High-performance self-cleaning organic silicon coating composition and preparation method thereof

A silicone coating, high-performance technology, applied in the field of coatings, can solve the problems of loss of mechanical properties, damage, biodegradation, and poor heat and aging resistance, and achieve improved biodegradation resistance, heat and aging resistance, and materials The surface is smooth and uniform, and the effect of broadening the antibacterial spectrum band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

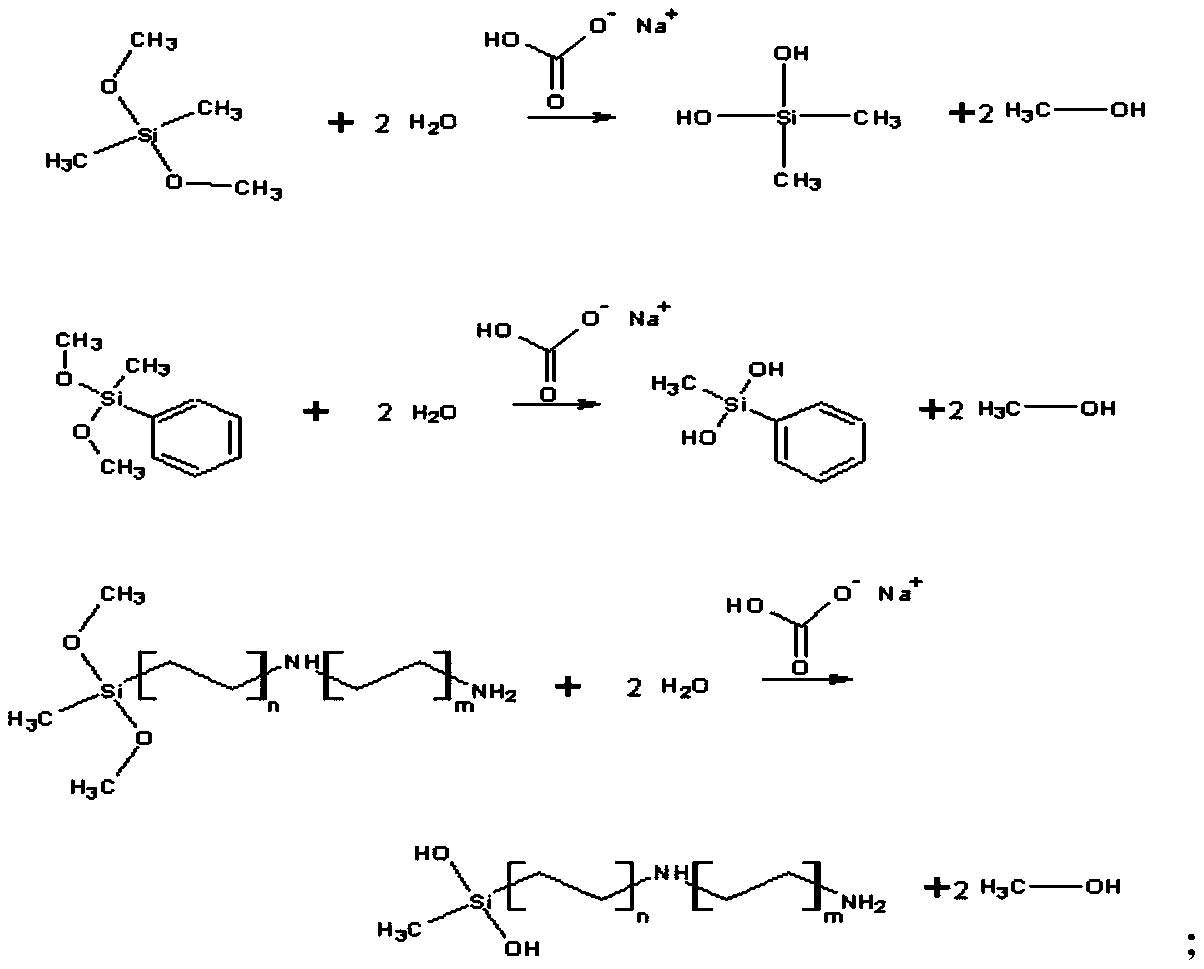

Method used

Image

Examples

Embodiment 1

[0040] (1) Preparation of silicone resin emulsion

[0041] Capped multi-purpose adjustable antibacterial silicone resin 45 parts, complex emulsifier: 2.5 parts, deionized water: 52.5 parts.

[0042] Among them: end-capped multi-purpose adjustable antibacterial silicone resin is Where a is 4; b is 1; c is 6; n is 1; m is 1.

[0043] Composite emulsifier: cetyl ammonium bromide, octadecyl ammonium bromide, nonylphenol polyoxyethylene ether (EO=15-20), octylphenol polyoxyethylene ether (EO=15-20 ) of one or more mixtures.

[0044] Process:

[0045] Weigh and add deionized water into the dispersion container, heat to 45-50°C, add compound emulsifier, stir and disperse for 5 minutes at a stirring speed of 300 rpm, weigh the end-capped multi-purpose adjustable antibacterial silicone resin And heated to 45-50°C, then slowly added to the dispersion container, stirred and dispersed for 10 minutes at a stirring speed of 500 rpm, cooled to room temperature, and obtained.

[0046] (...

Embodiment 2-6

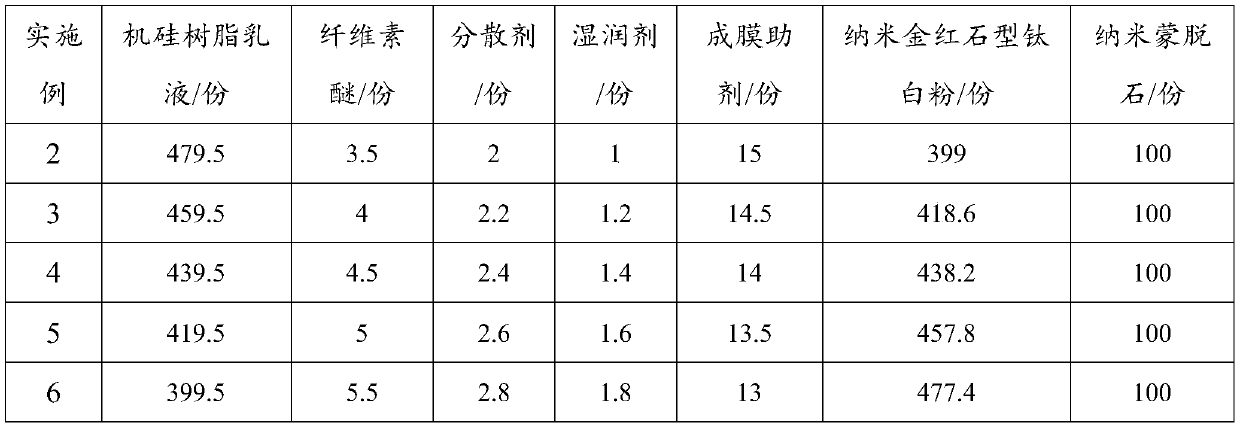

[0053] Compared with Example 1, Examples 2-6 are different except for the content of each component of silicone resin emulsion, cellulose ether, dispersant, wetting agent, film-forming aid, nano-rutile titanium dioxide, and nano-montmorillonite , all the other are the same as embodiment 1.

[0054] The content table of each component of table 1 embodiment 2-6

[0055]

Embodiment 7-12

[0057] Examples 7-12 are the same as Example 1 except that the end-capped multi-purpose adjustable antibacterial silicone resin is different from Example 1. The structure of the end-capped multipurpose adjustable antibacterial silicone resin is Wherein a is 1-10; b is 1-2; c is 1-10; n is 1, 2 or 3; m is 1, 2 or 3.

[0058] The specific values of a, b, c, n and m in the multi-purpose adjustable antibacterial silicone resin of table 2 embodiment 7-12

[0059] Example a b c n m 7 4 1 6 2 2 8 4 2 6 3 2 9 3 1 7 2 2 10 6 1 4 2 2 11 6 1 4 3 2 12 6 2 4 2 2

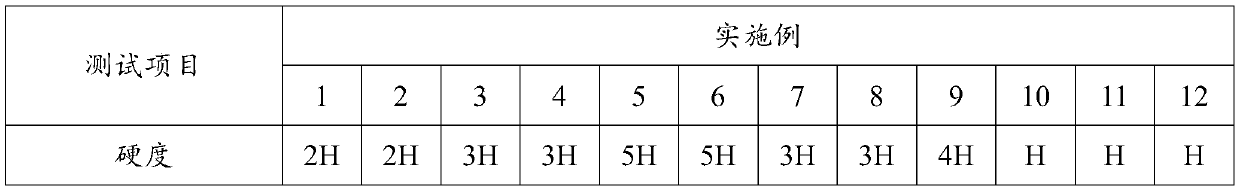

[0060] Experimental part

[0061] Note: Hardness is tested according to GB / T 6739-2006; antibacterial rate is tested according to GB / T21866-2008; xenon lamp aging is tested according to GB / T16422.2-2014 / ISO 4892-2:2006; UV lamp aging (with or without yellowing) According to GB / T16422.3-2014 / ISO 4892-3:2006 test; the evaluation of stain resistance in sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com