Process device for producing freshly squeezed ancient brown sugar

A process device, brown sugar technology, applied in sucrose production, sugar production, sugar products, etc., can solve the problems of substandard hygiene, unsanitary, destruction of forest resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

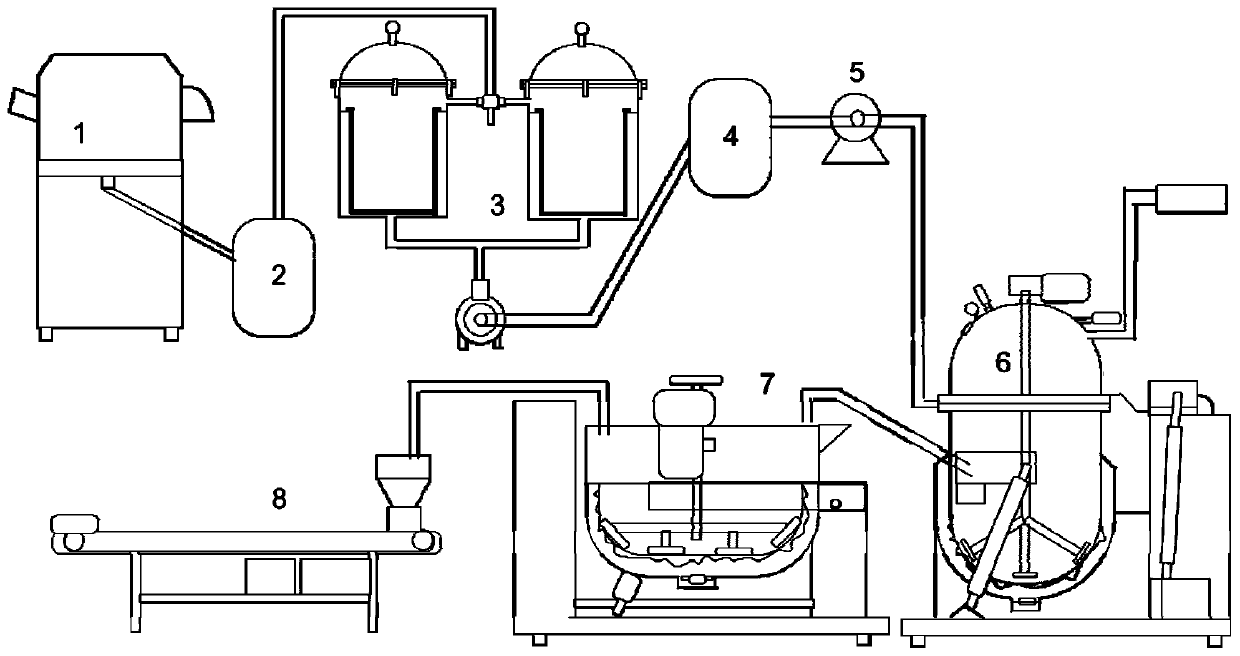

[0095] A process device for freshly squeezed ancient brown sugar production, including a roller press sugarcane press 1, a storage tank 2, a pump filter 3, a buffer tank 4, a delivery pump 5, and a negative pressure electromagnetic dry-wet separator connected in sequence 6. Secondary electromagnetic evaporator 7. Continuous molding machine 8, of which:

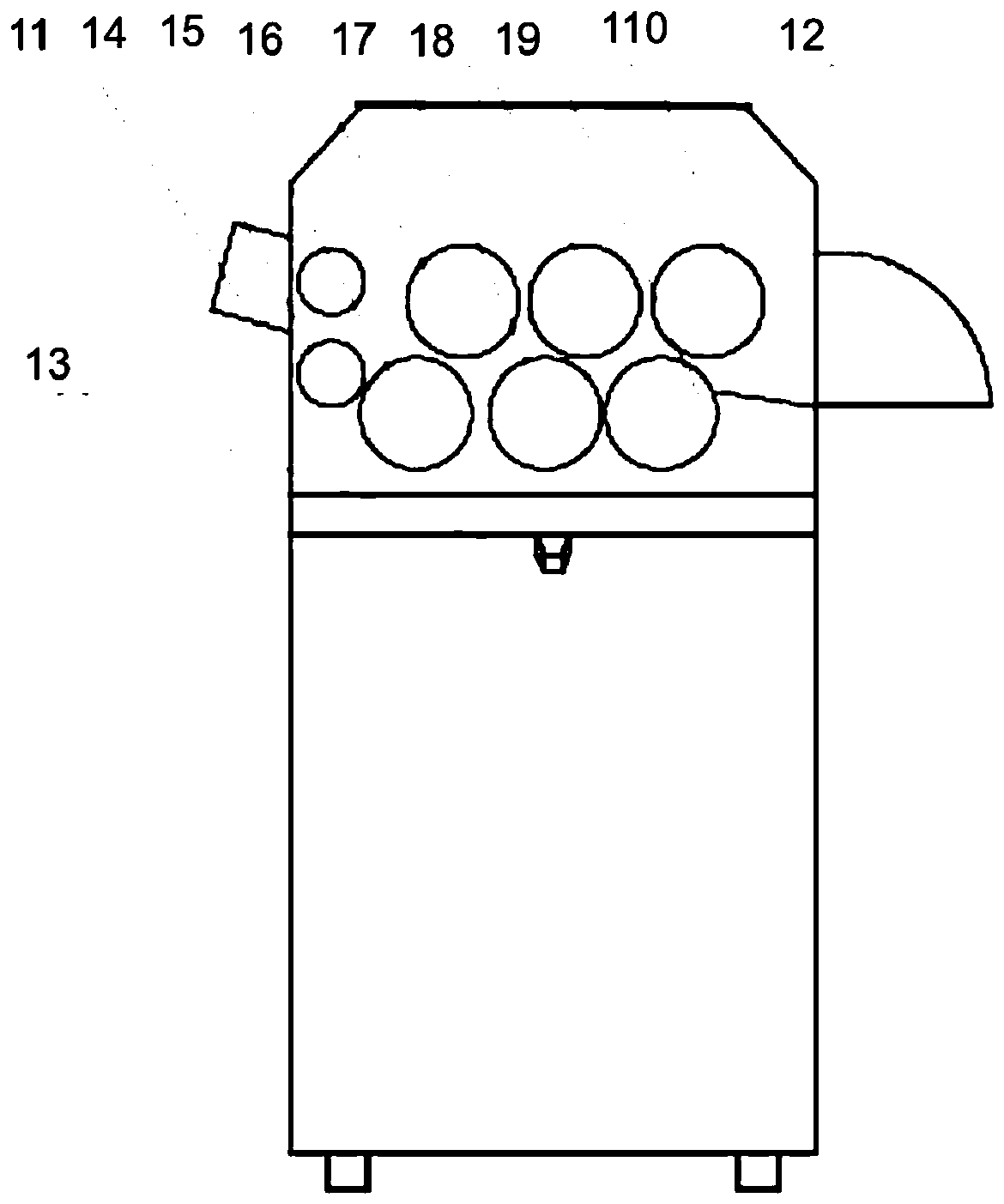

[0096] (1): Roller type sugarcane squeezer 1 is a six-roller sugarcane squeezer, such as figure 2 As shown: there are two auxiliary feed rollers 14 at the front of the press body. The two auxiliary feed rollers are distributed up and down and have a feed gap between them. The feed gap is located behind the feed inlet: the auxiliary feed rollers located below Feeding pressure roller 15 is arranged at the rear and lower part of the upper part, and a skin-breaking pressure roller 16 is arranged at the rear and lower part of the auxiliary feeding roller at the top, and the skin-breaking pressure roller is located at the rear uppe...

Embodiment 2

[0124] Use the processing device in embodiment 1 to carry out the production of freshly squeezed ancient method brown sugar, comprise the following steps:

[0125] (1) Juicing: Put the sugarcane into a disinfection car for routine disinfection, then send the sterilized sugarcane into a sugarcane press for juice extraction, and transport the collected sugarcane juice to a storage tank for later use.

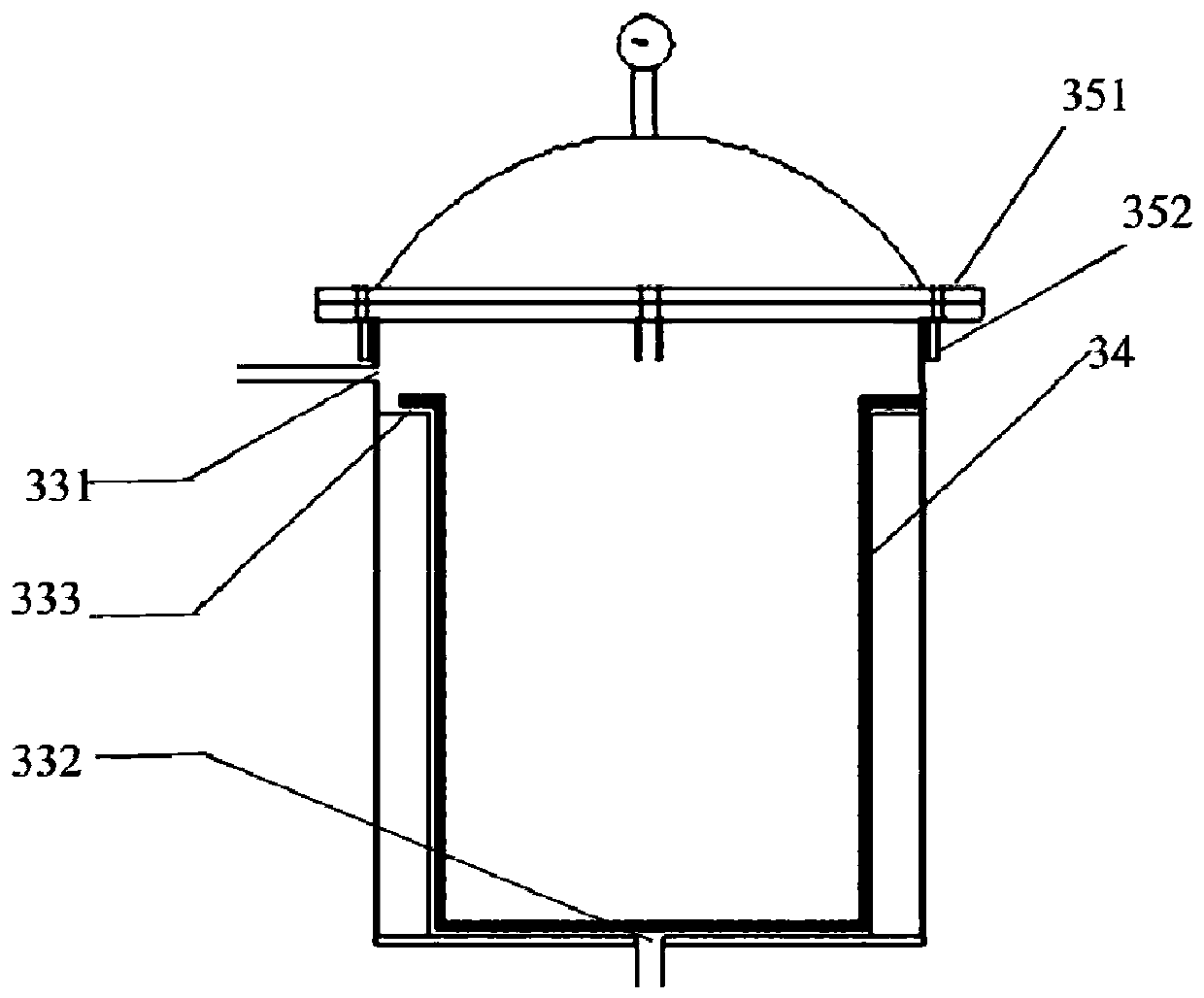

[0126] (2) Filtration: after step (1) finishes, open vacuum pump 1, and vacuum pump 1 produces suction, and under the effect of suction, sugarcane juice in the holding tank is transported to one and / or two airtight pump pressure filtrations through separating valve tank, and carry out negative pressure filtration under the action of the filter screen in it; the impurity-free sugarcane juice obtained after filtration continues to flow out from the outlet of the pump filter tank under the suction of the vacuum pump I, and then pumped by the vacuum pump I Cache in the cache jar;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com