Hot extrusion process of bottom outgoing line blank for solid-sealed pole

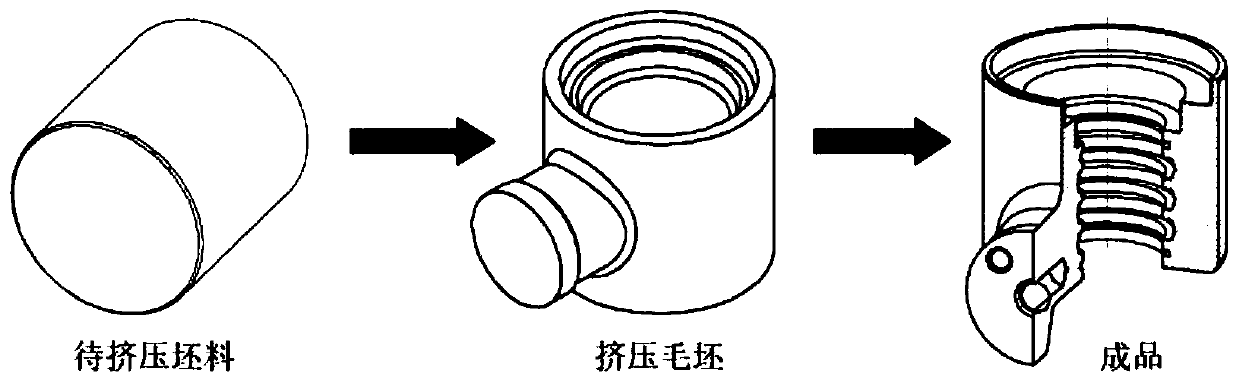

A technology of solid-sealed poles and hot extrusion, which is applied in the field of hot extrusion molding, can solve the problems of great influence on the quality of casting blanks, high mold investment costs, and complex mold structures, so as to shorten the production time, avoid molding difficulties, The effect of improving blank quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

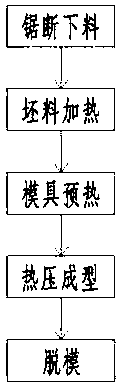

[0027] A hot extrusion process for the bottom-outlet blank for solid-sealed poles, including the following steps:

[0028] S1: sawing and cutting

[0029] The bottom outlet material is T2. Use the 3D drawing software to create a 3D model of the extrusion blank. The simulated weight of the blank is AKg / piece. Considering the material consumption of the blank hot extrusion, the actual feed weight is A×1.03Kg / piece, and then converted to T2 rod. material The cutting length is L;

[0030] S2: billet heating

[0031] Put the sawed bar into the RX6-100-12 box-type resistance furnace, and place them evenly with an interval of 3cm, and no blanks are placed within 30cm of the resistance furnace door; close the furnace door, heat it to 760℃, and then Conduct heat preservation treatment for 15 minutes;

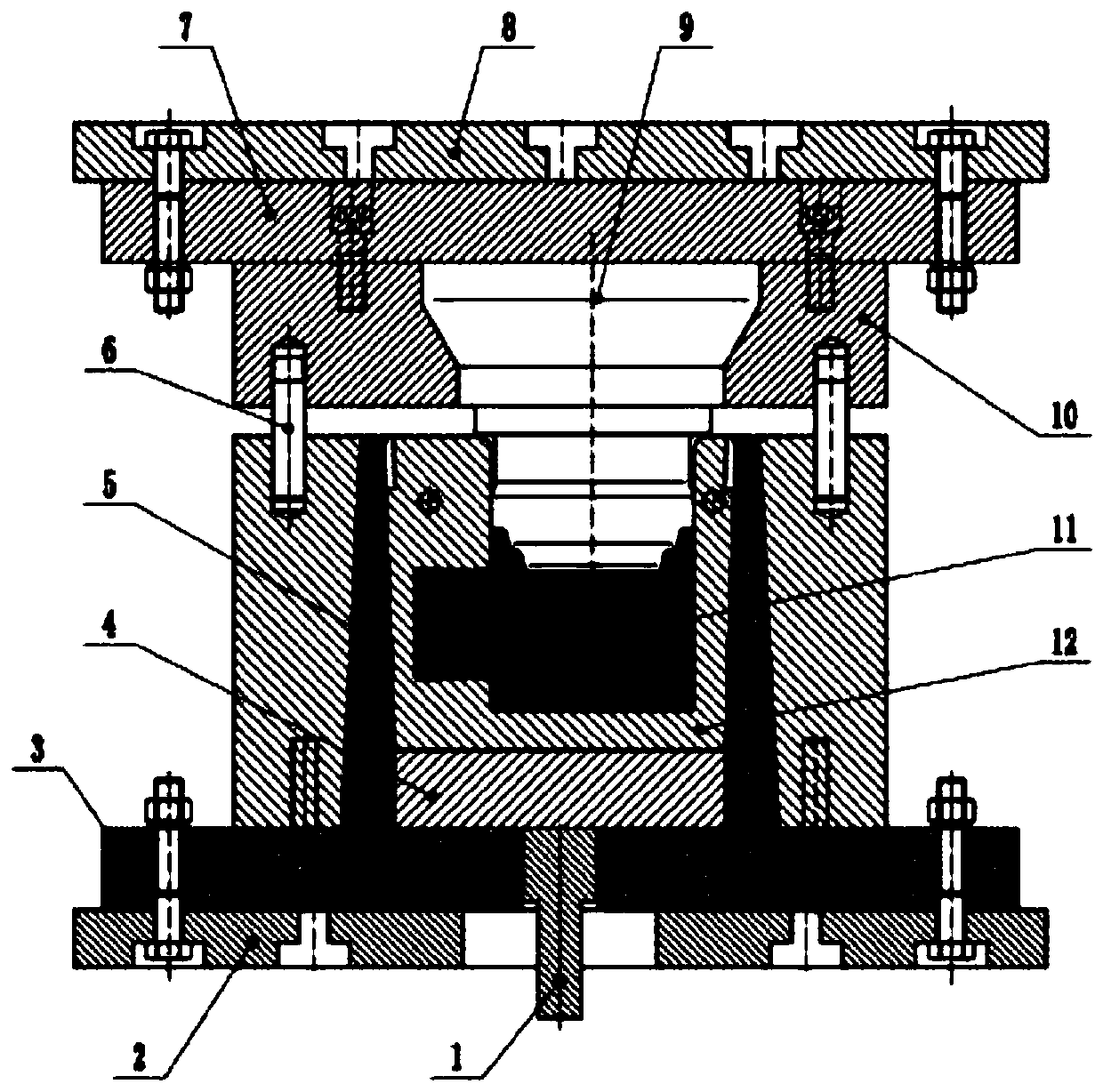

[0032] S3: Mold preheating

[0033] Before the billet is out of the furnace, put the heated billet into the forming mold, preheat the forming mold, detect with an infrared temperature gun, heat ...

Embodiment 2

[0039] A hot extrusion process of the bottom-outlet blank for solid-sealed poles, including the following steps:

[0040] S1: Cutting off the material

[0041] The bottom outlet material is T2. Use the 3D drawing software to create a 3D model of the extrusion blank. The simulated weight of the blank is AKg / piece. Considering the material consumption of the blank hot extrusion, the actual feed weight is A×1.03Kg / piece, and then converted to T2 rod. material The cutting length is L;

[0042] S2: billet heating

[0043] Put the sawed bar into the RX6-100-12 box-type resistance furnace, and place them evenly with an interval of 3cm, and no blanks are placed within 30cm of the door of the resistance furnace; close the furnace door and heat it to 760℃, then Carry out heat preservation treatment for 15 minutes;

[0044] S3: Mold preheating

[0045] Before the billet is out of the furnace, put the heated billet into the forming mold and preheat the forming mold. Under an inert gas atmosphere,...

Embodiment 3

[0051] This embodiment is basically the same as embodiment 2, but the difference is that the sawn bar is placed in the RX6-100-12 box-type resistance furnace, and the space is 4cm, and the resistance furnace door is not within 30cm. Place the blanks; close the furnace door, heat it to 780°C, and perform heat preservation treatment for 15 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com