Treatment method for modifying metal passivation film through dielectric barrier discharge

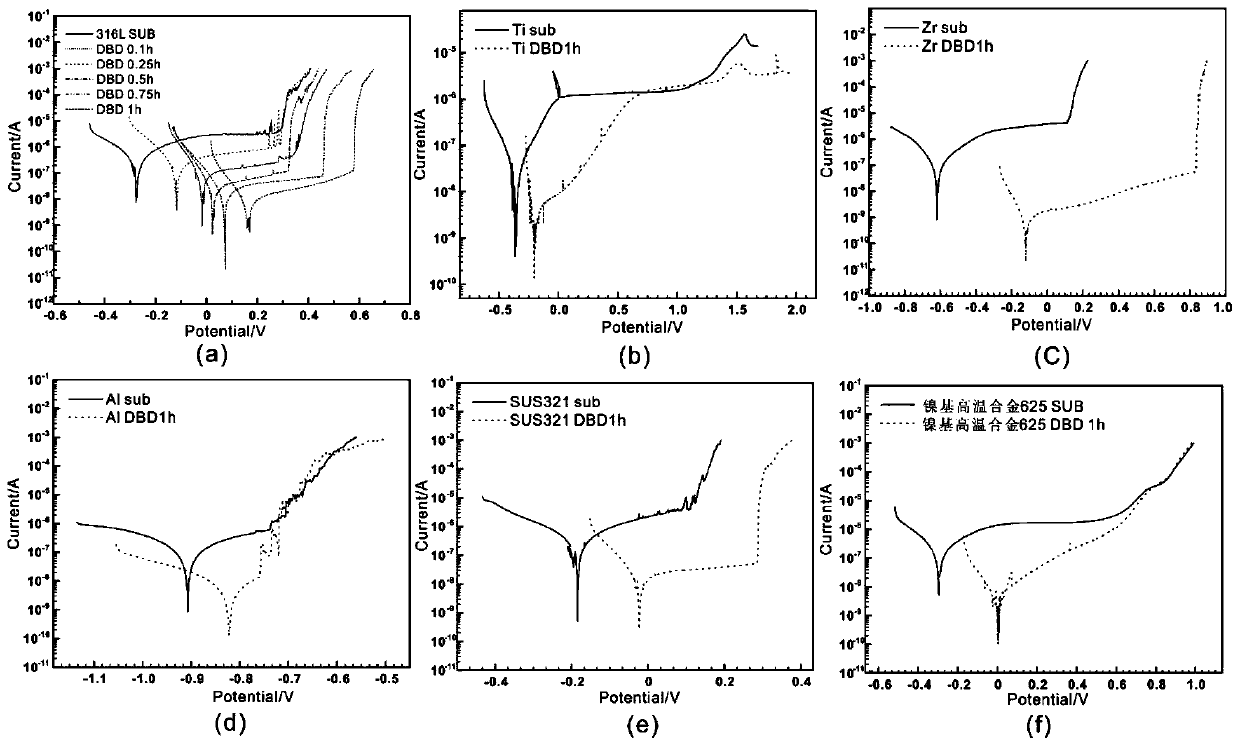

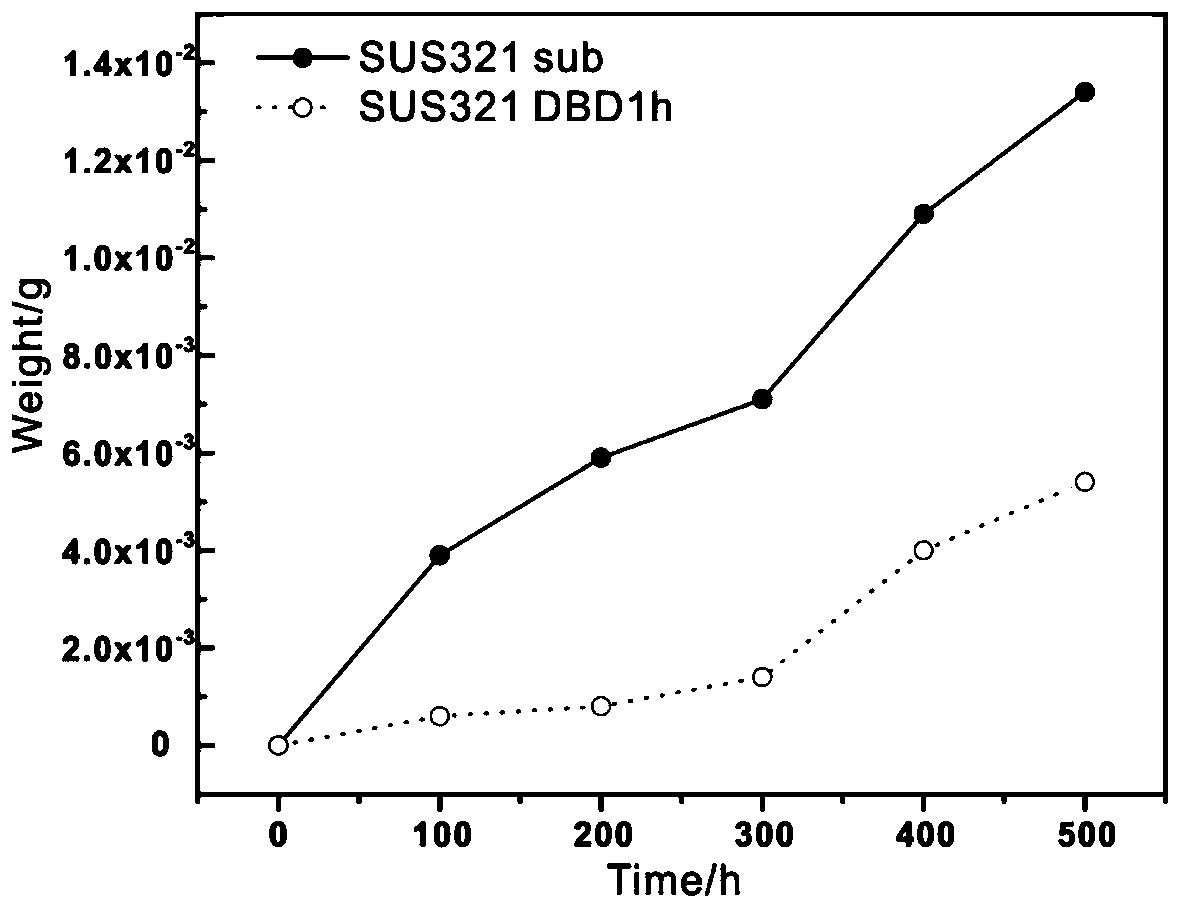

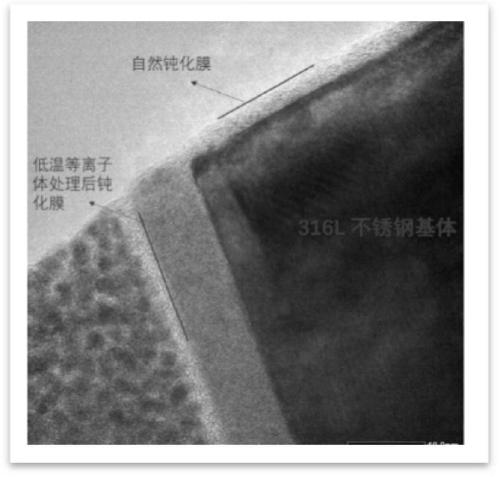

A technology of dielectric barrier discharge and metal passivation, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of waste of resources and energy, unenvironmental treatment liquid, poor adhesion of substrate, etc. The effect of increased rate, improved chemical stability of film, improved corrosion resistance and high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Grind the zirconium metal to be treated to 2000# sandpaper, ultrasonically wash it in absolute ethanol and acetone for 1 min, and the ultrasonic power is 50W, and then dry it in a drying oven (temperature 30°C) for 1 h. After processing, it is stored in a vacuum tank (vacuum degree 1Pa). Before the treatment starts, preheat the double dielectric barrier discharge apparatus (that is, a kind of low-temperature plasma equipment), and set the device parameters, the discharge gap is 6mm, and the discharge voltage is 30V. Subsequently, the sample to be processed was placed between the dielectric plates, the frequency was adjusted to a stable current output, and the processing atmosphere was air (1 atm). After 0.5h of dielectric barrier discharge treatment, the power can be turned off and the treated samples can be taken out.

Embodiment 2

[0032] Grind the metal aluminum to be treated to 2000# sandpaper, ultrasonically wash in absolute ethanol and acetone for 1 min respectively, and the ultrasonic power is 50W, and then dry in a drying oven (temperature 40°C) for 1 h. After processing, it is stored in a vacuum tank (vacuum degree 10Pa). Before the treatment starts, preheat the double dielectric barrier discharge apparatus (that is, a kind of low-temperature plasma equipment), and set the device parameters, the discharge gap is 10mm, and the discharge voltage is 80V. Subsequently, the sample to be processed was placed between the dielectric plates, the frequency was adjusted to a stable current output, and the processing atmosphere was air (1 atm). After 5 hours of dielectric barrier discharge treatment, the power can be turned off and the treated samples can be taken out.

Embodiment 3

[0034] The metal 316L stainless steel to be treated was ground to 2000# sandpaper, ultrasonically washed in absolute ethanol and acetone for 5 min, and the ultrasonic power was 30W, and then dried in a drying oven (temperature 35°C) for 1 h. After processing, store it in a vacuum tank (vacuum degree below 5Pa). Before the treatment starts, preheat the double dielectric barrier discharge apparatus (that is, a kind of low-temperature plasma equipment), and set the device parameters, the discharge gap is 8mm, and the discharge voltage is 50V. Subsequently, the sample to be processed was placed between the dielectric plates, the frequency was adjusted to a stable current output, and the processing atmosphere was air (1 atm). After 3 hours of dielectric barrier discharge treatment, the power can be turned off and the treated samples can be taken out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com