Novel three-dimensional silicon structure supercapacitor electrode material and preparation method thereof

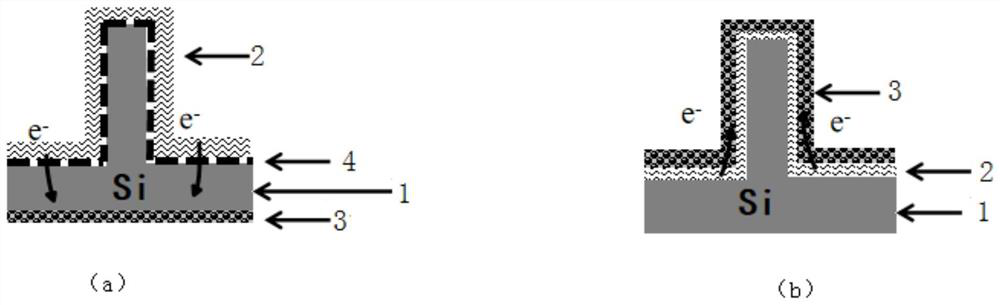

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of complex preparation steps, complex processes, and high manufacturing costs, and achieve increased collection efficiency and low equivalent internal resistance. , the effect of high specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

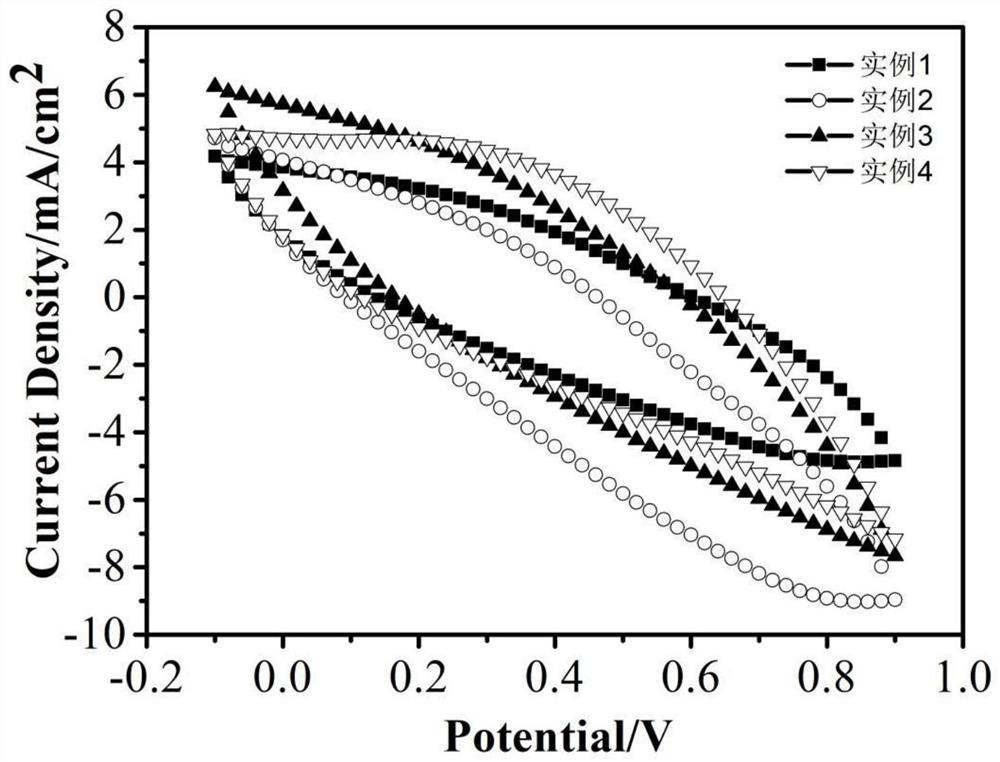

Embodiment 1

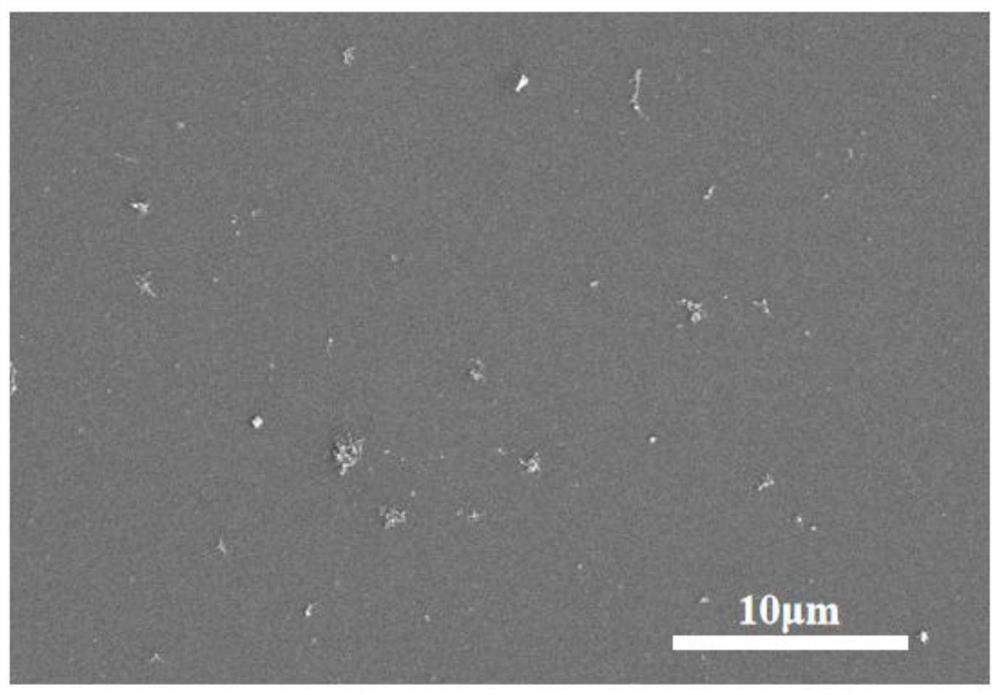

[0029] (1) Silicon nanowires (SiNWs) were prepared by solution etching, and treated twice to prepare a silicon substrate with a three-dimensional surface structure.

[0030] (a) Select N-type (100 crystal orientation), single-sided polished silicon wafer with a resistivity of 5-7Ω cm, cut into 1cm*2cm samples, wash with ethanol and deionized water for many times; Put it into the etching solution containing 5mol / L and 0.02mol / L silver nitrate and etch for 60min.

[0031] (b) Soak the silicon wafer in a concentrated nitric acid solution for more than 1 hour to remove the residual silver particles on the surface of the silicon nanowires, then fully wash it with deionized water, and dry it at a high speed with a homogenizer.

[0032] (c) The silicon wafer is immersed in a chlorobenzene saturated solution of phosphorus pentachloride for secondary treatment. The treatment time is 3 hours, and the treatment temperature is 120° C.

[0033] (2) Spin-coat 3 layers of PEDOT:PSS solution...

Embodiment 2

[0037] (1) Silicon nanowires (SiNWs) were prepared by solution etching, and treated twice to prepare a silicon substrate with a three-dimensional surface structure.

[0038] (a) Select N-type (100 crystal orientation), single-sided polished silicon wafer with a resistivity of 5-7Ω cm, cut into 1cm*2cm samples, wash with ethanol and deionized water for many times; Put it into the etching solution containing 5mol / L and 0.02mol / L silver nitrate and etch for 60min.

[0039] (b) Soak the silicon wafer in a concentrated nitric acid solution for more than 1 hour to remove the residual silver particles on the surface of the silicon nanowires, then fully wash it with deionized water, and dry it at a high speed with a homogenizer.

[0040] (c) The silicon wafer is immersed in a chlorobenzene saturated solution of phosphorus pentachloride for secondary treatment. The treatment time is 3 hours, and the treatment temperature is 120° C.

[0041] (2) Spin-coat 3 layers of PEDOT:PSS solution...

Embodiment 3

[0047] (1) Silicon nanowires (SiNWs) were prepared by solution etching, and treated twice to prepare a silicon substrate with a three-dimensional surface structure.

[0048] (a) N-type (100 crystal orientation), single-sided polished silicon wafer with a resistivity of 5-7Ω·cm, cut into 1cm*2cm samples, washed with ethanol and deionized water for many times; at room temperature and pressure Put it into the etching solution containing 5mol / L and 0.02mol / L silver nitrate and etch for 60min.

[0049] (b) Soak the silicon wafer in a concentrated nitric acid solution for more than 1 hour to remove the residual silver particles on the surface of the silicon nanowires, then fully wash it with deionized water, and dry it at a high speed with a homogenizer.

[0050] (c) The silicon wafer is immersed in a chlorobenzene saturated solution of phosphorus pentachloride for secondary treatment. The treatment time is 3 hours, and the treatment temperature is 120° C.

[0051] (2) Spin-coat 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com