Lithium precipitation crystallization method for preparing snowflake-like single crystal high-purity lithium carbonate

A high-purity lithium carbonate, lithium carbonate technology, applied in the direction of lithium carbonate; / acid carbonate, etc., can solve the problem that lithium carbonate cannot form a snowflake-like single crystal large granular structure, easy to agglomerate, agglomerate, and clump. It is beneficial to precipitation and separation, not easy to agglomerate, and the crystal lattice size is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Points not described in the following examples are the same as those described above.

[0063] Concrete process method step and the control of technical parameter are as follows:

[0064] A lithium precipitation and crystallization method for preparing snowflake-shaped single crystal high-purity lithium carbonate disclosed by the invention uses lithium solution as a raw material; it comprises the following method steps,

[0065] 1) prepare standard sodium carbonate solution, add pure water together in reaction device or be called reactor device, so-called pure water can be deionized water, heat under constant stirring, add sodium carbonate, constant temperature is 80 ℃; Prepare sodium carbonate saturated solution under this constant temperature condition, the stirring velocity of the reactor of control reaction unit is 60 revs / min; The concentration of the standard sodium carbonate solution that controls making is 260g / L; Be standard sodium carbonate solution;

[0066]...

Embodiment 2

[0080] Explanation of the technical terms in the description of the present invention:

[0081] (1) Lithium solution: refers to the compound solution containing lithium. That is to say, the lithium-containing solution obtained in the lithium extraction process, the lithium solution of the present invention is lithium-containing compound solutions such as lithium sulfate, lithium chloride or lithium phosphate;

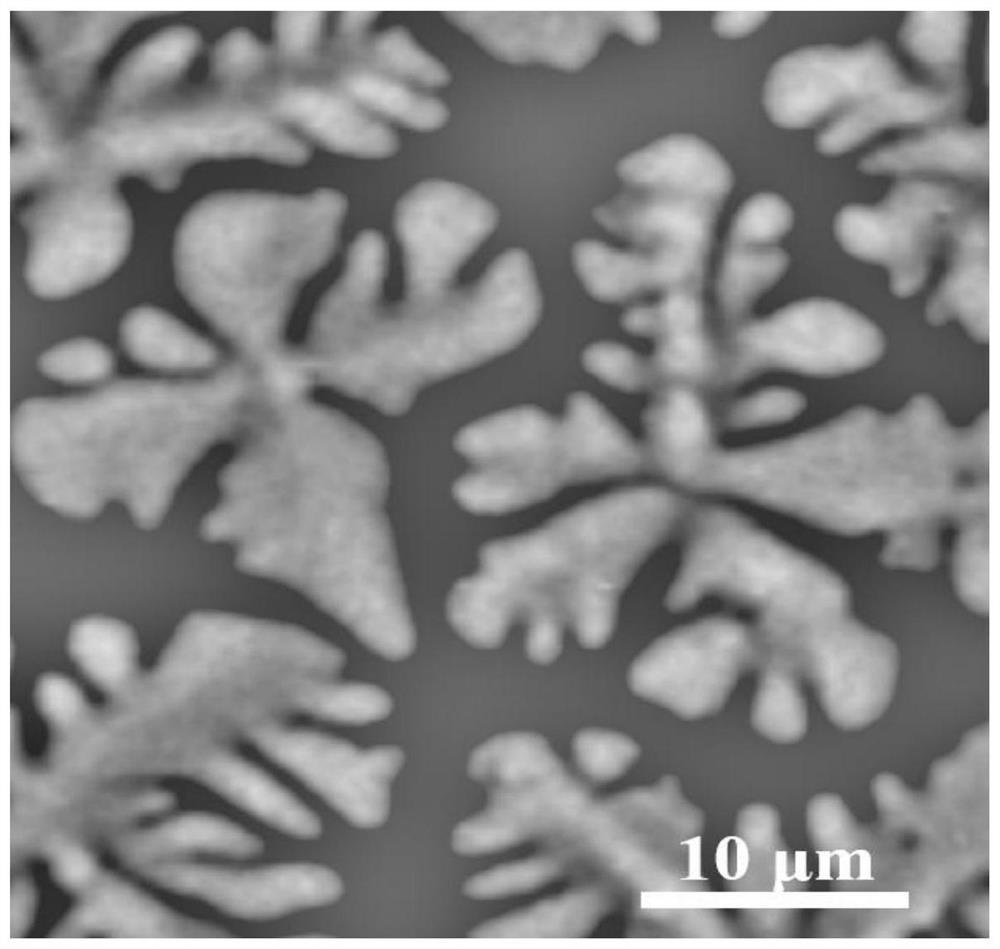

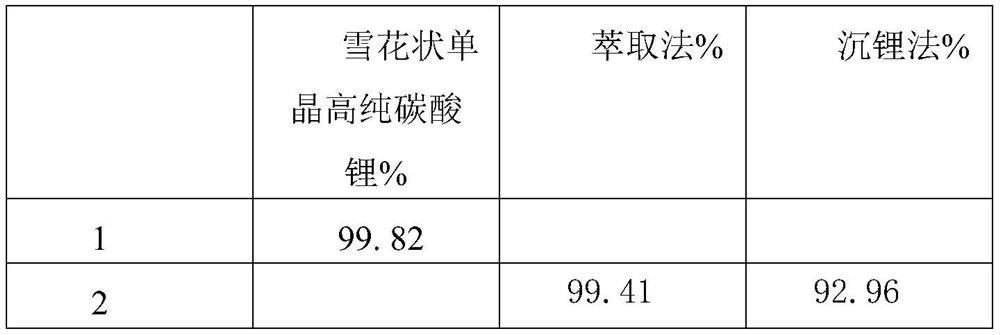

[0082] (2) Snowflake-like single-crystal high-purity lithium carbonate or snowflake-like single-crystal large-grained lithium carbonate: Lithium carbonate has a single-crystal structure, and its crystal structure microscopic appearance resembles snowflakes, and the average grain size is larger than the conventional grain size. Therefore, it is named "snowflake-shaped" single crystal large particle lithium carbonate or snowflake-shaped single crystal high-purity lithium carbonate;

[0083] (3) Lithium carbonate adsorption mother nucleus: Suspend the ultrafine powder lithi...

Embodiment 3

[0107] Explanation of the technical terms in the description of the present invention:

[0108] (1) Lithium solution: refers to the compound solution containing lithium. That is to say, the lithium-containing solution obtained in the lithium extraction process, the lithium solution of the present invention is lithium-containing compound solutions such as lithium sulfate, lithium chloride or lithium phosphate;

[0109] (2) Snowflake-like single-crystal high-purity lithium carbonate or snowflake-like single-crystal large-grained lithium carbonate: Lithium carbonate has a single-crystal structure, and its crystal structure microscopic appearance resembles snowflakes, and the average grain size is larger than the conventional grain size. Therefore, it is named "snowflake-shaped" single crystal large particle lithium carbonate or snowflake-shaped single crystal high-purity lithium carbonate;

[0110] (3) Lithium carbonate adsorption mother nucleus: Suspend the ultrafine powder lit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com