Perovskite solar cell based on composite hole transport layer and preparation method thereof

A technology of hole transport layer and perovskite, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of slow extraction speed, low mobility, and poor energy level matching, so as to improve the interface, Effect of improving electrical conductivity and improving energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Further, a method for preparing a composite hole transport layer is provided, comprising the following steps:

[0038] Step 1: Coating the aqueous solution of PEDOT:PSS on the substrate, forming the PEDOT:PSS layer 31 after annealing, the weight ratio of PEDOT and PSS in the aqueous solution of PEDOT:PSS is 1:2~1:8, preferably 1:6;

[0039] Step 2: coating the amphiphilic molecule solution on the PEDOT:PSS layer 31 to form a hole modification layer 32, the solute concentration in the amphiphilic molecule solution is 0.1mg / ml~1mg / ml, preferably The concentration is 0.25mg / ml-0.75mg / ml.

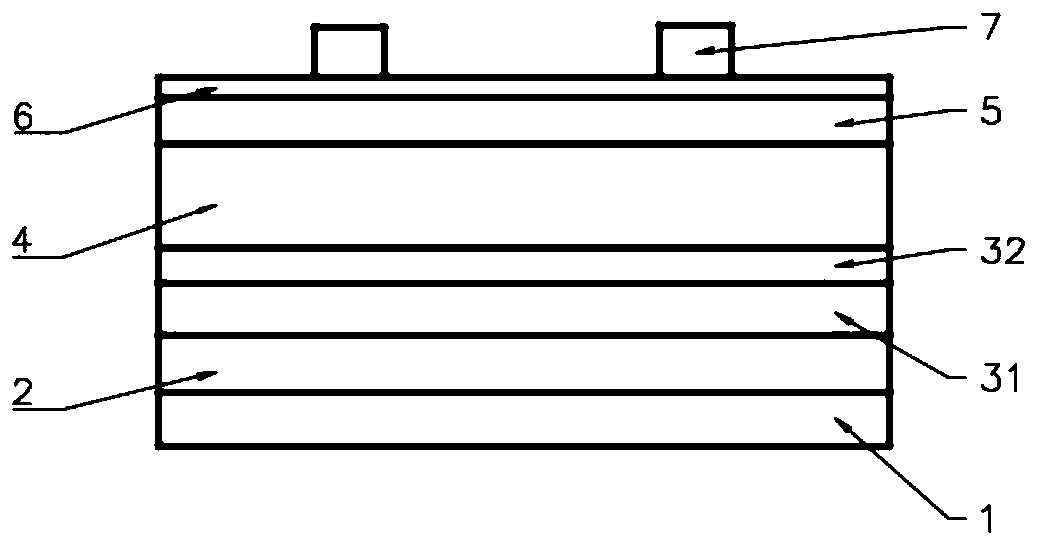

[0040] further, figure 1 A perovskite solar cell based on a composite hole transport layer is provided, which sequentially includes a transparent substrate 1, a transparent electrode 2, a composite hole transport layer, a perovskite active layer 4, an electron transport layer 5, a hole Barrier layer 6, counter electrode 7. A transparent electrode 2 is arranged on the upper surface of...

Embodiment 1

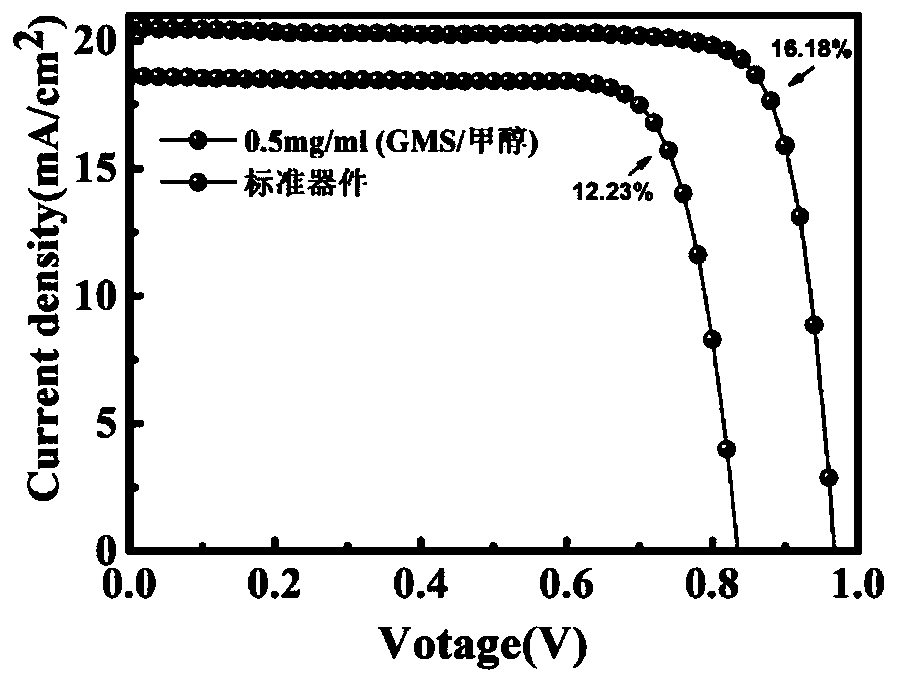

[0049] In order to further illustrate the role of the amphiphilic molecule as the hole modifying layer 32 to prepare the composite hole transport layer, the amphiphilic molecule in this embodiment selects glycerol monostearate (C21H42O4), and its molecular schematic diagram is as follows figure 2 As shown, one end contains a polar group (hydrophilic end) and one end contains a non-polar group (hydrophobic end), and the amphiphilic molecule also includes an ester group.

[0050] This embodiment provides a specific composite hole transport layer and its preparation method.

[0051] The composite hole transport layer includes a PEDOT:PSS layer 31 and glyceryl monostearate (abbreviated as: GMS), the thickness of the PEDOT:PSS layer 31 is 40nm; the thickness of the GMS layer is 8nm.

[0052] The preparation method is as follows: prepare the transparent electrode 2 (here ITO) deposited on the upper surface of the transparent substrate 1 (here is transparent glass) as the base of th...

Embodiment 2

[0055] Based on Example 1, this embodiment provides a method for preparing a perovskite solar cell based on a composite hole transport layer, comprising the following steps:

[0056] The preparation method is as follows:

[0057] (1) Preparatory work: prepare the transparent electrode 2 (here ITO) deposited on the upper surface of the transparent substrate 1 (here is transparent glass) as the base of the hole transport layer, respectively use deionized water, ethanol, acetone, isopropyl Wash the substrate with alcohol or ethanol, dry the substrate with nitrogen after cleaning, and then treat the substrate with ultraviolet and ozone for 15 minutes.

[0058] (2) Preparation of PEDOT:PSS / GMS composite hole transport layer: place the substrate on a spin coater, filter the PEDOT:PSS aqueous solution of CLEVIOS_P_VP_AI_4083 from Heraeus Company with a 0.45 μm filter membrane, and in the aqueous solution of PEDOT:PSS The weight ratio of PEDOT and PSS is 1:6, and then evenly coat the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com