring was carried out at a speed of 3500 rpm. After all the added substances were dissolved to form a colorless homogeneous solution, the temperature of the water bath was raised to 68°C, 0.013g of ammonium persulfate was added, stirring was continued, and the reaction was carried out at a constant temperature for 4 hours. After natural cooling to room temperature, a microgel solution was obtained, which was poly-N-iso Propylacrylamide, ready to use;

[0060] 2) Take 30mL of the above-prepared microgel solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com