Preparation method of thioether sterically hindered phenol antioxidant

A technology of sterically hindered phenol and antioxidant is applied in the field of preparation of thioether type sterically hindered phenol antioxidant, which can solve the problems of difficulty in realizing industrial application, low conversion rate of effective products, complicated operation process, etc., and achieves easy separation. , the effect of short production cycle and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] For this reason, the present invention provides a kind of preparation method of thioether type hindered phenolic antioxidant, this method selects solid alkali as catalyst, while ensuring product purity, does not need to carry out crystallization purification to reaction mixture, directly cooling can obtain Sulfide-type hindered phenolic antioxidant products, the product yield is significantly improved. The solid base catalyst is easy to separate from the product, reusable and environmentally friendly. The process for synthesizing ethyl 2,2-thiobis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate] has simple operation, significantly reduced production cost and easy industrial application.

[0038] specific:

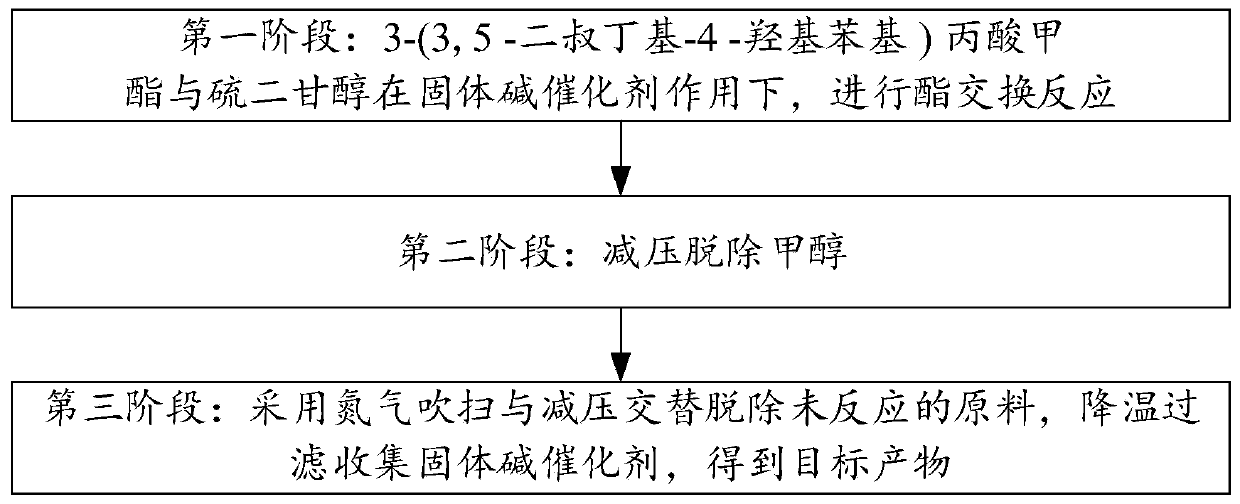

[0039] like figure 1 As shown, the present invention provides a kind of preparation method of sulfide type hindered phenolic antioxidant, comprising:

[0040] Step 1, the first stage: 3-(3,5-di-tert-butyl-4-hydroxyphenyl) methyl propionate and thiodiglycol are sub...

Embodiment 1

[0060] The present invention provides a kind of preparation method of sulfide type hindered phenolic antioxidant, comprising:

[0061] Add 58.98g (0.202mol) 3-(3,5-di-tert-butyl-4-hydroxyphenyl) methyl propionate, 1.18g (2% of the mass of methyl 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate)KOH / Al 2 o 3 Catalyst, replace the air in the reaction system with nitrogen, heat the system to 120 °C, add 12.2 g (0.1 mol) of thiodiglycol in four times, and the time interval between each addition of thiodiglycol is 30 minutes. After feeding, the temperature was raised to 160°C, and the temperature was maintained at 160±5°C for 30 minutes. Turn on the vacuum pump to increase the vacuum degree in the flask (vacuum degree-0.09MPa), keep the reaction for 2 hours, and remove the by-product methanol generated by the reaction. After the reaction, raise the temperature to 170°C, maintain 170±5°C for 30 minutes under reduced pressure, then open the nitrogen valve to purge for 10 minutes, al...

Embodiment 2

[0062] Embodiment 2 (change feed ratio):

[0063] The present invention provides a kind of preparation method of sulfide type hindered phenolic antioxidant, comprising:

[0064] 3-(3,5-di-tert-butyl-4-hydroxyl phenyl) the charging capacity 58.98g (0.202mol) of methyl propionate in embodiment 1 is changed into 61.32g (0.21mol), all the other parts and embodiment 1 remained the same, and the product 2 was obtained in 99.5% yield and 96.7% purity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com