Application of Porous Cationic Polymers in Removing Dyes or Heavy Metals from Wastewater

A cationic polymer and heavy metal technology, applied in animal processing wastewater treatment, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of expensive monomers, unfavorable water treatment applications, instability, etc., to achieve Strong modifiability, stable structure, and high charge density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Synthesis of Porous Cationic Polymer PIm-DCX

[0037] 2-Phenylimidazole (PIm) (1 mmol) and α,α'-dichloro-p-xylene (DCX) (1 mmol) in a molar ratio of 1:1 were dissolved in 10 mL of 1,2-dichloroethane solution, Add anhydrous FeCl to the above solution 3 (4 times the molar amount of monomer) (4 mmol), the mixture was stirred and reacted at a temperature of 80° C. for 24 h. After the reaction was completed, it was cooled to room temperature, and the precipitate was collected by filtration and washed with methanol until the washing liquid was clear, and then extracted with methanol for Soxhlet for 24 h. The purified solid product was vacuum-dried at 80 °C for 24 h to obtain a brown powdery solid porous cationic polymer PIm-DCX.

[0038] The structural formula of the porous cationic polymer PIm-DCX is as follows:

[0039]

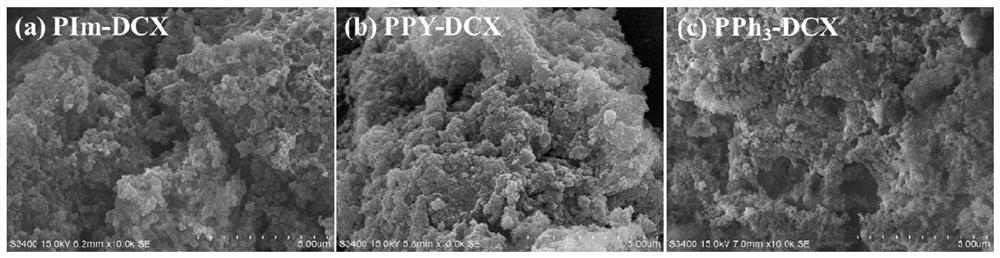

[0040] Scanning electron microscopy of porous cationic polymer PIm-DCX as figure 1 As shown, it is an amorphous structure, which is composed of a l...

Embodiment 2

[0044] Synthesis of Porous Cationic Polymer PIm-BCMB

[0045] 2-phenylimidazole (PIm) (1 mmol) and biphenyl dichlorobenzyl (BCMB) (1 mmol) in a molar ratio of 1:1 were dissolved in 10 mL of 1,2-dichloroethane solution, and to the above solution was added Anhydrous FeCl 3 (4 times the molar amount of monomer) (4 mmol), the mixture was stirred and reacted at a temperature of 90° C. for 22 h. After the reaction was completed, it was cooled to room temperature, and the precipitate was collected by filtration and washed with methanol until the washing liquid was clear, and then extracted with methanol for Soxhlet for 24 h. The purified solid product was vacuum-dried at 80 °C for 24 h to obtain a brown powdery solid porous cationic polymer PIm-BCMB.

[0046] The structural formula of the porous cationic polymer PIm-BCMB is as follows:

[0047]

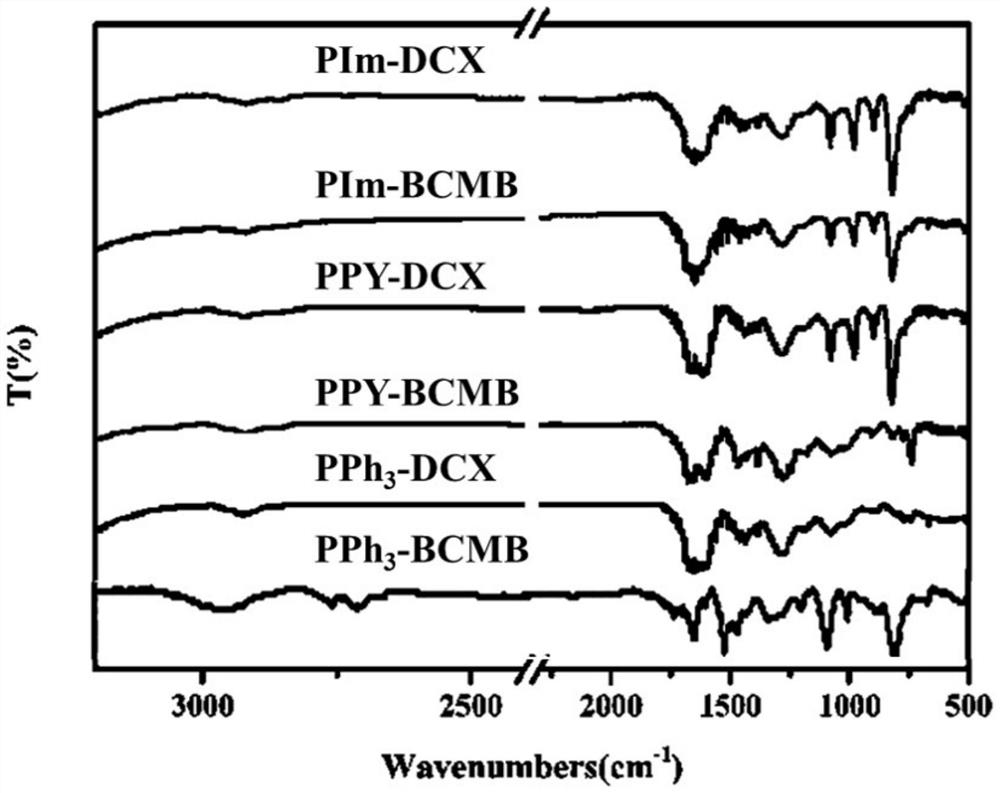

[0048] The infrared spectrum of the porous cationic polymer PIm-BCMB is shown in figure 2 shown at 1656 and 1567cm -1 The two abso...

Embodiment 3

[0051] Synthesis of Porous Cationic Polymer PPY-DCX

[0052] 2-Phenylpyridine (PPY) (1 mmol) and α,α'-dichloro-p-xylene (DCX) (1 mmol) in a molar ratio of 1:1 were dissolved in 10 mL of 1,2-dichloroethane solution, Add anhydrous FeCl to the above solution 3 (4 times the molar amount of monomer) (4 mmol), the mixture was stirred and reacted at a temperature of 80° C. for 24 h. After the reaction was completed, it was cooled to room temperature, and the precipitate was collected by filtration and washed with methanol until the washing liquid was clear, and then extracted with methanol for Soxhlet for 24 h. The purified solid product was vacuum-dried at 80 °C for 24 h to obtain a brown powdery solid porous cationic polymer PPY-DCX.

[0053] The structural formula of the porous cationic polymer PPY-DCX is as follows:

[0054]

[0055] Scanning electron microscopy of porous cationic polymer PPY-DCX as figure 1 As shown, it is an amorphous structure, which is composed of a la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com