Novel freeze dryer capable of recovering condensate water and operating method of freeze dryer

An operation method and condensed water technology, applied in the direction of irreversible cycle compressors, refrigerators, drying, etc., can solve the problems of high energy consumption, long time required, energy waste, etc., to achieve full and reasonable use of heat, improve batch production Production efficiency and the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

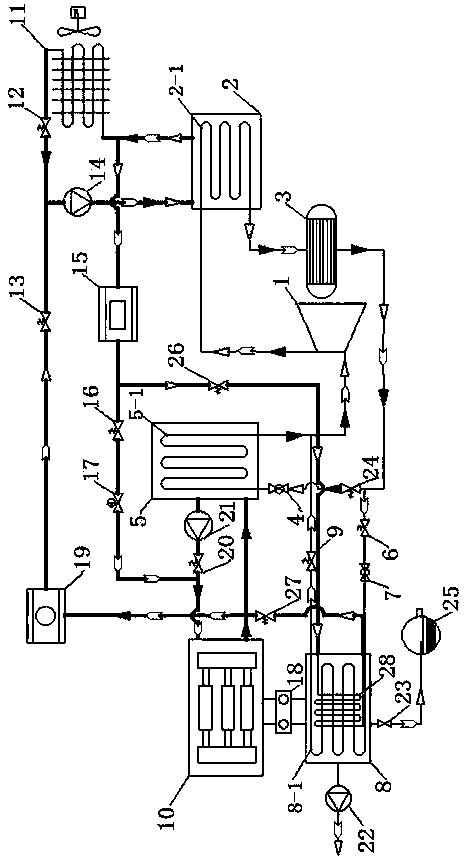

[0034] Such as figure 1 As shown, a new freeze dryer that can recover condensed water includes four parts: a refrigeration system, a condensed water recovery system, a waste heat recovery heating system, and a defrosting system. The refrigeration system consists of a refrigeration compressor 1, a condenser 2, and a storage The liquid tank 3, the first throttle valve 4, the fifth solenoid valve 24, the evaporator 5, the first solenoid valve 6, the second throttle valve 7, the cold trap 8, and the ninth solenoid valve 9; the condensed water recovery system consists of Freeze-drying box 10, box well valve 18, vacuum pump 22, waste heat recovery heating system consists of radiator 11, second solenoid valve 12, sixth solenoid valve 13, first circulation pump 14, heater 15, third solenoid valve 16 , an electric valve 17, an oil tank 19, a fourth s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com