Novel biodiesel solid catalyst KF/Ca-Mg-Al-O as well as preparation method and application thereof

A solid catalyst, biodiesel technology, applied in the direction of physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, catalyst carrier, etc., can solve the problem that the product cannot be effectively separated, the reaction mixture is difficult to separate, and the quality is poor. and other problems, to achieve the effects of abundant raw materials, less loss of alkali dissolution and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

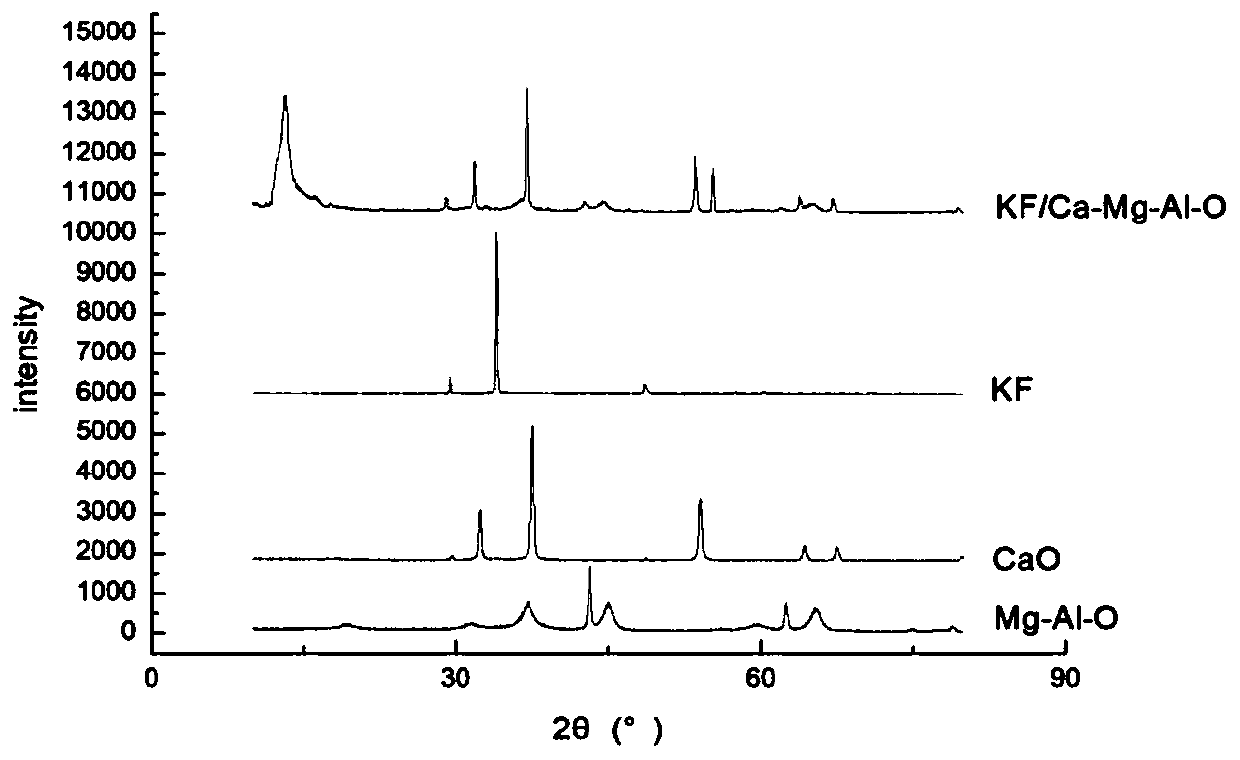

[0043] (1) Mg 2+ and Al 3+ In terms of molar ratio: n(Mg 2+ ):n(Al 3+ )=1:1, take 2.0330g of Mg(Cl) 2 ·6H 2 O and 2.4143g of Al(Cl) 3 ·6H 2 O, dissolved in 300mL deionized water to make solution A; 28% (v / v, ml / ml) ammonia solution was slowly added to solution A while stirring, the stirring speed was 600r / min, to the pH of solution A At 10 o'clock, stop adding the aqueous ammonia solution, let stand, and crystallize at 90°C for 3h, pour the crystallized mixture into a Buchner funnel connected to a suction filter bottle for suction filtration, wash the filter residue with water to pH 7, and dry at 80°C for 6h to obtain Magnesium-aluminum hydrotalcite: Calcining magnesium-aluminum hydrotalcite at a temperature of 700°C for 4 hours to obtain Mg-Al-O.

[0044] (2) Add 2g of Mg-Al-O to 2.1mL of 1wt% Ca(OH) 2 In the solution, immerse at 25° C. for 6 hours, and dry at 80° C. for 6 hours to obtain the modified catalyst carrier precursor Ca-Mg-Al-O. The modified catalyst carri...

Embodiment 2

[0052] (1) Mg 2+ and Al 3+ In terms of molar ratio: n(Mg 2+ ):n(Al 3+ )=3:1, get 6.0990g of Mg(Cl) 2 ·6H 2 O and 2.4143g of Al(Cl) 3 ·6H 2 O, dissolved in 300mL deionized water to make solution A; 28% (v / v, ml / ml) ammonia solution was slowly added to solution A while stirring, the stirring speed was 600r / min, to the pH of solution A At 10.5, stop adding the aqueous ammonia solution, let stand, crystallize at 100°C for 2h, pour the crystallized mixture into a Buchner funnel connected to a suction filter bottle for suction filtration, wash the filter residue to pH 7, and dry at 90°C for 5h to obtain Magnesium-aluminum hydrotalcite: Calcining magnesium-aluminum hydrotalcite at a temperature of 600°C for 5 hours to obtain Mg-Al-O.

[0053] (2) Add 2g of Mg-Al-O to 2.1mL of 3wt% Ca(OH) 2 In the solution, immerse at 22°C for 5h, and dry at 90°C for 5h to obtain the modified catalyst carrier precursor Ca-Mg-Al-O. The modified catalyst carrier precursor Ca-Mg-Al-O was calcine...

Embodiment 3

[0063] (1) Mg 2+ and Al 3+ In terms of molar ratio: n(Mg 2+ ):n(Al 3+ )=5:1, take 10.1650g of Mg(Cl) 2 ·6H 2 O and 2.4143g of Al(Cl) 3 ·6H 2 O, dissolved in 300mL deionized water to make solution A; 28% (v / v, ml / ml) ammonia solution was slowly added to solution A while stirring, the stirring speed was 600r / min, to the pH of solution A At 11:00, stop adding the aqueous ammonia solution, let stand, crystallize at 80°C for 4h, pour the crystallized mixture into a Buchner funnel connected to a suction filter bottle for suction filtration, wash the filter residue with water to pH 7, and dry at 100°C for 4h to obtain Magnesium-aluminum hydrotalcite: Calcining magnesium-aluminum hydrotalcite at a temperature of 900°C for 2 hours to obtain Mg-Al-O.

[0064] (2) Take 2gMg-Al-O and add it to 2.1mL of 5wt% Ca(OH) 2 In the solution, immerse at 20° C. for 4 hours, and dry at 100° C. for 4 hours to obtain the modified catalyst carrier precursor Ca-Mg-Al-O. The modified catalyst car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com