Gypsum coated slow-release fertilizer and preparation method and application thereof

A coated slow-release and gypsum technology, applied in application, layered/coated fertilizers, nitrogen fertilizers, etc., can solve the problems of volatilization, nitrogen leaching loss and denitrification loss, single function and effect, and large application amount, etc., to achieve Strong activity, improved stress resistance, and synchronous absorption of crops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

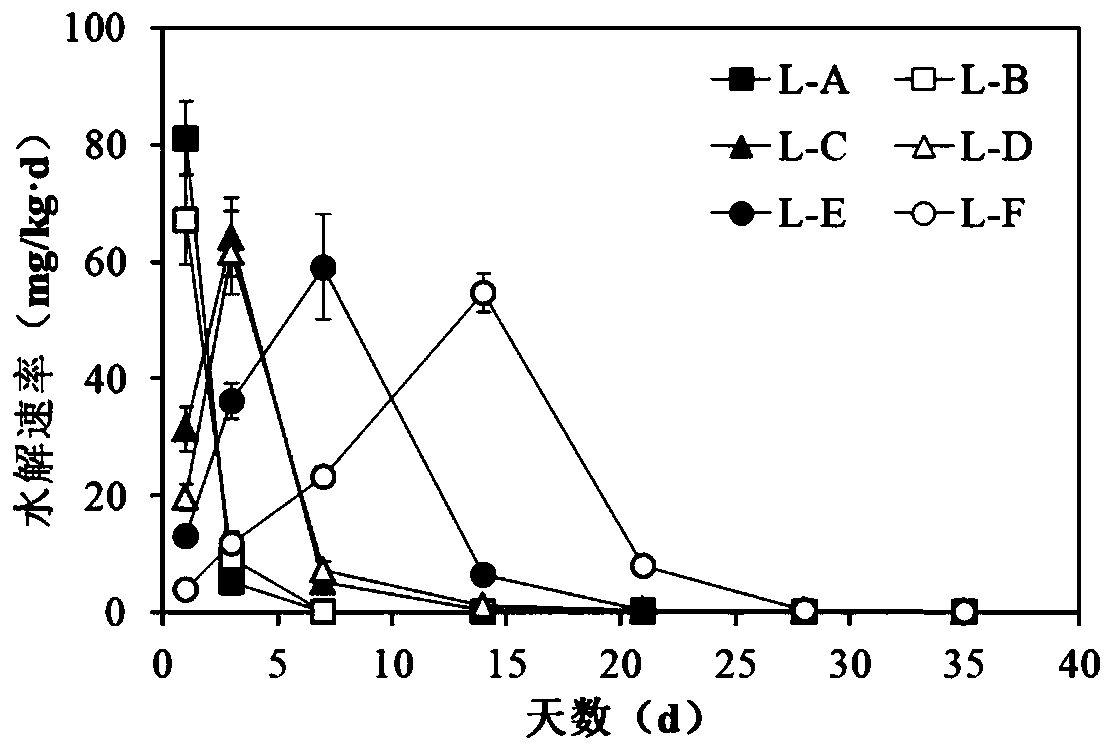

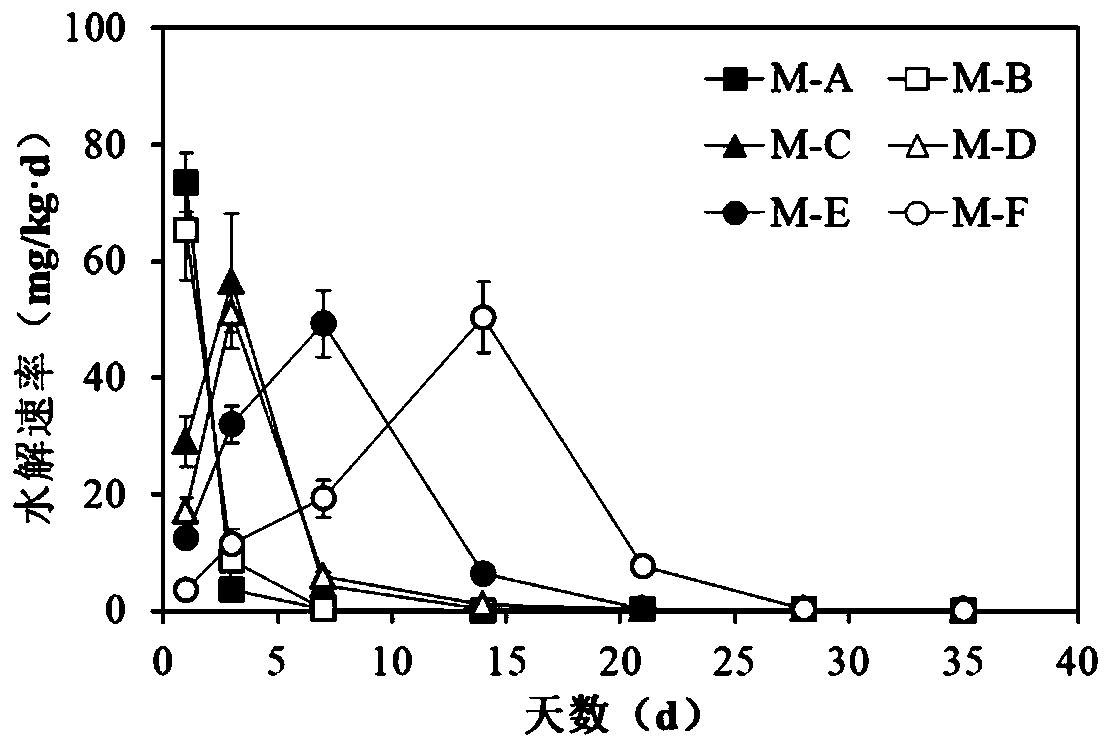

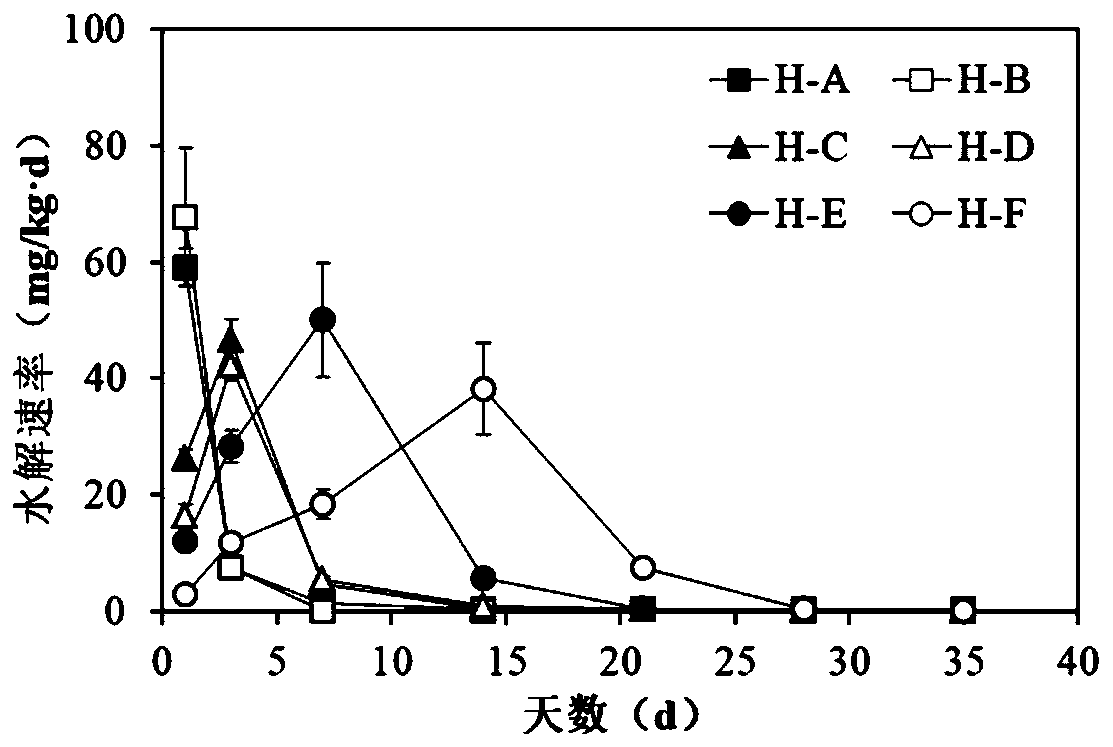

[0047] Severe saline-alkali obstacle cultivated land in Hetao Plain, Inner Mongolia. The soil salinity in the 0-20cm plow layer of the test plot is 3.3-9.1g / kg, the pH is 8.37-8.53, the average organic matter content is 8.45-10.96g / kg, the total nitrogen is 0.39-0.64g / kg, and the alkaline nitrogen is 29.2-41.8mg / kg, available phosphorus is 9.26-12.45mg / kg, and available potassium is 164.9-188.1mg / kg. Location: Chengni Village, Sandaoqiao Town, Hangjinhou Banner, Bayannur City, Inner Mongolia. In May 2017, soil samples of 0-20 cm from the surface layer of saline-alkali cultivated land were collected as soil for indoor constant temperature cultivation experiments. The test time was from June 2017 to September 2017 moon. Three kinds of salt gradients were selected for the test soil, the average salt content was 3.76g / kg (low), 5.49g / kg (medium) and 7.83g / kg (high), the soil was chloride ion-sulfate type saline soil, and the texture was clay loam.

[0048] The main implementat...

Embodiment 2

[0061] Jiangsu coastal mild, moderate and severe saline-alkali land. Select typical test points in three saline-alkali farmlands with different salt gradients, among which the soil salinity of mild saline-alkali test points is 1.73g / kg, the pH is 9.04, and the organic matter is 7.26g / kg; the soil salinity of moderate saline-alkali test points is 3.47g / kg , pH is 8.77, organic matter is 5.75g / kg; soil salinity in severe saline-alkali land is 5.14g / kg, pH is 8.42, organic matter is 3.98g / kg; the whole section of the soil in the test points of the three salt gradients is silt loam, and the soil bulk density of the plow layer is average 1.42 g / cm 3 . Location: Plot No. 4, Tiaobei 11 District, Tiaozini Reclamation District, Dongtai City, Jiangsu Province. The test period was from June 2018 to October 2018. Barley was planted on mild and moderate saline-alkali land, and the straw was crushed and returned to the field after harvest. The ryegrass is planted on the severe saline-alka...

Embodiment 3

[0075] Jiangsu Binhai moderate saline-alkali land, the average soil salinity of 0-20cm plow layer is 2.98g / kg, pH is 8.84, organic matter is 4.67g / kg, total nitrogen is 0.56g / kg, total phosphorus is 0.92g / kg, soil NH 4 + -N content 3.27mg / kg, NO 3 - -N content is 11.44mg / kg, the soil texture is silt loam, and the average soil bulk density of the plow layer is 1.40g / cm 3 . Location: Plot No. 2, Tiaobei 11 District, Tiaozini Reclamation District, Dongtai City, Jiangsu Province, the test period is from November 2018 to May 2019, using a plot test with an area of 24m 2 (4m×6m), the test crop is barley, variety Haihua No.1. The main implementation links are as follows:

[0076] (1) CK: without any nitrogen fertilizer;

[0077] (2) F: Both base fertilizer and top dressing are conventional urea;

[0078] (3) FD: Apply slow-release fertilizer as base fertilizer, the components are 45 parts of urea, 2 parts of nitrification inhibitor DMPP, 0.4 part of nitrification inhibitor C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com