Polyurethane adhesive, preparation method thereof and aluminum honeycomb plate

A technology of polyurethane adhesive and polyurethane prepolymer, applied in polyurea/polyurethane adhesives, adhesives, adhesive additives, etc., can solve problems such as bonding strength attenuation, achieve enhanced bonding performance, and ensure bonding Strength and flexibility, the effect of solving the roller peel strength and flat tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

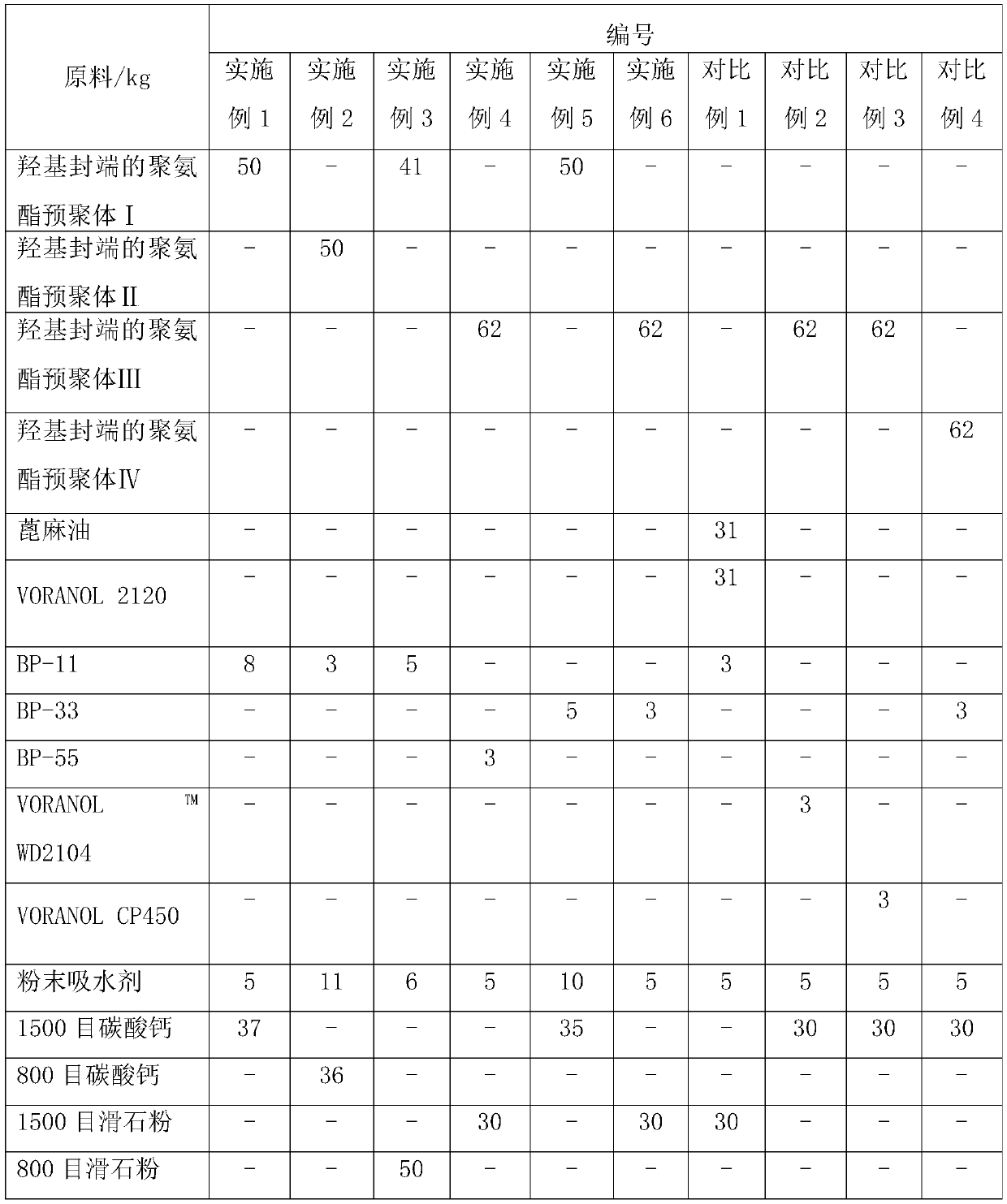

Embodiment 1

[0051] A kind of polyurethane adhesive, comprises A component and B component, and described B component is polymethylene polyphenyl polyisocyanate, and consumption is 25kg, and described A component comprises following raw material: Hydroxy-terminated 50kg of polyurethane prepolymer I, 8kg of polyether polyol BP-11 (average molecular weight 400), 5kg of powdered water absorbent (3A molecular sieve is selected) and 37kg of 1500 mesh calcium carbonate. The polyurethane prepolymer I of described hydroxyl termination comprises following raw material: castor oil 41kg, polypropylene glycol (choose VORANOL TM WD2104, the average molecular weight is 400) is 41kg, 3 kg of R-7162, 3 kg of 2-ethyl-1,3-hexanediol, 2 kg of liquid absorbent SL-201, and 10 kg of MDI-100.

[0052] In the present embodiment, the preparation method of the polyurethane adhesive is as follows:

[0053] 1) Weigh castor oil and polypropylene glycol in proportion, stir and mix evenly, vacuumize and remove water ...

Embodiment 2

[0057] A kind of polyurethane adhesive, comprises A component and B component, and described B component is polymethylene polyphenyl polyisocyanate, and consumption is 25kg, and described A component comprises following raw material: Hydroxy-terminated 50kg of polyurethane prepolymer II, 3kg of polyether polyol BP-11 (average molecular weight 400), 11kg of powdered water absorbent (3A molecular sieve is selected) and 36kg of 800 mesh calcium carbonate. The polyurethane prepolymer II of described hydroxyl termination comprises following raw material: castor oil 41kg, polypropylene glycol (choose VORANOL TM WD2104 (average molecular weight: 400) is 41kg, SPC-8973N is 3kg, 2-ethyl-1,3-hexanediol is 3kg, liquid absorbent SL-201 is 2kg and Lupranate 251 is 10kg.

[0058] In the present embodiment, the preparation method of the polyurethane adhesive is as follows:

[0059] 1) Weigh castor oil and polypropylene glycol in proportion, stir and mix evenly, vacuumize at 110°C to remove ...

Embodiment 3

[0063] A kind of polyurethane adhesive, comprises A component and B component, and described B component is polymethylene polyphenyl polyisocyanate, and consumption is 25kg, and described A component comprises following raw material: Hydroxy-terminated Polyurethane prepolymer Ⅰ is 41kg, polyether polyol BP-11 (average molecular weight is 400) 5kg, powder water absorbent (3A molecular sieve is selected) 6kg and 800 mesh talc powder 50kg. The polyurethane prepolymer I of described hydroxyl termination comprises following raw material: castor oil 41kg, polypropylene glycol (choose VORANOL TM WD2104, the average molecular weight is 400) is 41kg, 3 kg of R-7162, 3 kg of 2-ethyl-1,3-hexanediol, 2 kg of liquid absorbent SL-201, and 10 kg of MDI-100.

[0064] In this example, the preparation method of the polyurethane adhesive is the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com