Preparation method of two-component medical adhesive

An adhesive, two-component technology, used in pharmaceutical formulations, surgical adhesives, applications, etc., can solve problems such as degradation product toxicity, shorten curing time, and long curing time, achieve reduced pain, low swelling, enhanced The effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1, trimethylolpropane tris(3-mercaptopropionate) (39.86g, 10mmol) was dissolved in 240mL N'N-dimethylformamide, N 2 Bubble 30min to remove the air in the solution, then add 3-(acryloyloxy)-methacrylic acid-2-hydroxypropyl ester (19.28g, 9mmol), N 2 Under the protection of 40 ° C reaction for 24h. After the reaction, the reaction solution was concentrated by a rotary evaporator, and then precipitated in anhydrous ether to obtain a colorless transparent viscous liquid. The product was then redissolved in 40 mL of dichloromethane and precipitated by adding to 400 mL of diethyl ether. Repeat the above dissolution-precipitation operation 3 times, and vacuum dry to obtain a colorless viscous hyperbranched polymer component A, which is recorded as HBP1 and has a molecular weight of 8 kDa.

[0029] Step 2: Weigh 40g of polyethylene glycol and dissolve it in 150mL of toluene, raise the temperature to 140°C and reflux for 3 hours through the water separator to remove the m...

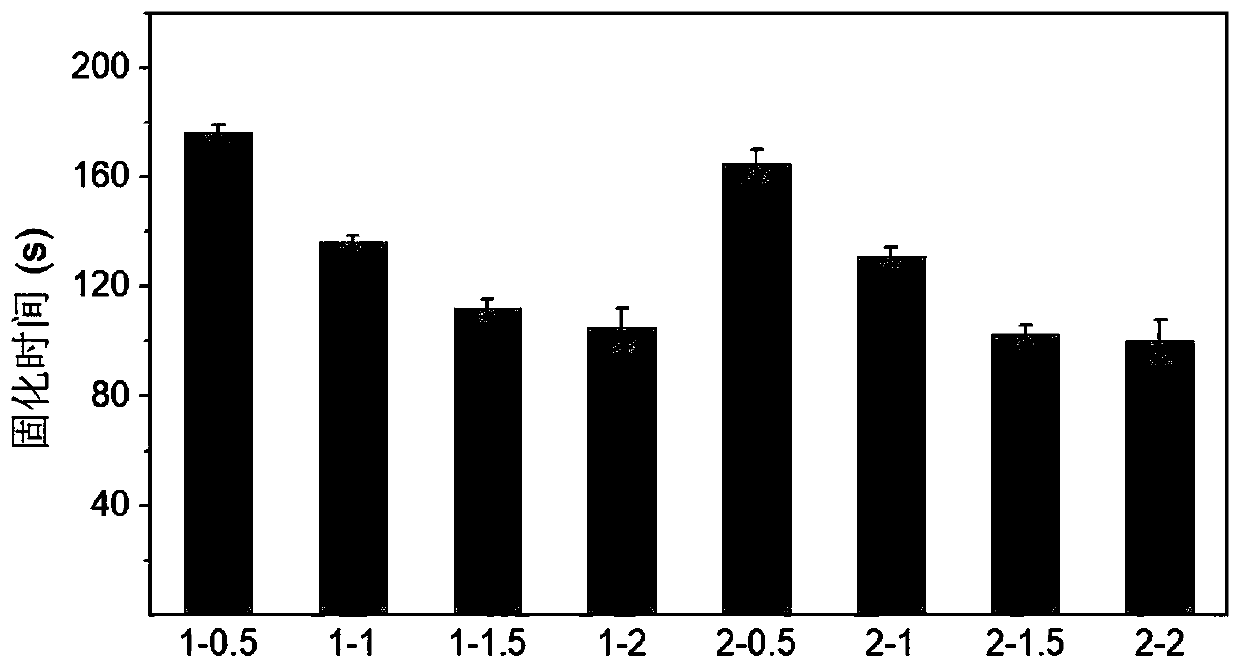

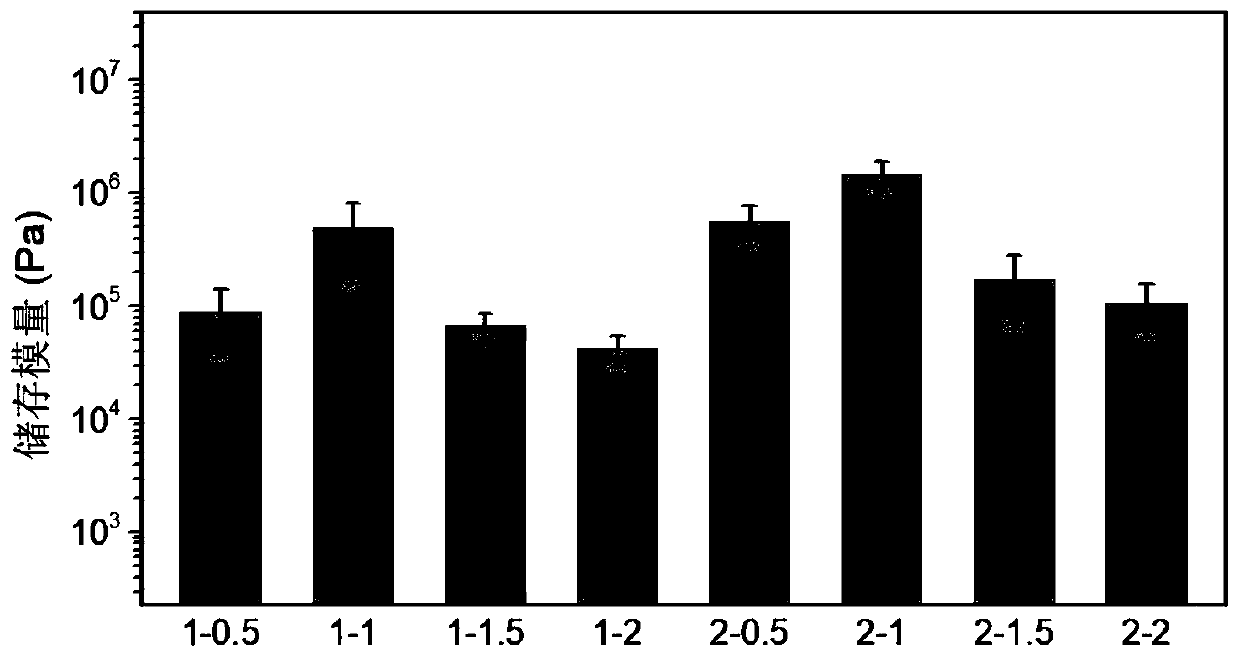

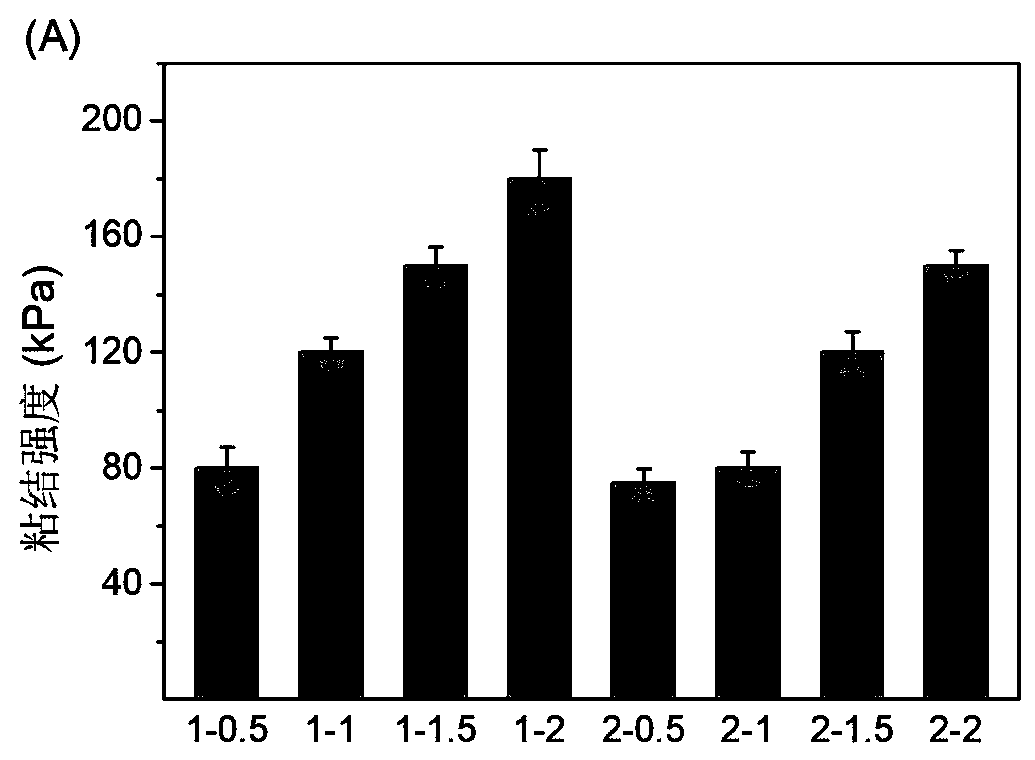

Embodiment 2

[0032] Same as Example 1, but change the addition amount of isocyanate-functionalized polyethylene glycol (PEG-NCO, 1 mol in terms of isocyanate functional group) in step 3), and the rest of the operations are the same to obtain an adhesive, which is named 1-1.

Embodiment 3

[0034] Same as Example 1, but change the addition amount of isocyanate-functionalized polyethylene glycol (PEG-NCO, 1.5 mol in terms of isocyanate functional group) in step 3), and the rest of the operations are the same to obtain the adhesive, named 1-1.5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com