Virus-killing waterproof breathable film and preparation method thereof

A waterproof and breathable membrane and virus killing technology, applied in separation methods, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problem that medical masks or protective clothing are not ideal for sterilization, increase respiratory burden and work. The pressure, the inability to kill super bacteria and viruses, etc., achieve the effect of simple and controllable production process, convenient large-scale production, and guaranteed quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

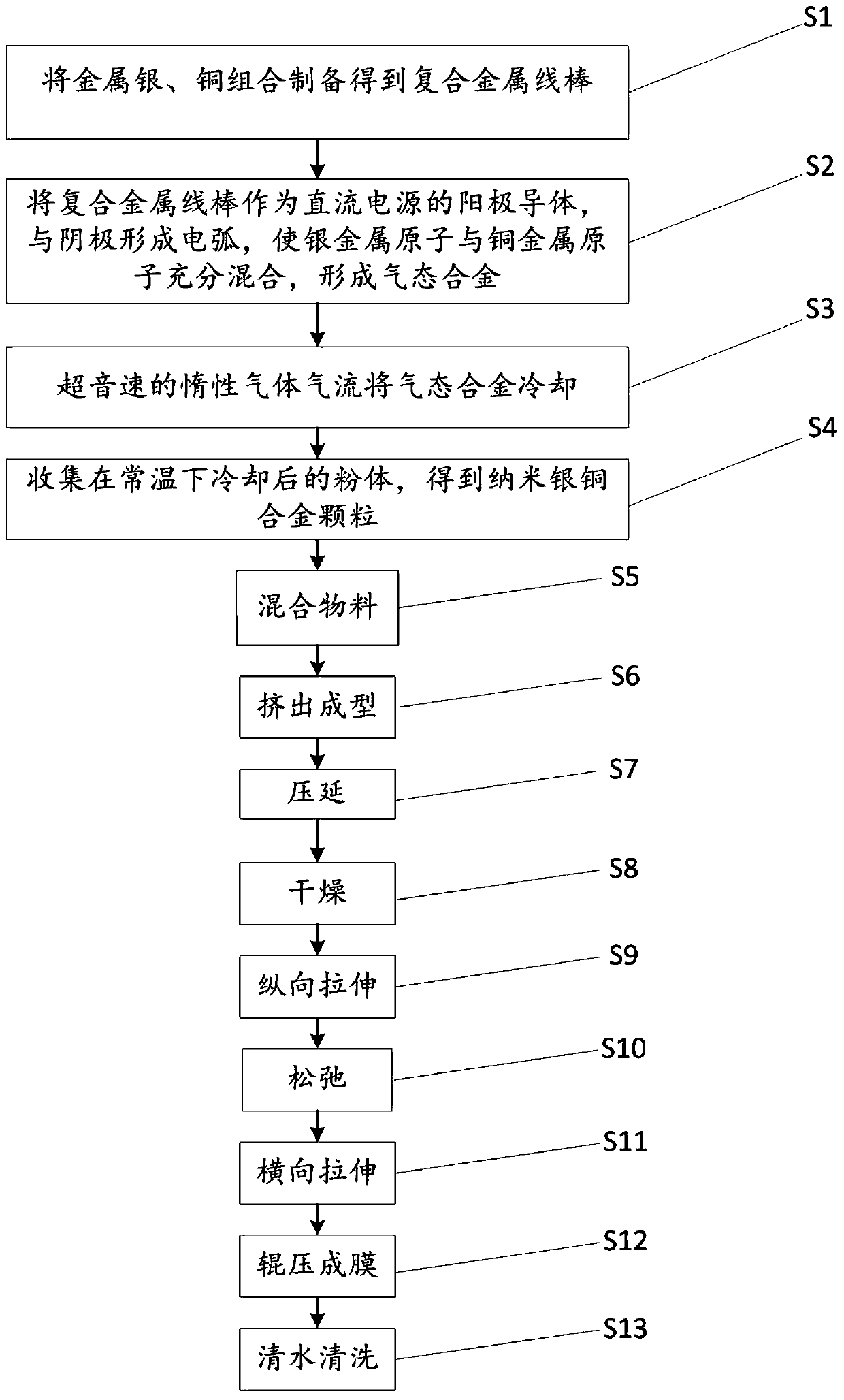

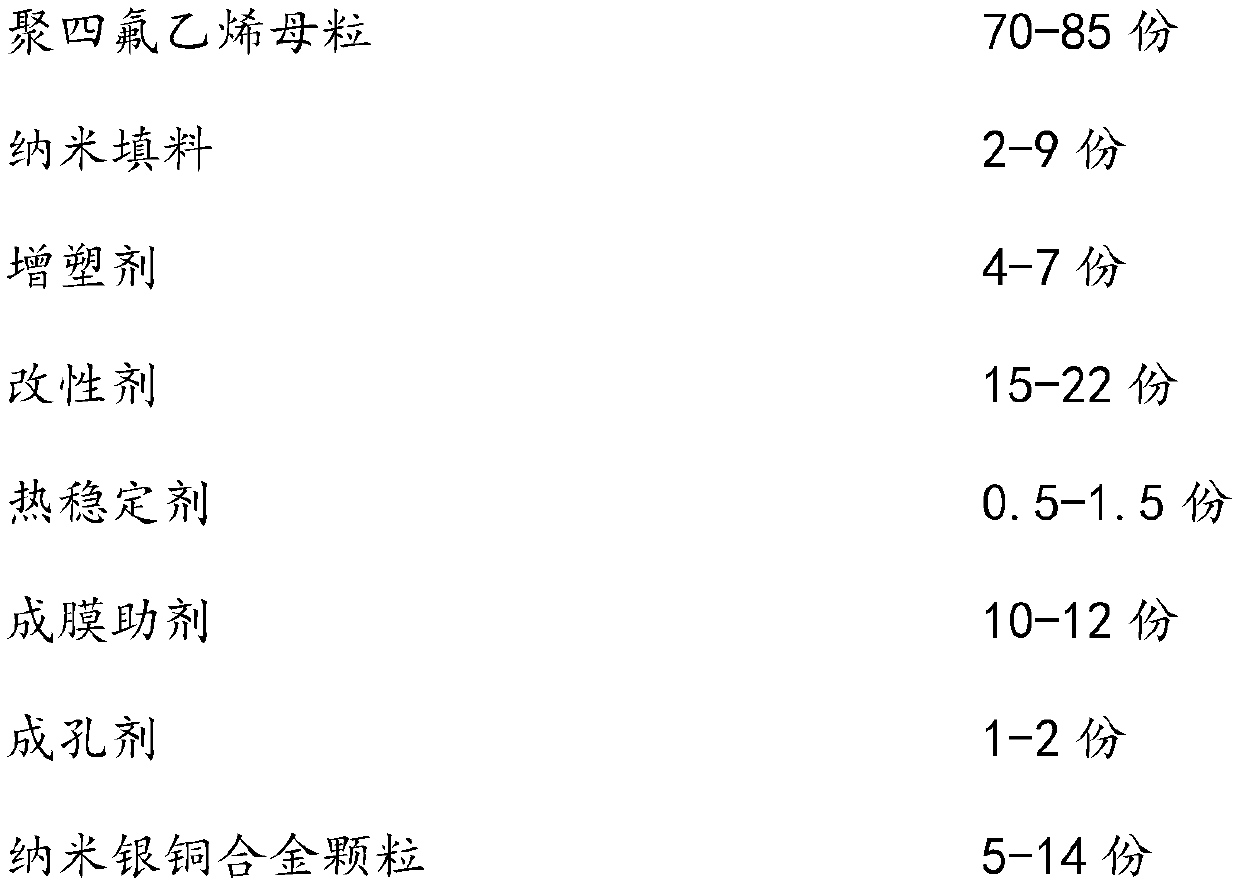

[0054] On the other hand, the present invention also provides a method for preparing a waterproof and breathable membrane, comprising the following steps:

[0055] S1. Combining metal silver and copper to prepare a composite metal wire rod, wherein, by weight percentage, silver is 40% to 80%, and the rest is copper;

[0056] S2. Use the composite metal wire rod as the anode conductor of the DC power supply, and form an arc with the cathode, so that the tip of the metal wire rod of the anode conductor is vaporized and evaporated to produce smoky metal atom clusters, and the silver metal atoms and copper metal atoms are fully mixed to form a gaseous state alloy, wherein the temperature of the arc formed between the anode conductor and the cathode is 5000-6000°C;

[0057] S3. While the metal is vaporized, the gaseous alloy is cooled by an inert gas flow at 1 to 1.4 times the supersonic speed;

[0058] S4. Collect the powder after cooling at normal temperature to obtain silver-co...

Embodiment 1

[0070] A method for preparing a virus-killing poly waterproof breathable membrane material, comprising the following steps:

[0071] S1. Combining metal silver and copper to prepare a composite metal wire rod, wherein, by weight percentage, silver accounts for 40% and copper accounts for 60%;

[0072] S2. Use the composite metal wire rod as the anode conductor of the DC power supply, and form an arc with the cathode, so that the tip of the metal wire rod of the anode conductor is vaporized and evaporated to produce smoky metal atom clusters, and the silver metal atoms and copper metal atoms are fully mixed to form a gaseous state alloy, wherein the temperature of the arc formed by the anode conductor and the cathode is 5000°C;

[0073] S3. With metal vaporization, the gaseous alloy is cooled by a 1.4 times supersonic inert gas flow;

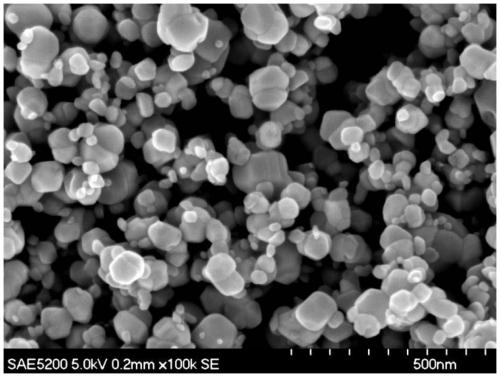

[0074] S4. Collect the powder after cooling at normal temperature to obtain nano-silver-copper alloy particles with a particle size of 15nm to ...

Embodiment 2

[0085] A method for preparing a virus-killing poly waterproof breathable membrane material, comprising the following steps:

[0086] S1. Combining metal silver and copper to prepare a composite metal wire rod, wherein, by weight percentage, silver accounts for 80% and copper accounts for 20%;

[0087]S2. Use the composite metal wire rod as the anode conductor of the DC power supply, and form an arc with the cathode, so that the tip of the metal wire rod of the anode conductor is vaporized and evaporated to produce smoky metal atom clusters, and the silver metal atoms and copper metal atoms are fully mixed to form a gaseous state alloy, wherein the temperature of the arc formed between the anode conductor and the cathode is 6000°C;

[0088] S3. With metal vaporization, the gaseous alloy is cooled by an inert gas flow at 1 times the supersonic speed;

[0089] S4. Collect the powder after cooling at normal temperature to obtain nano-silver-copper alloy particles with a particle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com