Preparation method of magnetized porous composite material adsorbent

A porous composite material and adsorbent technology, applied in chemical instruments and methods, alkali metal compounds, other chemical processes, etc., can solve the problems of complete separation and recovery of nanomaterials, and achieve good reusability, high adsorption capacity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

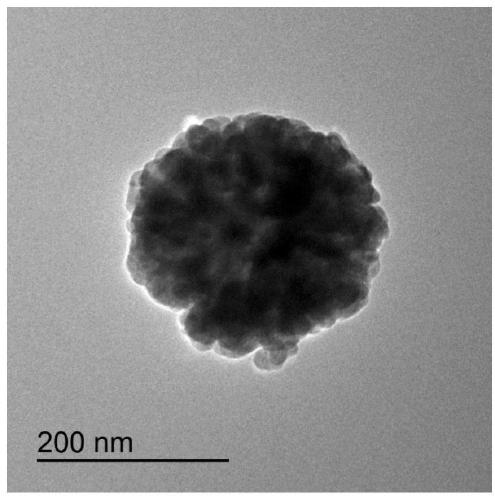

[0037] 1. Fe 3 o 4 Synthesized by hydrothermal method: weigh 5.7 g of sodium acetate and dissolve it in 50 mL of ethylene glycol solution, heat it to fully dissolve, and dissolve 2.7 g of FeCl 3 ·6H 2 O was dissolved in the above solution and stirred at 50 °C for 1 h. Then the mixed solution was transferred to a 100 mL polytetrafluoroethylene autoclave and heated to 180 °C for 8 hours. Naturally cooled to room temperature, the black magnetic microspheres were collected magnetically, and washed three times with ethanol and deionized water respectively. Dry in a vacuum oven at 60°C for 3 hours. get the required Fe 3 o 4 granular products.

[0038] 2. Thioglycolic acid modification of Fe 3 o 4 : 1 g of the above-prepared Fe 3 o 4 Ultrasonic dispersion in 80 mL of thioglycolic acid (thioglycolic acid) (1.74 mmol / L) ethanol solution, the temperature was controlled at 30 °C, and the power was 10 W / cm 2 , ultrasonic treatment with a frequency of 30 kHz for 3 minutes; then...

Embodiment 2

[0045] 1. Weigh 5.7 g of sodium acetate and dissolve it in 50 mL of ethylene glycol solution and heat it to fully dissolve, and 2.7 g of FeCl 3 ·6H 2 O was dissolved in the above solution and stirred at 50 °C for 1 h. Then the mixed solution was transferred to a 100 mL polytetrafluoroethylene autoclave and heated to 180 °C for 8 hours. Naturally cooled to room temperature, the black magnetic microspheres were collected magnetically, and washed three times with ethanol and deionized water respectively. Dry in a vacuum oven at 60°C for 3 hours. get the required Fe 3 o 4 granular products.

[0046] 2. Take 1 g of Fe prepared above 3 o 4 Ultrasonic dispersion in 80 mL of thioglycolic acid (thioglycolic acid) (1.74 mmol / L) ethanol solution, the temperature was controlled at 30 °C, and the power was 5 W / cm 2 , ultrasonic treatment at a frequency of 15 kHz for 5 minutes; then modified for 5 minutes under the condition of a rotating permanent magnet with a residual magnetic st...

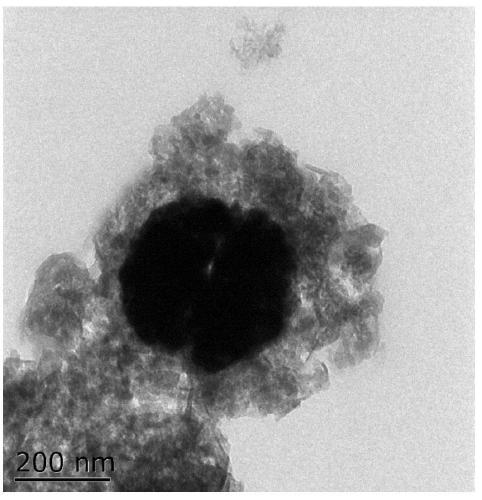

Embodiment 3

[0053] 1. Weigh 5.7 g of sodium acetate and dissolve it in 50 mL of ethylene glycol solution and heat it to fully dissolve, and 2.7 g of FeCl 3 ·6H 2 O was dissolved in the above solution and stirred at 50 °C for 1 h. Then the mixed solution was transferred to a 100 mL polytetrafluoroethylene autoclave and heated to 200 °C for 8 hours. Naturally cooled to room temperature, the black magnetic microspheres were collected magnetically, and washed three times with ethanol and deionized water respectively. Dry in a vacuum oven at 60°C for 3 hours. get the required Fe 3 o 4 granular products.

[0054] 2. Add 1 g of the thus prepared Fe 3 o 4 Ultrasonic dispersion was carried out in 80 mL of thioglycolic acid (1.74 mmol / L) ethanol solution, the temperature was controlled at 30°C, and the power was firstly used at 10 W / cm 2 , ultrasonic treatment with a frequency of 30 kHz for 3 minutes; then modified for 7 minutes under the condition of a rotating permanent magnet with a resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com