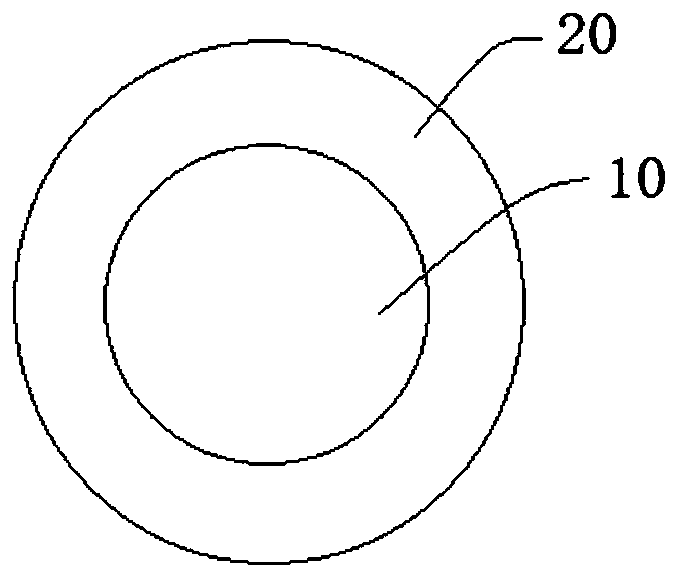

Composite externally-coated positive electrode material preparation method thereof, positive electrode and lithium ion battery

A positive electrode material and outer coating technology, which is applied in the field of composite outer coated positive electrode material and its preparation, positive electrode and lithium ion battery, and can solve problems such as high working voltage, large specific energy, and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

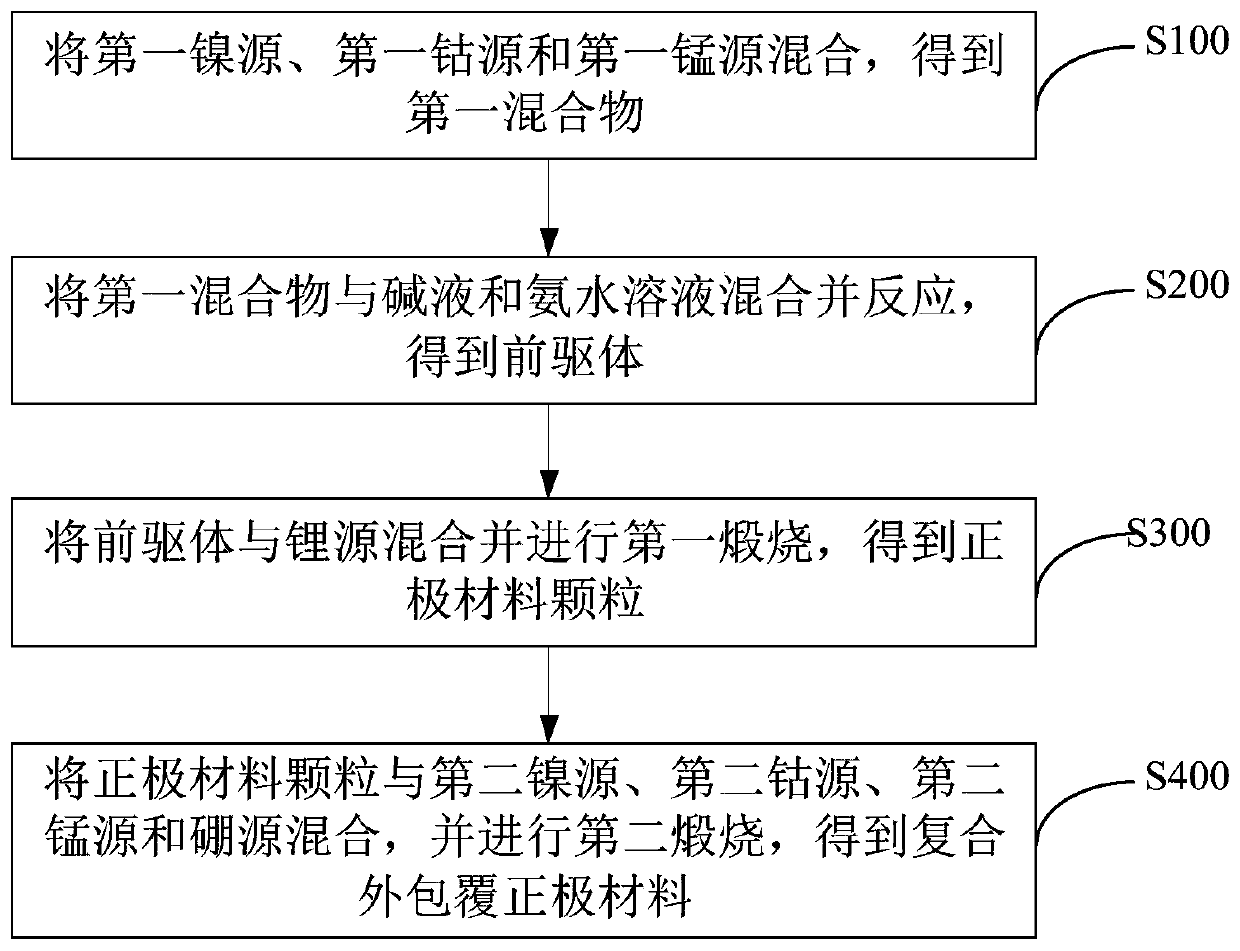

Method used

Image

Examples

Embodiment 1

[0066] Precursor synthesis: Weigh nickel sulfate (99%), cobalt sulfate (99%) and manganese sulfate (99%) crystalline powder according to the molar ratio of nickel, cobalt, and manganese as 7:1:2, and mix and dissolve them in Prepare nickel-cobalt-manganese ternary mixture A with a total concentration of 0.5-1.5mol / L with water, then prepare 6mol / L sodium hydroxide lye B, and 9mol / L ammonia solution C to simultaneously add nickel-cobalt-manganese ternary mixture In A, the ternary 712 precursor is synthesized by reaction. After the synthesis is completed, it is washed, dehydrated, and dried to obtain the finished precursor. The D50 particle size of the finished precursor is about 10 microns.

[0067] First firing of the positive electrode: Weigh a certain amount of the precursor product D and lithium hydroxide E for high-mixer mixing. The precursor and lithium hydroxide are fully mixed at a mass ratio of 1:1.05. Under an oxygen atmosphere, at 950 Calcined for 12 hours at a tempe...

Embodiment 2

[0073] Precursor synthesis: Weigh nickel nitrate (99%), cobalt nitrate (99%) and manganese nitrate (99%) crystalline powders according to the molar ratio of nickel, cobalt, and manganese as 8:1:1, and mix and dissolve them in Water is prepared to obtain a nickel-cobalt-manganese ternary mixture A with a total concentration of 0.5-1.5mol / L, and then 7mol / L sodium hydroxide lye B is prepared, and 10mol / L ammonia solution C is simultaneously added to the nickel-cobalt-manganese ternary mixture React in liquid A to synthesize the ternary 811 precursor. After the synthesis is completed, wash, dehydrate, and dry to obtain the finished precursor. The D50 particle size of the finished precursor is about 10 microns.

[0074] First firing of the positive electrode: Weigh a certain amount of the precursor product D and lithium hydroxide E for high-mixer mixing. The precursor and lithium hydroxide are fully mixed at a mass ratio of 1:1.04. Under an oxygen atmosphere, at 850 degrees Celsius...

Embodiment 3

[0080] Precursor synthesis: take nickel chloride (99%), cobalt chloride (99%) and manganese chloride (99%) crystalline powder according to the molar ratio of nickel, cobalt, manganese is 88:9:3, and its Mix and prepare the nickel-cobalt-manganese ternary mixture A with a total concentration of 0.5-1.5mol / L, then prepare 8mol / L sodium hydroxide lye B and 8mol / L ammonia solution C and simultaneously add nickel-cobalt-manganese ternary mixture React in liquid A to synthesize the ternary 88 precursor. After the synthesis is completed, wash, dehydrate, and dry to obtain the finished precursor. The D50 particle size is about 10 microns.

[0081] First firing of the positive electrode: Weigh a certain amount of the precursor finished product D and lithium hydroxide E for high-mixer mixing. The precursor and lithium hydroxide are fully mixed at a mass ratio of 1:1.03. Under an oxygen atmosphere, at 750 Calcined for 12 hours at a temperature of 100 degrees Celsius to obtain a fired mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com