Iron-silicon-aluminum metal powder for 3D printing and preparation method thereof

A metal powder, 3D printing technology, applied in metal processing equipment, transportation and packaging, additive processing, etc., can solve the problem of low resource utilization rate of 3% non-oriented silicon steel waste, achieve good application prospects and good practicability , the effect of good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

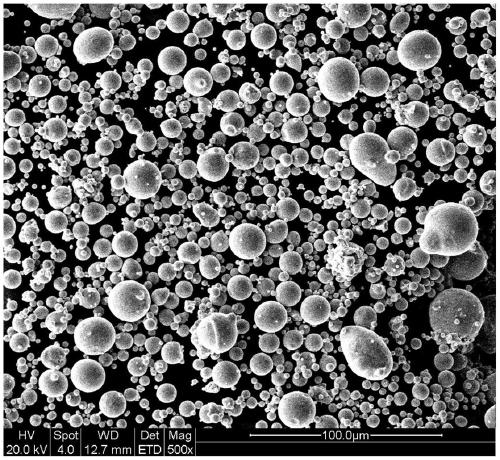

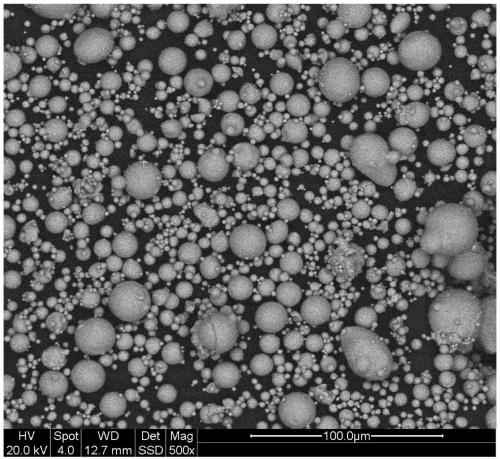

Image

Examples

Embodiment 1

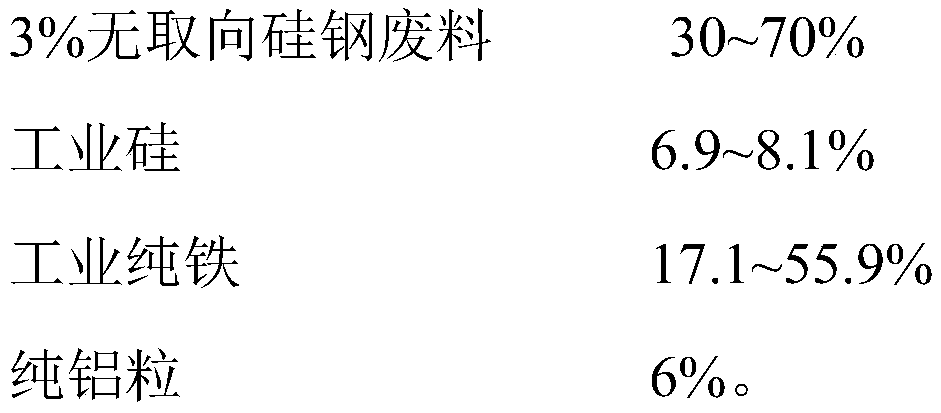

[0030] This embodiment provides a kind of sendust metal powder for 3D printing, which is prepared by the following method:

[0031] (1) Placement of materials in the furnace: 3kg of pure aluminum particles and 3.75kg of granular industrial silicon are mixed and placed on the bottom of the vacuum atomization furnace body, and then 18.25kg of industrial pure iron is placed in the inner and outer rings of the vacuum atomization furnace, and placed Above the aluminum granules and granular industrial silicon, finally place 25kg of 3% non-oriented silicon steel waste in the inner ring surrounded by industrial pure iron;

[0032] (2) Vacuuming treatment: open the vacuum induction melting control device of the vacuum atomization equipment, and pump the vacuum degree in the furnace body of the vacuum atomization furnace to 20Pa;

[0033] (3) Heating and smelting treatment: start to heat up after vacuuming, and the heating process is as follows: 0-30min, the temperature rises to 700°C; ...

Embodiment 2

[0036] This embodiment provides a sendust metal powder, which is prepared by the following method:

[0037] (1) Placement of materials in the furnace: 3.15kg of pure aluminum particles and 3.6kg of granular industrial silicon are mixed and placed at the bottom of the vacuum atomization furnace body, and then 18kg of industrial pure iron is placed in the inner and outer rings of the vacuum atomization furnace, and placed Above the aluminum granules and granular industrial silicon, finally place 25kg of 3% non-oriented silicon steel waste in the inner ring surrounded by industrial pure iron;

[0038] (2) Vacuuming treatment: open the vacuum induction melting control device of the vacuum atomization equipment, and pump the vacuum degree in the furnace body of the vacuum atomization furnace to 20Pa;

[0039](3) Heating and smelting treatment: start to heat up after vacuuming, and the heating process is as follows: 0-30min, the temperature rises to 700°C; 30-40min, 700°C constant t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com