Method and device for treating nitrate nitrogen in high-concentration sulfate wastewater

A technology of nitrate nitrogen and treatment method, applied in the field of water treatment, can solve the problems of low denitrification efficiency, easy oxidation of sulfides and high cost, and achieve the effects of strengthening denitrification effect, preventing oxidation and improving removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

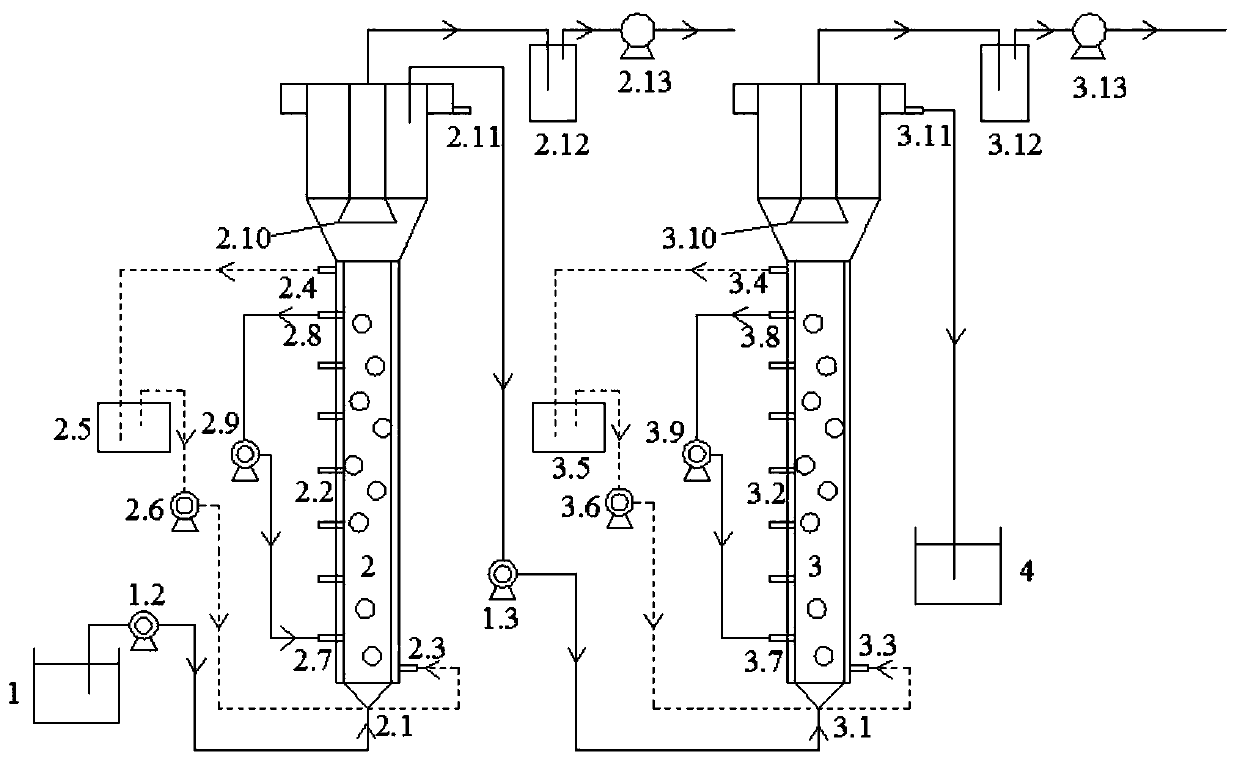

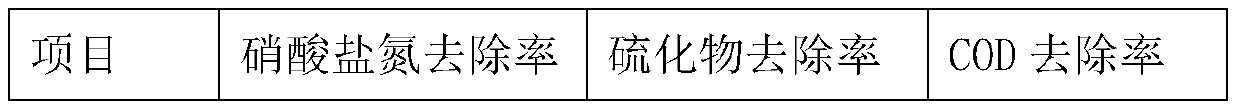

[0047] (1) Inoculate the remaining activated sludge of the secondary settling tank of the urban sewage treatment plant in the reaction zone of the first UASB reactor (2), the sludge accounts for 2 / 3 of the reaction zone volume, and keeps the sludge concentration at 5500mg / L, The filling ratio of the suspension ball filler in the reaction area is 30%; the artificial water with a potassium nitrate concentration of 25 mg / L, a sulfate concentration (prepared with anhydrous sodium sulfate) of 330 mg / L, and a COD / N of 110 is used as the influent. The incoming water enters the first UASB reactor (2) from the incoming water tank (1) through the first water inlet pump (1.2) and the first water inlet (2.1) to carry out the sulfate reduction and denitrification reaction. The ratio of water volume is 28:1, the hydraulic retention time is 22h, sodium bicarbonate is used in the reactor to adjust the pH to 6.5-8.5, and the carbon source is glucose COD Cr The concentration is 2800mg / L, the di...

Embodiment 2

[0051] (1) Inoculate the remaining activated sludge of the secondary settling tank of the urban sewage treatment plant in the reaction zone of the first UASB reactor (2), the sludge accounts for 1 / 3 of the reaction zone volume, and keeps the sludge concentration at 5000mg / L, The filling ratio of the suspension ball filler in the reaction area is 40%; the artificial water with a potassium nitrate concentration of 20mg / L, a sulfate concentration (prepared with anhydrous sodium sulfate) of 300mg / L, and a COD / N of 100 is used as the influent. The incoming water enters the first UASB reactor (2) from the incoming water tank (1) through the first water inlet pump (1.2) and the first water inlet (2.1) to carry out the sulfate reduction and denitrification reaction. The ratio of water volume is 25:1, the hydraulic retention time is 20h, sodium bicarbonate is used in the reactor to adjust the pH to 6.5-8.5, the carbon source is glucose, COD Cr Concentration is 2000mg / L, and dissolved o...

Embodiment 3

[0055] (1) Inoculate the remaining activated sludge of the secondary settling tank of the urban sewage treatment plant in the reaction zone of the first UASB reactor (2), the sludge accounts for 4 / 5 of the reaction zone volume, and keeps the sludge concentration at 6000mg / L, The filling ratio of the suspension ball filler in the reaction area is 20%; the artificial water distribution with a potassium nitrate concentration of 30mg / L, a sulfate concentration (prepared with anhydrous sodium sulfate) of 350mg / L, and a COD / N of 120 is used as the influent. The incoming water enters the first UASB reactor (2) from the incoming water tank (1) through the first water inlet pump (1.2) and the first water inlet (2.1) to carry out the sulfate reduction and denitrification reaction. The ratio of water volume is 30:1, the hydraulic retention time is 24h, sodium bicarbonate is used in the reactor to adjust the pH to 6.5-8.5, the carbon source is glucose, COD Cr Concentration is 3600mg / L, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com