Method for preparing flavonoid compound by separating flos puerariae

A technology of flavonoids and kudzu flower, which is applied in the direction of chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve the problems of time-consuming and laborious separation process, complicated components, and restricted application, so as to achieve low product cost and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The specific operation steps of isolating and preparing a kind of flavonoid compound from Pueraria japonica are as follows:

[0028] (1) Preparation of zirconia

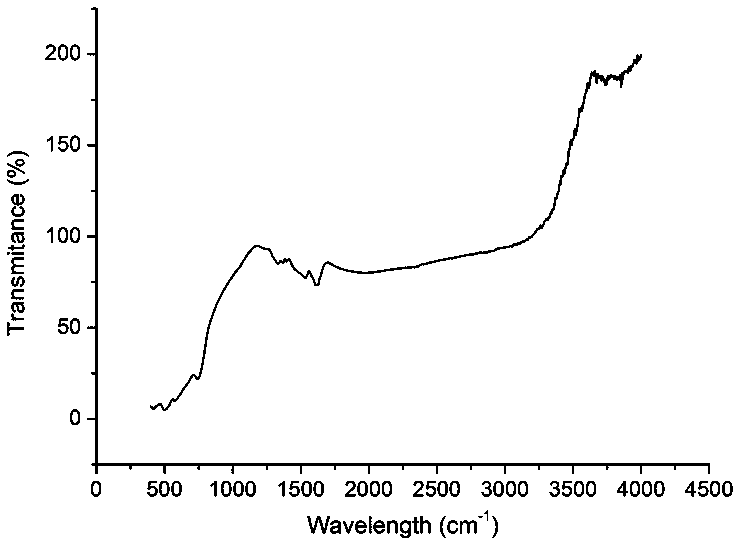

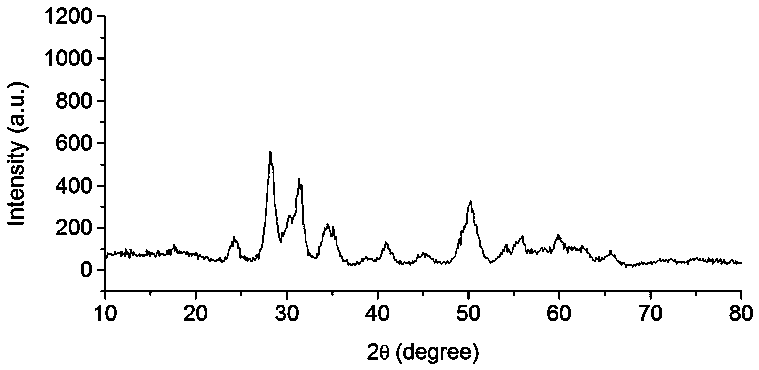

[0029] Zirconium oxychloride (ZrOCl 2 ·8H 2 O) Dissolve in deionized water (0.4 mol / L), slowly add concentrated ammonia water dropwise until the pH value is 10, continue to stir for 1 hour, and obtain a white precipitate; wash with deionized water until pH = 7, and dry in an oven at 110°C ; Calcined at 400°C for 2 hours in a muffle furnace to obtain zirconia. The prepared zirconia was analyzed by infrared spectrometer (Fig. figure 1 shown), its infrared spectrum data (KBr) is: 500-850, 1200-1460, 1460-1680 (cm -1 ); the prepared zirconia was analyzed by X crystal diffractometer (diffraction peaks as attached figure 2 shown), indicating that the prepared zirconia is a mixture of monoclinic and cubic phases.

[0030] (2) Preparation of kudzu flower crude extract

[0031] Fresh kudzu flower was dried at ...

Embodiment 2

[0043] The differences between Example 2 and Example 1 are: (1) During the preparation of zirconia, the concentration of zirconia oxychloride is 0.3mol / L, and the calcination temperature of zirconia is 300°C; (2) The crude extract is prepared The ultrasonic extraction time during the process was 90 minutes; (3) The shaking table oscillation adsorption time during the adsorption process was 6 h; (4) During the desorption process. The concentration of acetic acid is 50%, and the shaking table desorption time is 3h. Other operations and conditions are the same as in Example 1. In Example 2, 6.01 mg of 3'-hydroxyiridin-7-O-β-D-xylosyl-(1→6)-β-D-glucopyranoside was obtained, with a purity of 91% and a yield of 0.55%. .

Embodiment 3

[0045] The differences between Example 3 and Example 1 are: (1) During the preparation of zirconia, the concentration of zirconia oxychloride is 0.5mol / L, and the calcination temperature of zirconia is 200°C; The bed shaking adsorption time is 10 h; (3) The shaking bed desorption time is 9 h during the desorption process. Other operations and conditions are the same as in Example 1. In Example 3, 6.65 mg of 3'-hydroxyiridin-7-O-β-D-xylosyl-(1→6)-β-D-glucopyranoside was obtained, with a purity of 92% and a yield of 0.62%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com