Intelligent responsive sustained-release microsphere and preparation method thereof

An intelligent, microsphere technology, applied in the field of novel microspheres formed by ketal or its derivative-PLGA and its preparation, intelligent responsive slow-release microspheres and its preparation fields, can solve problems such as hypoglycemia, Achieve the effect of improving the encapsulation rate and overcoming hypoglycemia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

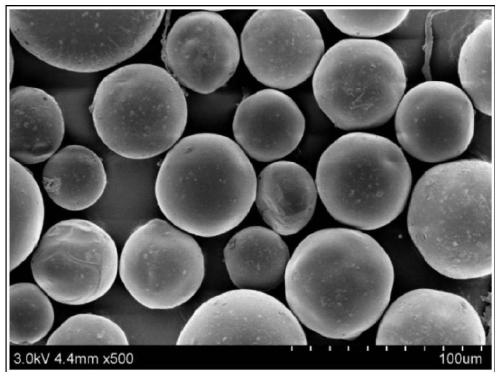

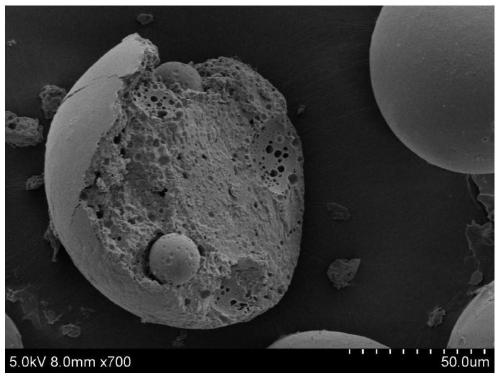

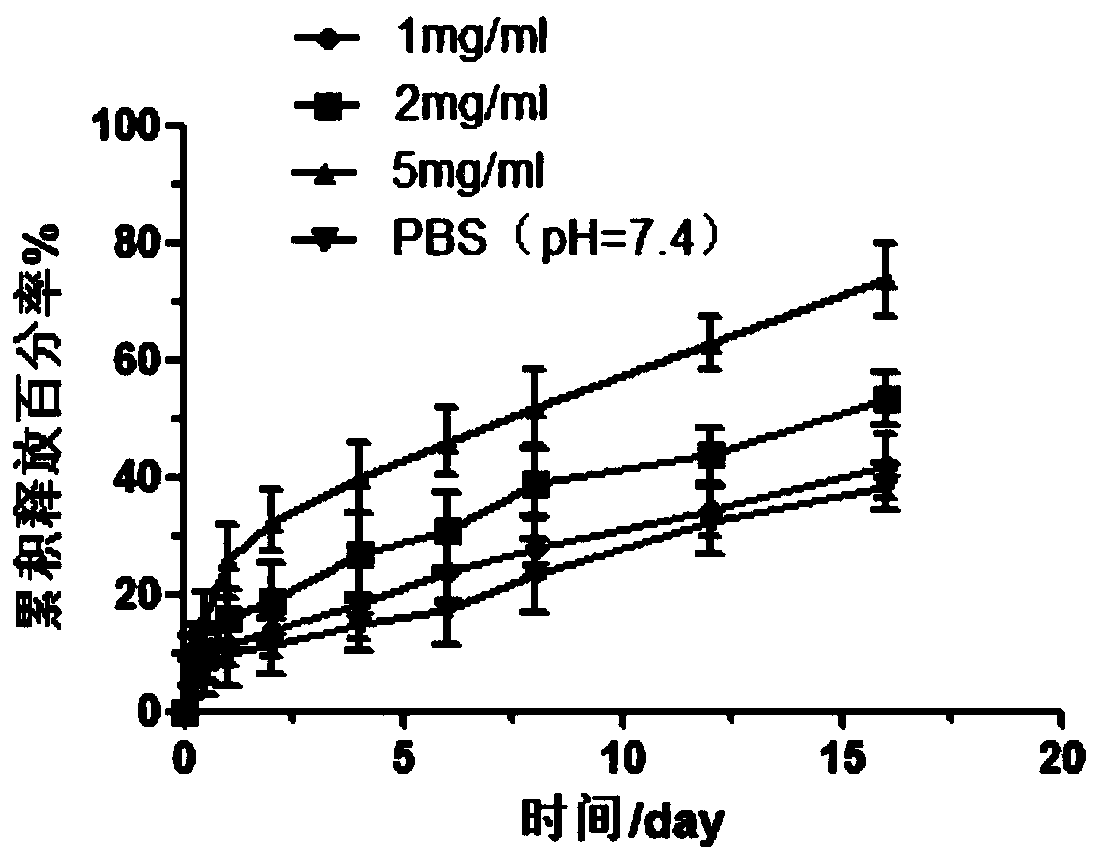

[0046] Example 1 Intelligent responsive slow-release microspheres loaded with insulin

[0047] (1) Prepare two separate oil phases, which are oil phase A: Accurately weigh 20 mg of insulin and dissolve it in 0.1 ml of dimethyl sulfoxide (DMSO), and add the above solution dropwise to 0.9ml of dichloromethane containing 150mg of polyketal (weight average molecular weight 4250); oil phase B: 10mg of glucose oxidase, 10mg of catalase and 300mg of PLGA were dissolved in 2ml of ethyl acetate ;

[0048] (2) Quickly drop the oil phase A into the B phase under the high-speed shear condition of 2000rpm to form the S / O / O phase; quickly drop the S / O / O phase to 200ml mass under the high-speed shear condition of 4000rpm In the PVA aqueous solution with a concentration of 1%, the S / O / O / W phase is formed;

[0049] (3) Stir the emulsion obtained above at 1000 rpm for 1 hour, then stir at 500 rpm for 2 hours, centrifuge the solidified microspheres, wash with deionized water, and freeze-dry to...

Embodiment 2

[0051] Example 2 Intelligent Responsive Slow and Controlled Release Microspheres Loaded with Exenatide

[0052] (1) Prepare two separate oil phases, which are oil phase A: accurately weighed 20 mg of exenatide dissolved in 1 ml of dichloromethane containing 200 mg of polyketal (weight average molecular weight 7250); oil phase B: the Accurately weighed 15mg of glucose oxidase, 15mg of catalase and 200mg of PLGA were dissolved in 1ml of acetone;

[0053] (2) Quickly drop the oil phase A into the B phase under the condition of 3000rpm high-speed shear to form the O / O phase; quickly drop the O / O phase into 200ml of 1% mass concentration under the condition of high-speed shear of 5000rpm In PVA aqueous solution, O / O / W phase is formed;

[0054] (3) Stir the emulsion obtained above at 1200rpm for 1h, then stir rapidly at 600rpm for 2h, centrifuge the solidified microspheres, wash with deionized water, and freeze-dry to obtain the product.

[0055] After testing, the particle size o...

Embodiment 3

[0056] Example 3 Intelligent response slow and controlled release microspheres loaded with glibenclamide

[0057] (1) Prepare two separate oil phases, which are oil phase A: precisely weighed glibenclamide 30mg dissolved in 1.5ml dichloromethane containing 300mg polyketal (weight average molecular weight 6500); oil phase B: mix Accurately weighed 20mg of glucose oxidase, 20mg of catalase and 300mg of PLGA were dissolved in 1.5ml of tetrahydrofuran;

[0058] (2) Quickly drop the oil phase A into the B phase under the condition of 4000rpm high-speed shear to form the O / O phase; quickly drop the O / O phase into 300ml of 1% mass concentration under the condition of high-speed shear of 6000rpm In PVA aqueous solution, O / O / W phase is formed;

[0059] (3) Stir the emulsion obtained above at 1500rpm for 1h, then stir rapidly at 700rpm for 2h, centrifuge the solidified microspheres, wash with deionized water, and freeze-dry to obtain the product.

[0060] After testing, the particle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com