Lithium secondary battery

A lithium secondary battery, lithium salt technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of low initial capacity, reduced battery life, high irreversible capacity, and achieve excellent life characteristics and thermal stability, negative electrode The effect of minimizing the occurrence of deterioration and the decrease in initial capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] (Preparation of non-aqueous electrolyte solution)

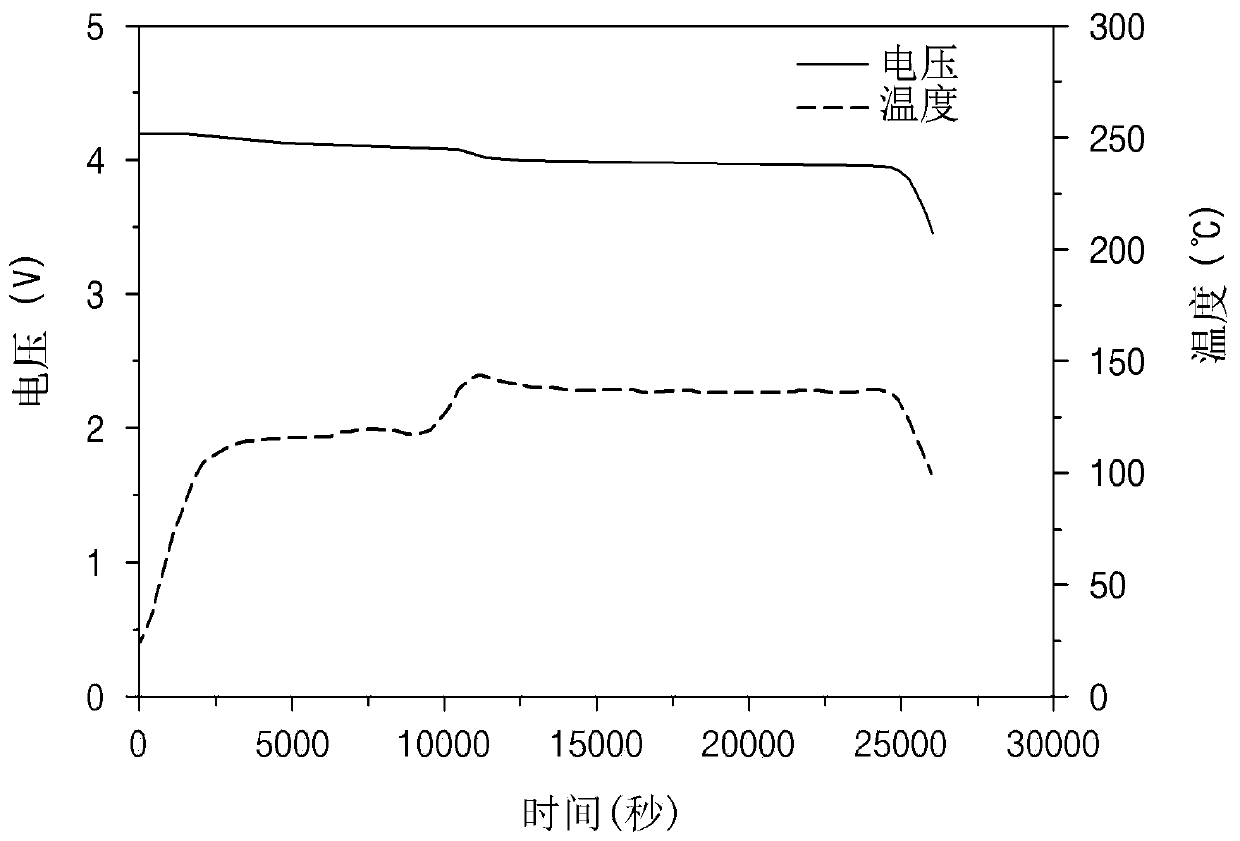

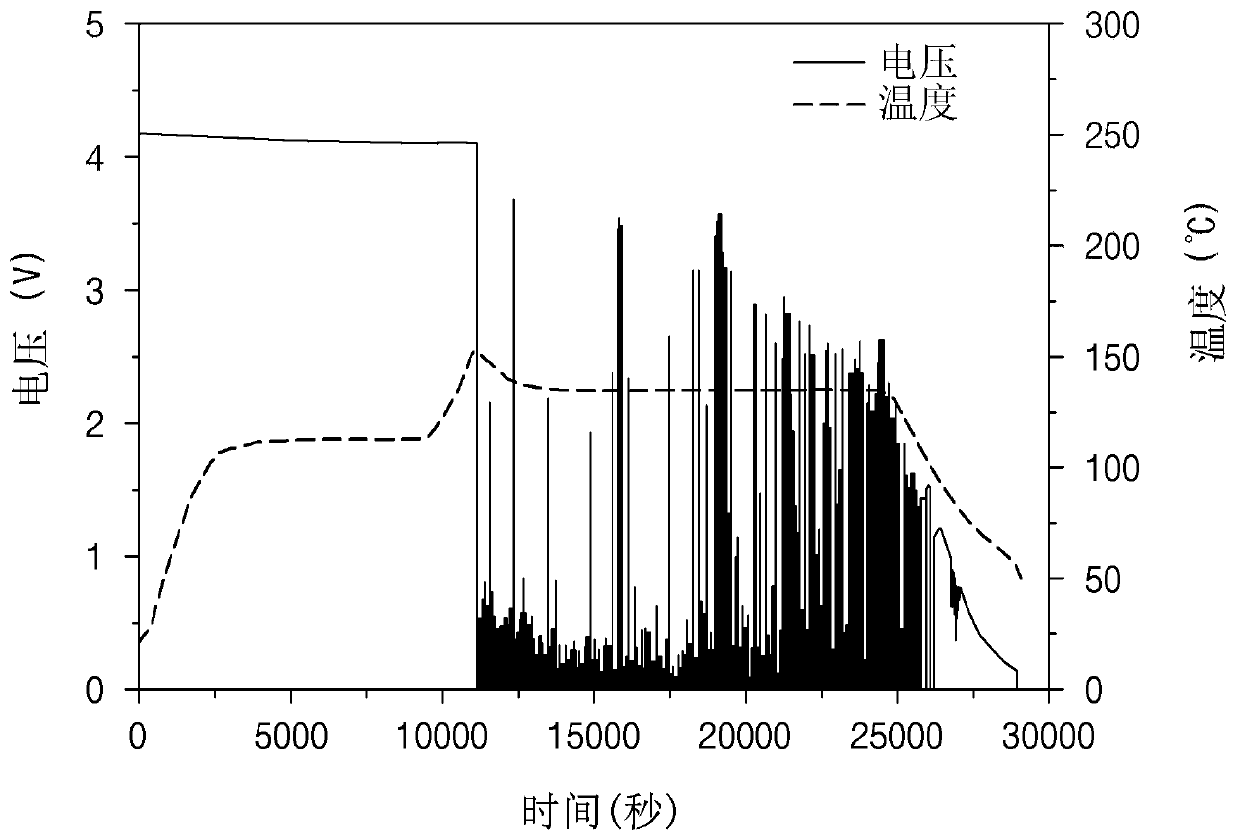

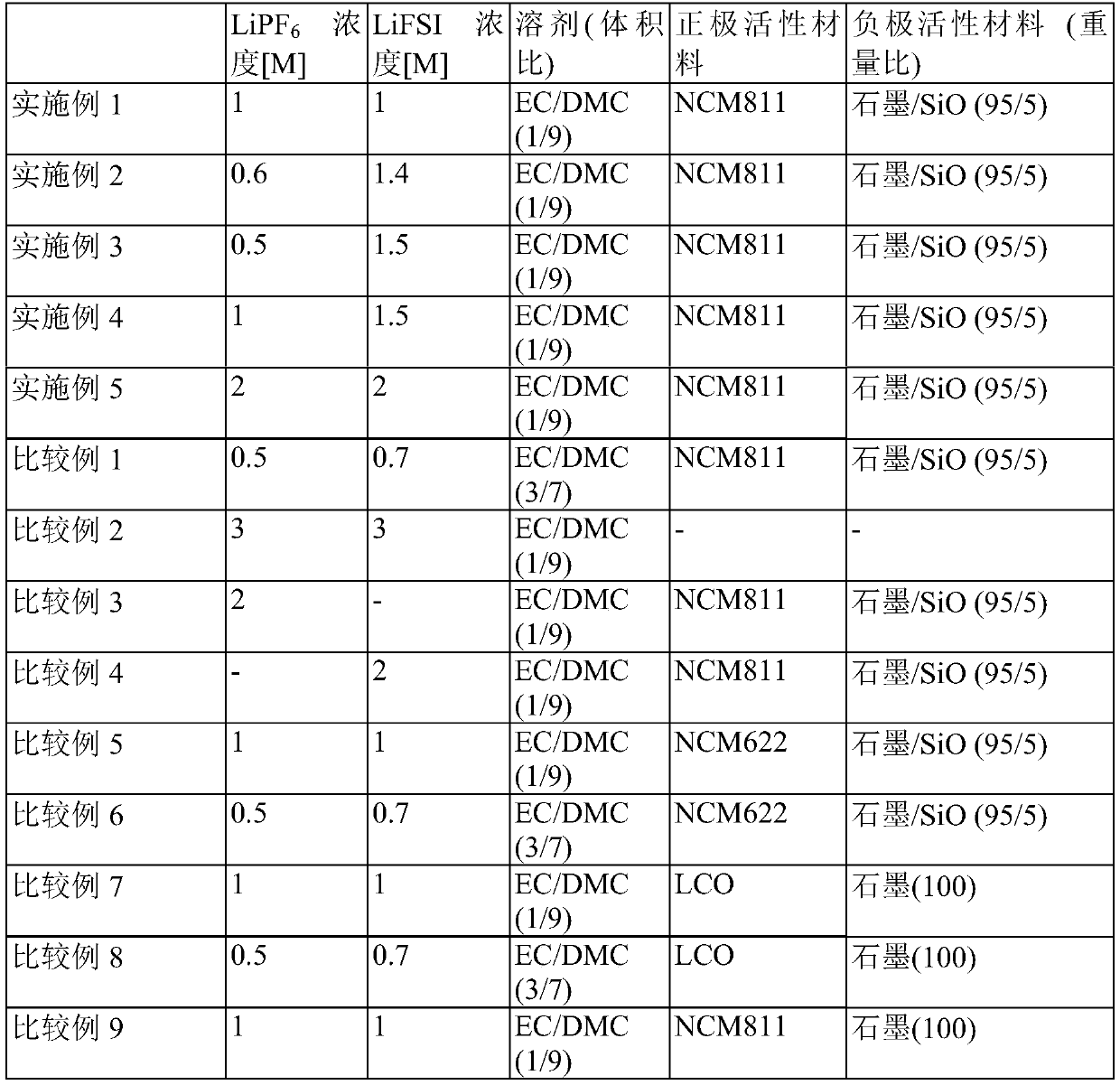

[0085] By adding 2g of vinylene carbonate (VC) and 1g of propane sultone (PS) to 97g of which was dissolved 1.0MLiPF 6 and 1.0M lithium bis(fluorosulfonyl)imide in a non-aqueous organic solvent (a solvent mixture of ethylene carbonate and dimethyl carbonate mixed at a volume ratio of 1:9), to prepare a non-aqueous electrolyte solution.

[0086] (manufacturing of secondary batteries)

[0087] LiNi as the positive electrode active material 0.8 co 0.1 mn 0.1 o 2 (NCM811), Super-P as a conductive material, and polyvinylidene fluoride (PVdF) as a binder were added to N-methyl-2-pyrrolidone (NMP) at a weight ratio of 95:2:3 to A positive electrode slurry (solid content: 17% by weight) was prepared. A 20 μm thick positive electrode current collector (Al thin film) was coated with the positive electrode slurry, dried and rolled to produce a positive electrode.

[0088] Next, a mixture in which graphite and SiO were mixe...

Embodiment 2

[0091] A lithium secondary battery was manufactured in the same manner as in Example 1, except that 0.6M LiPF was dissolved by adding 2 g of vinylene carbonate (VC) and 1 g of propane sultone (PS) to 97 g 6 and 1.4M lithium bis(fluorosulfonyl)imide in a non-aqueous organic solvent (a solvent mixture of ethylene carbonate and dimethyl carbonate mixed at a volume ratio of 1:9), to prepare a non-aqueous electrolyte solution.

Embodiment 3

[0093] A lithium secondary battery was fabricated in the same manner as in Example 1, except that 0.5M LiPF was dissolved by adding 2 g of vinylene carbonate (VC) and 1 g of propane sultone (PS) to 97 g 6 and 1.5 M lithium bis(fluorosulfonyl)imide in a non-aqueous organic solvent (a solvent mixture of ethylene carbonate and dimethyl carbonate mixed at a volume ratio of 1:9), to prepare a non-aqueous electrolyte solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com