Grating manufacturing process for adhering heavy metal colloid to light metal film

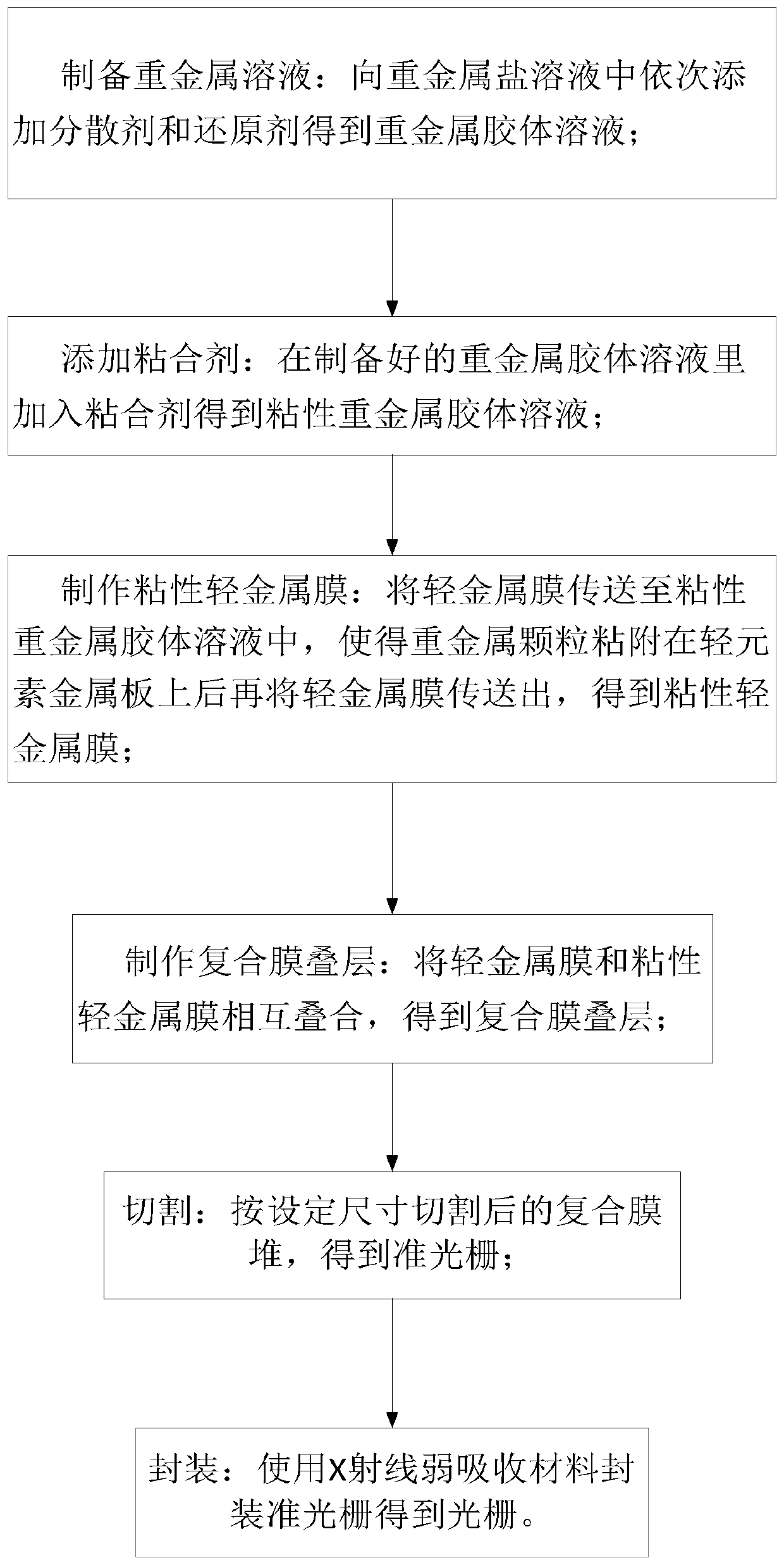

A production process and heavy metal technology, applied in the direction of diffraction grating, metal layered products, optics, etc., can solve the problems of high production cost, great influence of etching structure, complex process of photo-assisted electrochemical etching method, etc., and reach the production cycle Short, low cost and low price, convenient and fast production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Dissolve 30g of silver nitrate in 150mL of distilled water and 30mL of concentrated ammonia water to prepare a silver-ammonia complex solution; then dissolve 7.5g of lauric acid in 1000mL of distilled water and 75 mL of concentrated ammonia water to prepare an aqueous solution of lauric acid; turn on electric stirring The device mixes the silver ammonia solution and the lauric acid aqueous solution evenly, and controls the stirring speed at 800-1000 r / min. At room temperature, add NaBH4 solution dropwise to the above mixed solution, the molar ratio of reducing agent NaBH4 to silver nitrate is [AgNO3] / [NaBH4] = 4, and then stir for 1 h after the addition is completed, the black nano-silver Colloid; when it is necessary to prepare a large amount of nano-silver colloid, the amount of reagent can be increased in equal proportion.

[0057] In the present embodiment, when adding adhesive, adhesive is heating volatile adhesive; Adhesive includes bisphenol A type, novolac creso...

Embodiment 2

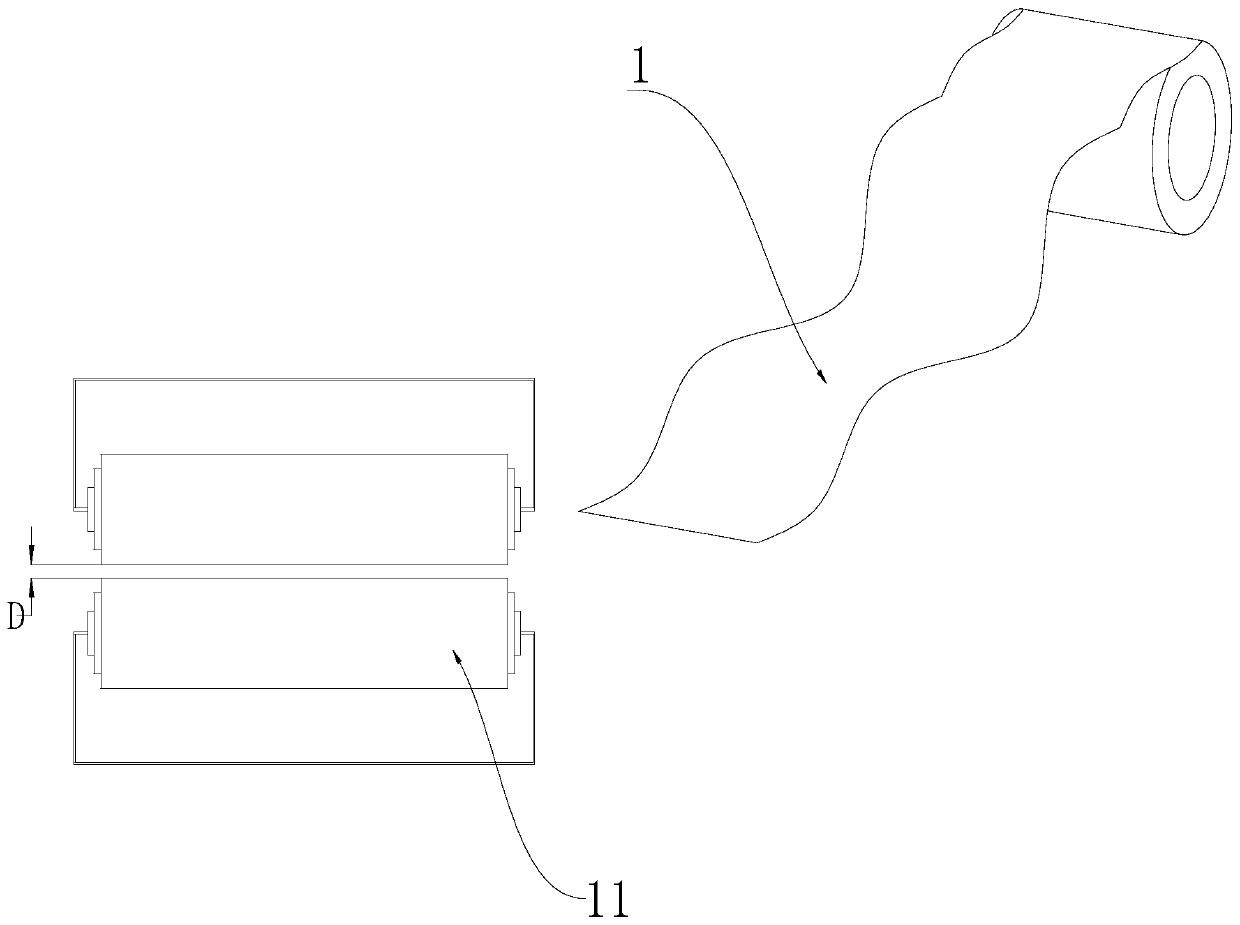

[0066] The sticky light metal film 1 is a long strip that has not been broken. The light metal film 1 is pre-cut into a piece of light metal film with a set shape and size, such as a light metal module with a length of 10 cm, a width of 6 cm, and a thickness of 30 microns; The width of the light metal is 6 cm, the thickness is 30 microns, and the thickness of the heavy metal layer 2 on the sticky light metal is 50 microns; the light metal film 1 is used as the bottom layer, and a layer of sticky light metal film 1 is covered on the light metal film 1, and then on the sticky light metal film 1 Stacking light metal films 1, stacking alternately to form a consistent film stack, the period of the grating 7 is 80 microns; among them, the alternate stacking adopts the zigzag stacking method, and the stacking efficiency is high; the opposite sides of the composite film stack will produce bending due to the sticky metal film resulting connection 13.

Embodiment 3

[0068] Both the light metal film 1 and the sticky light metal film 1 are broken into a metal film block of a set size, and one piece of light metal film is cut into one piece of light metal film with a set shape and size after passing through the rolling equipment, for example, the cut length is 10cm , an adhesive light metal module with a width of 6 cm and a thickness of 30 microns, the thickness of the heavy metal layer 2 on the adhesive light metal is 50 microns; the size of the light metal film 1 is exactly the same as that of the adhesive light metal; directly place the light metal film 1 and the adhesive metal module Stacked alternately to form a composite film stack; the period of the 7 gratings is 80 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com