Preparation method of zirconium dioxide microspheres

A zirconia and microsphere technology, applied in zirconia and other directions, can solve the problems of poor particle size uniformity and poor size controllability of zirconia microspheres, and achieve the effect of uniform particle size and controllable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The embodiment of the present invention provides a preparation method of zirconia microspheres, comprising:

[0023] adding the seed microspheres into the aqueous solution containing the dispersant, fully stirring to form a uniformly dispersed seed mixture, the seed microspheres accounting for less than 60% of the weight of the seed suspension;

[0024] Mix the initiator and dispersant evenly to obtain an initiator solution;

[0025] Mix zirconium n-propoxide, alcohol solvent and ammonia water evenly to obtain a precursor mixture;

[0026] Under ultrasonic conditions, the initiator solution is first dropped into the seed mixed solution, and then the precursor mixed solution is added dropwise to react to obtain polymer / zirconia composite microspheres;

[0027] vacuum drying the polymer / zirconia microspheres;

[0028] The dried polymer / zirconia microspheres are heated step by step, the polymer is removed, and finally the zirconia microspheres are obtained.

[0029] In ...

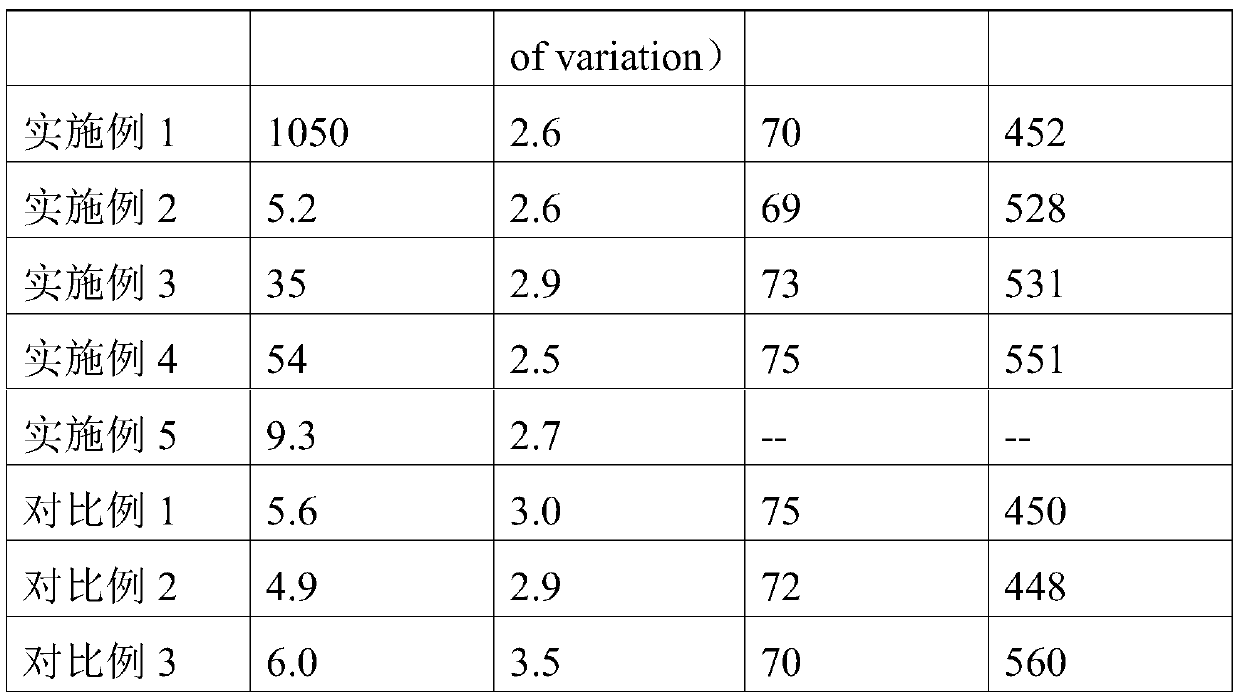

Embodiment 1

[0040] Add styrene-divinylbenzene copolymer seed microspheres (particle size 855 μm, CV=3%) into the aqueous solution containing dextrin, stir well to form a uniformly dispersed seed mixture, styrene-divinylbenzene copolymer The seed microspheres account for 45% of the seed suspension weight; the dextrin weight is 8% of the seed microspheres weight; the benzoyl peroxide is added into the aqueous solution containing polyvinylpyrrolidone and then emulsified to form an initiator solution for subsequent use; Ionized water, 400mL of isopropanol, 5mL of 28% ammonia water and 50mL of ethanol solution containing 10% n-propoxide zirconium were mixed and ultrasonicated for 2 hours to obtain a precursor mixture.

[0041] At 70°C, add the initiator solution dropwise into the seed mixture within 60 minutes to grow the seed microspheres, and stop adding the initiator solution after reaching the preset microsphere particle size. Then the precursor mixed solution is added dropwise to react to...

Embodiment 2

[0044] Add styrene-divinylbenzene copolymer seed microspheres (particle size 0.5 μm, CV=2.8%) into the aqueous solution containing dextrin, stir well to form a uniformly dispersed seed suspension, and styrene-divinylbenzene copolymerization The seed microspheres account for 52% of the seed suspension weight; the dextrin weight is 8% of the seed microsphere weight; benzoyl peroxide is added to the aqueous solution containing polyvinylpyrrolidone and then emulsified to form an initiator solution for subsequent use; 40mL Deionized water, 400 mL of isopropanol, 5 mL of 28% ammonia water and 50 mL of ethanol solution containing 10% n-propoxide zirconium were mixed and then ultrasonicated for 2 hours to obtain a precursor mixed solution.

[0045] At 70°C, the mixed porogen and initiator solution of polyethylene glycol, urea and ammonium sulfate with potassium chloride and sodium chloride was added to the seed suspension to grow the seed microspheres within 60 minutes to reach the pre...

PUM

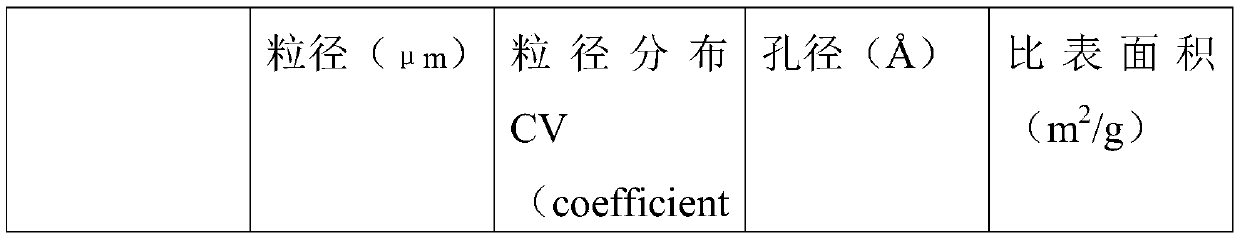

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com