Composite inhibitor for pyrite and easy-to-float gangue in copper-sulfur ore and flotation separation method thereof

A technology of composite inhibitor and separation method, applied in flotation, solid separation, grain treatment, etc., can solve the problems of difficulty in separation of copper and sulfur, affecting the quality of copper concentrate, etc., to reduce adverse effects, strengthen inhibition, and reduce circulation. load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

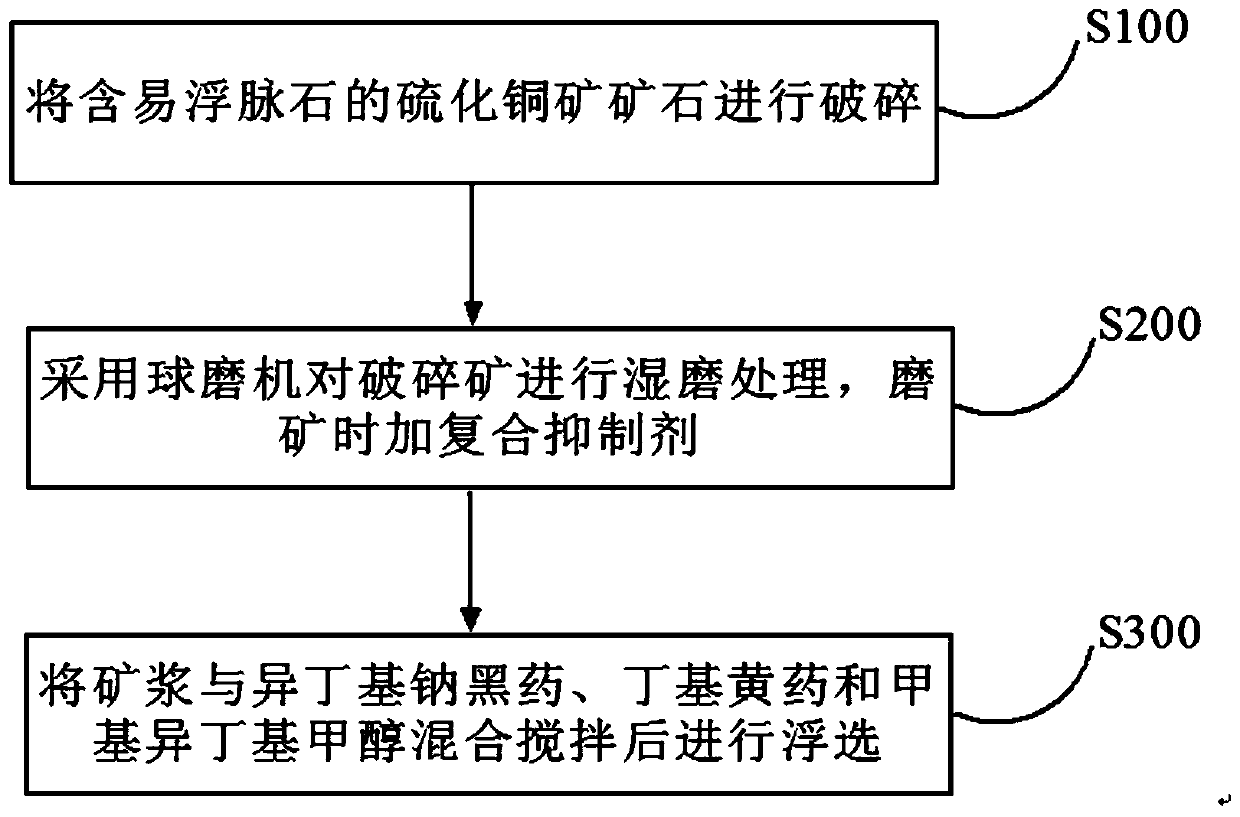

Image

Examples

Embodiment 1

[0037] The raw ore grade is Cu 0.65%, S 5.19%. The mineral composition of the ore is relatively complex, and the metal minerals include chalcocite, chalcopyrite, pyrite, pyrrhotite, limonite and so on. The gangue minerals are mainly quartz, subkaolinite, mica, potash feldspar, chlorite and so on. The intercalation of copper minerals is relatively complex, mostly associated with pyrite and hydrokaolinite, the intercalation particle size is finer, and the dissociation degree of monomer is poor.

[0038] The specific steps of the technological process are:

[0039] 1) Crush and grind the raw ore, so that the useful minerals and gangue minerals in the copper-sulfur ore are fully dissociated, and the ore is ground until the particle size of the copper-sulfur ore is -0.074mm, accounting for 65%; when grinding, add Yu-001 400g / t is used as a pulp pH regulator and inhibitor, adding water to adjust the pulp until the mass concentration of the pulp is 33%, and the pH value of the pul...

Embodiment 1

[0047] The beneficiation indexes of embodiment one and comparative example one are shown in table 1.

[0048] Table 1 Mineral dressing index of embodiment 1 and comparative example 1

[0049] serial number product name Copper concentrate grade, % Copper recovery rate, % pH value of tailings slurry (tailings I and tailings II combined) Embodiment one copper concentrate 32.2 91.0 8.6 Comparative example one copper concentrate 26.5 88.2 10.5

Embodiment 2

[0051] The raw ore grade is Cu 0.88%, S 12.6%. The mineral composition of the ore is relatively complex, and the metal minerals include chalcopyrite, chalcocite, bornite, pyrrhotite, pyrite, marcasite and so on. The gangue minerals are mainly quartz and garnet, followed by talc and serpentine. The intercalation of copper minerals is relatively complex, mostly conjoined with pyrite, pyrrhotite, and quartz. The intercalation particle size is finer and the dissociation degree of monomer is poor.

[0052] The specific steps of the technological process are:

[0053] 1) Crush and grind the raw ore until the copper-sulfur ore particle size -0.074mm accounts for 70%; add Yu-001 500g / t as the slurry pH regulator and inhibitor during the grinding, add water to adjust the slurry until the mass concentration of the slurry is 33%, the pH value of the pulp is 8.0;

[0054] 2) Add 25 g / t of collector butyl sodium black powder to the ore pulp after grinding in step 1, stir for 3 min, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com