Preparation method of potassium niobate/alpha-iron oxide heterogeneous photocatalyst

A technology of photocatalyst and iron oxide, which is applied in the field of photocatalysis, can solve the problems that the separation efficiency of photogenerated carriers needs to be further improved, cannot make full use of the visible light of the sun, and the band gap is large, so as to achieve the suppression of electron-hole recombination, time Short, separation-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

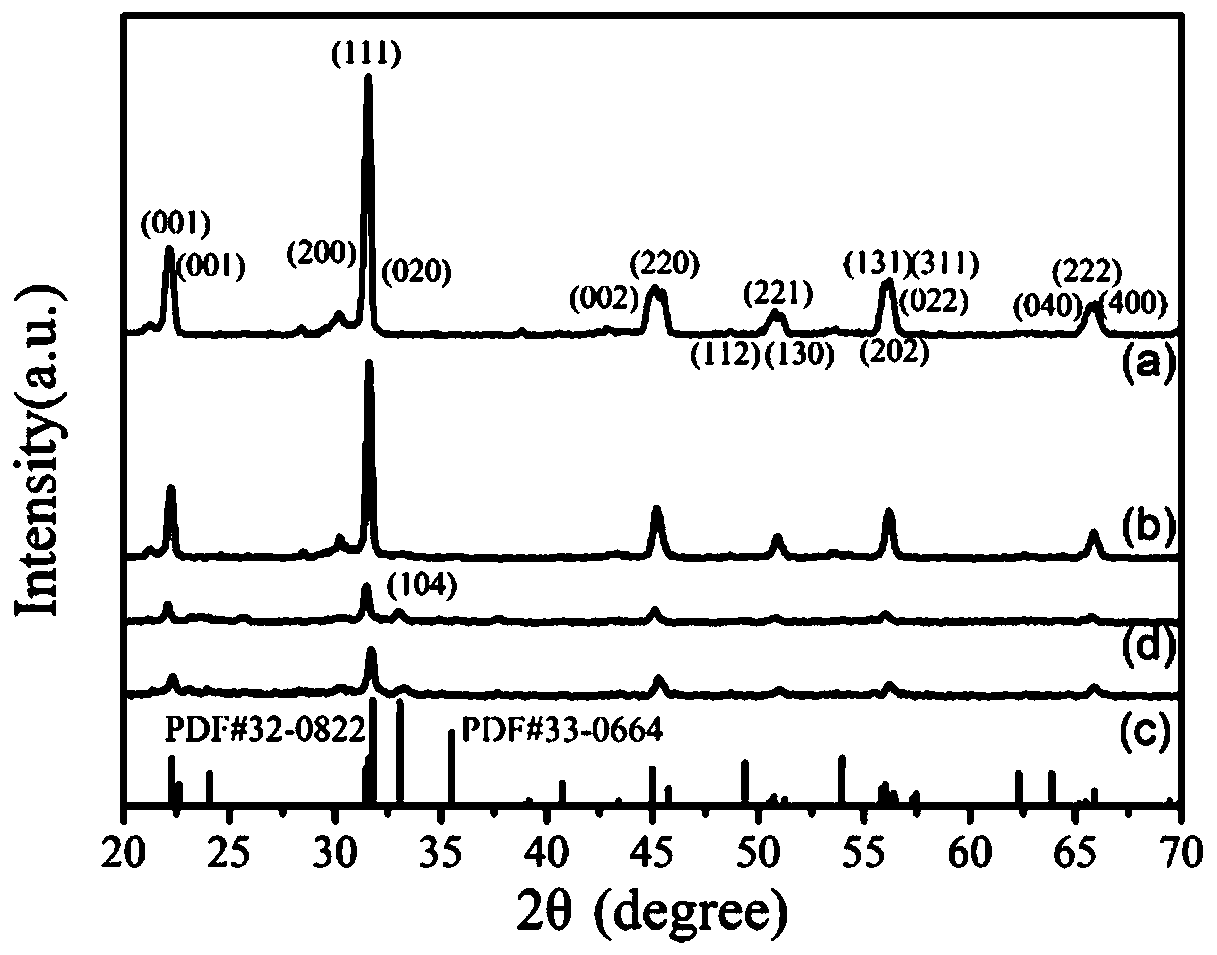

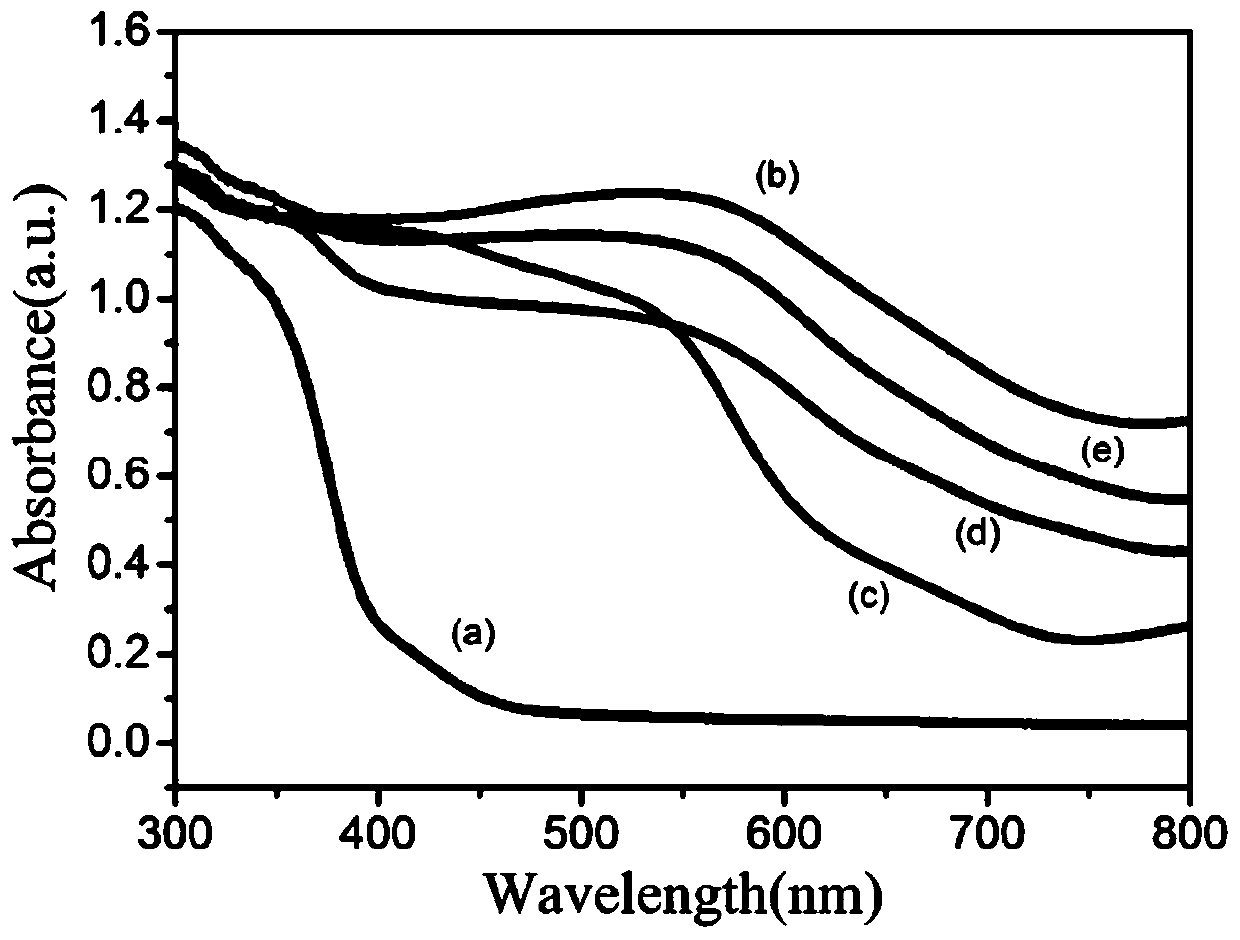

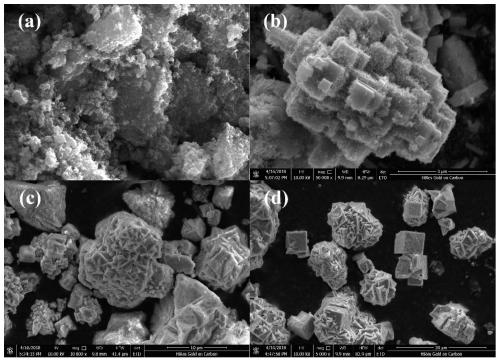

[0025] A kind of KNbO 3 / α-Fe 2 o 3 A method for preparing a heterogeneous photocatalyst, comprising the following steps:

[0026] Step 1: Preparation of KNbO 3: Dissolve 12.624g KOH in 15ml deionized water, then add 0.874g niobium powder, fully stir on a magnetic stirrer for 30min, then transfer to a 50ml polytetrafluoroethylene-lined reactor, and conduct a hydrothermal reaction at 150°C for 12h . The obtained product was fully washed with deionized water until the pH was neutral, and finally baked at 60°C for 12 hours to obtain KNbO 3 Powder;

[0027] Step two: the 0.2g KNbO obtained in step one 3 Powder added to FeCl 3 ·6H 2 O and Na 2 SO 4 25ml of aqueous solution, keep FeCl 3 ·6H 2 O and Na 2 SO 4 The molar ratio is 1:1, while adjusting the FeCl 3 ·6H 2 O and KNbO 3 The molar ratio is 0.4~10:1 to obtain a series of different α-Fe 2 o 3 Mass fraction of heterojunction photocatalyst; add 1.5ml glacial acetic acid to the solution, and stir for 30 minutes; ...

Embodiment 1

[0044] Preparation of KNbO by two-step hydrothermal method 3 / α-Fe 2 o 3 -x, wherein x=0.4, x is FeCl 3 ·6H 2 O and KNbO 3 The mol ratio, concrete steps are as follows:

[0045] Step 1: Preparation of KNbO 3 : Dissolve KOH in deionized water, then add niobium powder, fully stir on a magnetic stirrer, then transfer to a 50ml polytetrafluoroethylene-lined reactor, and conduct a hydrothermal reaction at 150°C for 12h. The obtained product was fully washed with deionized water until the pH was neutral, and finally baked at 60°C for 12 hours to obtain KNbO 3 Powder.

[0046] Step two: the 0.2g KNbO obtained in step one 3 Powder added to FeCl 3 ·6H 2 O and Na 2 SO 4 25ml of deionized water, keep the FeCl 3 ·6H 2 O and Na 2 SO 4 The molar ratio is 1:1, while adjusting the FeCl 3 ·6H 2 O and KNbO 3 The molar ratio of the solution is 0.4:1; add 1.5ml of glacial acetic acid to the solution, and stir for 30 minutes; after stirring evenly, add it to a 50ml polytetrafluo...

Embodiment 2

[0048] Preparation of KNbO by two-step hydrothermal method 3 / α-Fe 2 o 3 -x, where x=2, x is FeCl 3 ·6H 2 O and KNbO 3 The mol ratio, concrete steps are as follows:

[0049] Step 1: Preparation of KNbO 3 : Dissolve KOH in deionized water, then add niobium powder, fully stir on a magnetic stirrer, then transfer to a 50ml polytetrafluoroethylene-lined reactor, and conduct a hydrothermal reaction at 150°C for 12h. The obtained product was fully washed with deionized water until the pH was neutral, and finally baked at 60°C for 12 hours to obtain KNbO 3 Powder.

[0050] Step two: the 0.2g KNbO obtained in step one 3 Powder added to FeCl 3 ·6H 2 O and Na 2 SO 4 25ml of deionized water, keep the FeCl 3 ·6H 2 O and Na 2 SO 4 The molar ratio is 1:1, while adjusting the FeCl 3 ·6H 2 O and KNbO 3 The molar ratio of the solution is 2:1; add 1.5ml of glacial acetic acid to the solution and stir for 30 minutes; after stirring evenly, add it to a 50ml polytetrafluoroethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com