Metal monatomic catalyst and preparation method thereof

A catalyst and metal technology, applied in the field of metal single-atom catalysts and their preparation, can solve the problems of single-atom metal species, poor stability, long process, etc., and achieve the effects of improving catalytic performance, preventing shedding and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

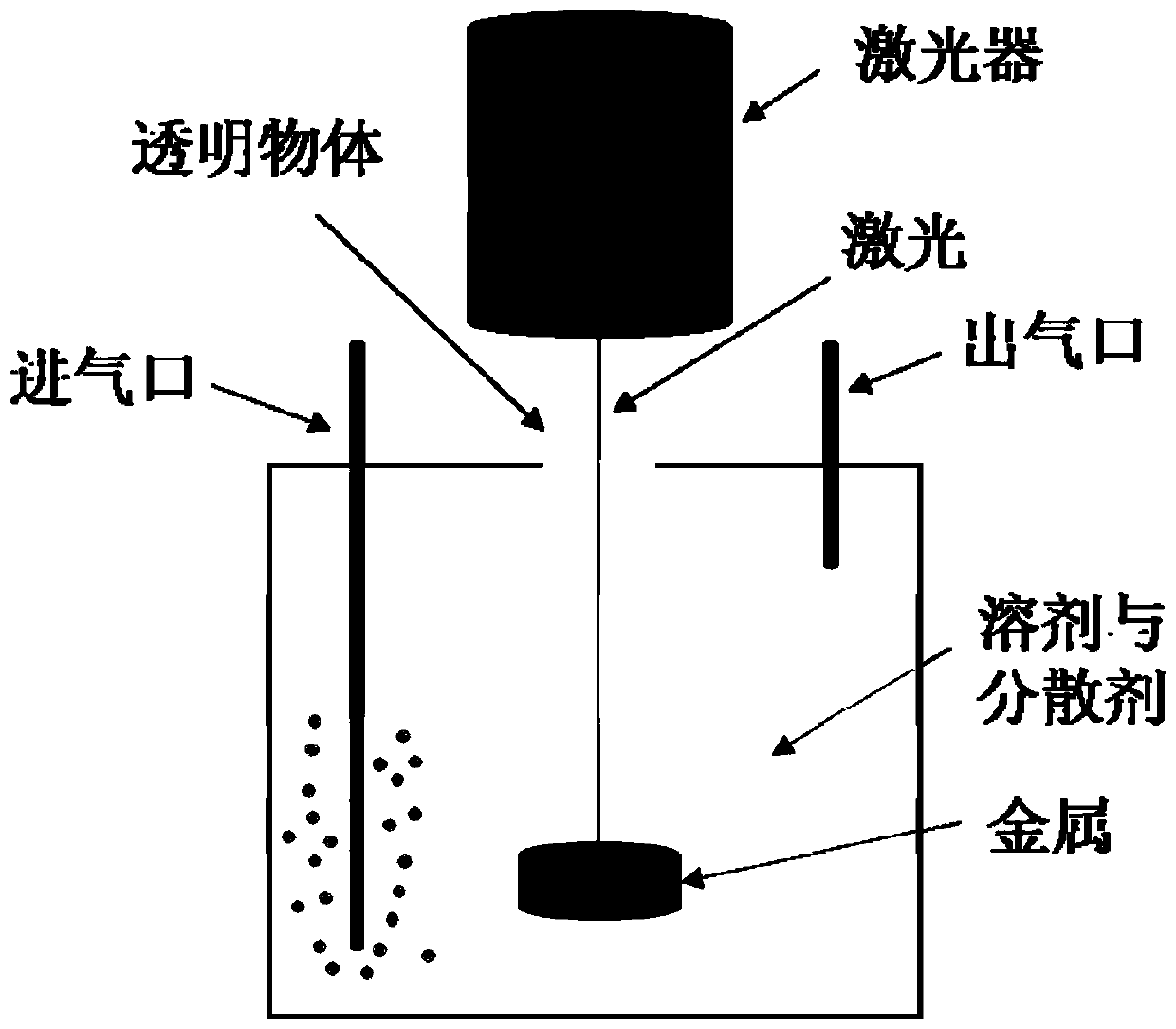

[0043]The embodiment of the present invention provides a method for preparing a metal single-atom catalyst, comprising the following steps:

[0044] S10. Under the first protective gas atmosphere, laser treatment is performed on the mixed solution containing the metal material and the dispersant to obtain a mixed metal single atom solution;

[0045] S20. Mixing the metal single atom mixed solution with the base material and performing a hydrothermal reaction to obtain a precursor loaded with a metal single atom;

[0046] S30. Under the atmosphere of the second protective gas, the precursor is mixed with the nitrogen-containing compound and then sintered to obtain a nitrogen-doped metal single-atom catalyst.

[0047] The preparation method of the metal single-atom catalyst provided by the embodiment of the present invention is to carry out laser treatment on the mixed solution containing the metal material and the dispersant, so that the metal material enters the solution in th...

Embodiment 1

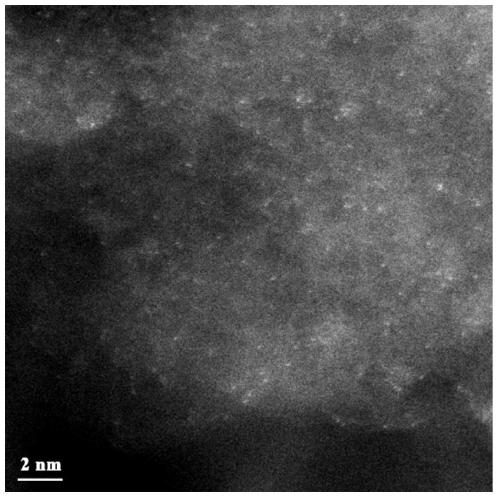

[0071] A metal single-atom catalyst comprising the following preparation steps:

[0072] 1) Put the cobalt metal block into 30ml ethanol solution containing 0.1wt% block polymer P123.

[0073] 2) The solution is fed with excess argon.

[0074] 3) A visible laser with a laser power of 30w irradiates the surface of metal cobalt, so that cobalt atoms enter the solution, and the irradiation time is 0.2h.

[0075] 4) The metal monoatomic dispersed solution was mixed with ZIF-8 by ultrasonic, and reacted in a high-pressure reactor at 80° C. for 5 hours. Centrifugal separation to obtain the ZIF-8 precursor loaded with cobalt single atom;

[0076] 5) After the precursor material is mixed with 20wt% ammonium chloride, it is calcined at 400°C for 2 hours under an argon atmosphere, and finally a metal single-atom catalyst Co-N-C can be obtained. The mass percentage of cobalt atoms is shown in Table 1. The obtained catalyst can be used at 0.1mol / LHClO 4 solution to test the oxygen red...

Embodiment 2

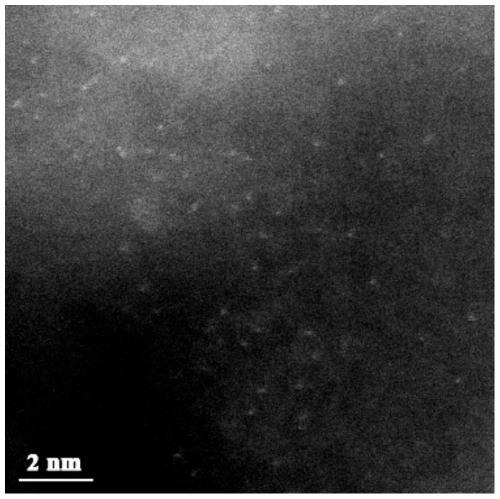

[0078] A metal single-atom catalyst comprising the following preparation steps:

[0079] 1) The cobalt metal powder is placed in a 50ml ethanol solution containing 5wt% P127.

[0080] 2) The solution is fed with excess nitrogen.

[0081] 3) A visible laser with a laser power of 100w irradiates the surface of metal cobalt, so that cobalt atoms enter the solution, and the irradiation time is 0.5h.

[0082] 4) Stir and mix the solution of metal monatomic dispersion with activated carbon, and react in a high-pressure reactor at 120° C. for 6 hours. Centrifugal separation to obtain an activated carbon precursor loaded with cobalt single atoms;

[0083] 5) After the precursor material is mixed with 0.1wt% ammonium nitrate, it is calcined at 1200°C for 5h under an argon atmosphere, and finally the metal single-atom catalyst Co-N-C can be obtained. The mass percentage of cobalt atoms is shown in Table 1. The obtained catalyst can be used Test the oxygen reduction performance in 0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com