A kind of preparation method of superfine copper infiltration powder

A copper infiltration, ultra-micro technology, applied in the field of metallurgy, to achieve the effect of maintaining precision, good wettability, increasing density and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

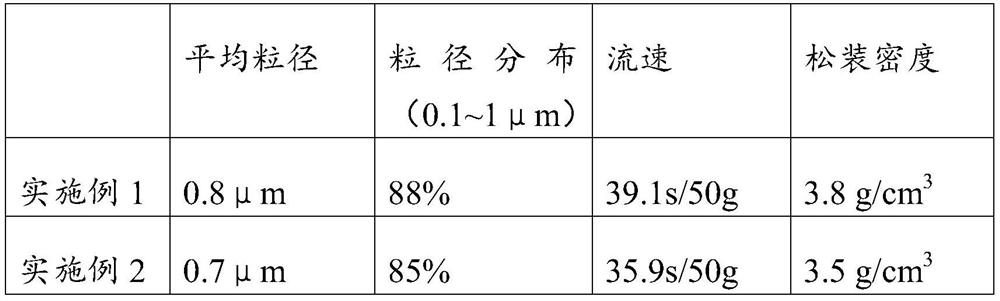

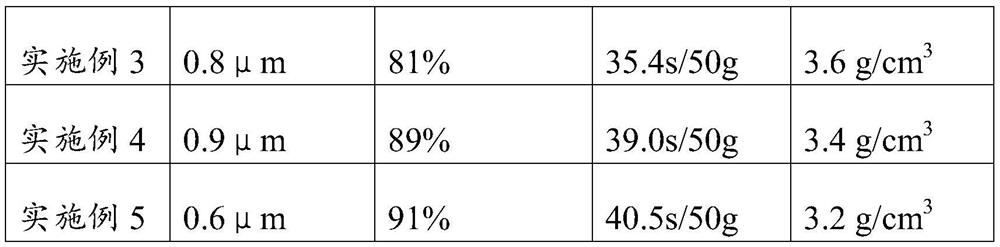

Examples

Embodiment 1

[0018] 100 parts of copper and 2 parts of iron, evaporated by heating in high frequency or intermediate current induction, during evaporation, nitrogen, and nitrogen carrying the powder in the action of the powder in the powder collector, Finally, the solid powder particles I are finally collected on the collector.

[0019] Two parts of 2 parts of iron were mixed with 0.2 parts, 0.1 parts of boron, resulting in alloy ingots, placed in a closed container, at room temperature, vacuum to 1.5 * 10 -3 Pa, then enter high purity hydrogen, raise the pressure to 0.5 MPa, so that the alloy ingot is hydrogenab and the hydrogen is stopped, and the hydrogen is stopped, and the vacuum dehydrogenation is evacuated to obtain solid powder particles II;

[0020] The obtained solid powder particles I were mixed with II, and under normal protection of the solid powder particles I, nitrogen was further grounded to a powder of less than 1.0 μm.

Embodiment 2

[0022] 100 parts of copper and 3 parts of iron, evaporated by heating by itself under high frequency or intermediate current induction, during evaporation, nitrogen, and nitrogen carrying the powder in the action of the powder in the powder collector, Finally, the solid powder particles I are finally collected on the collector.

[0023] 3 parts were mixed with 0.5 parts, 0.15 parts of boron mixture, resulting in an alloy ingot, placed in a closed container, at room temperature, vacuum to 1.8 * 10 -3 Pa, then enter high purity hydrogen, raise the pressure to 0.5 MPa, so that the alloy ingot is hydrogenab and the hydrogen is stopped, and the hydrogen is stopped, and the vacuum dehydrogenation is evacuated to obtain solid powder particles II;

[0024] The obtained solid powder particles I were mixed with II, and under normal protection of the solid powder particles I, nitrogen was further grounded to a powder of less than 1.0 μm.

Embodiment 3

[0026] 100 parts of copper and 2 parts of iron, evaporated by heating in high frequency or intermediate current induction, during evaporation, nitrogen, and nitrogen carrying the powder in the action of the powder in the powder collector, Finally, the solid powder particles I are finally collected on the collector.

[0027] Two parts of 2 parts of iron were mixed with 0.2 parts, 0.1 parts of boron, resulting in alloy ingots, placed in a closed container, at room temperature, vacuum to 1.5 * 10 -3 Pa, reap into high-purity hydrogen, raised to 0.4 to 0.5 MPa, so that the alloy ingot is hydrogenab and the hydrogen is stopped, and the hydrogen is vacuum dehydrogenation to obtain solid powder particles II;

[0028] The obtained solid powder particles I were mixed with II described above, and under nitrogen protection was further grounded with gas to flow, and then placed in a tubular reactor, at normal pressure, inlet oxygen, carbon dioxide mixture The flow rate ratio of oxygen and car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com