A kind of method for producing 1,1,2-trichloroethane by photochlorination of vinyl chloride

A technology of trichloroethane and vinyl chloride, which is applied in the field of preparation of organic intermediates, can solve the problems of excessive three wastes and easy coking, and achieve the effects of improving production capacity, environmental protection, and reducing the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

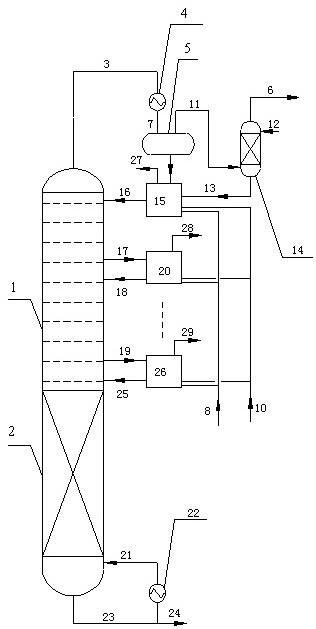

Image

Examples

Embodiment 1

[0025] In a rectification tower with a diameter of 0.8m and 15 trays, the number of trays in the reactive distillation area is 1, and the number of trays in the stripping area is 14. 3 The tank-type side reactors are connected, in which the condensate of the vapor phase material at the top of the tower and the 1,2-dichloroethane absorption liquid of the tail gas all enter the first side reactor, and the outlet materials of the side reactor are returned to the first column of the rectification tower Plates (the number of plates is counted from top to bottom), and the material between the rectification column and the side reactor is transported by a pump.

[0026] The side reactor is equipped with a light source of partial ultraviolet wavelength and 1,2-dichloroethane. The feed flow rate of tail gas 1,2-dichloroethane absorption liquid to the side reactor is 0.2kmol / h, the feed flow rate of vinyl chloride to the side reactor is 4kmol / h, and the feed rate of chlorine gas to the s...

Embodiment 2

[0028] In a rectification tower with a diameter of 0.8m and 15 trays, there are 7 trays in the reactive distillation area and 8 trays in the stripping area, and 2 units with a volume of 3m 3 The tank-type reactors are connected, and the number of plates between the reactors is 5. Among them, the condensate of the vapor phase material at the top of the tower and the 1,2-dichloroethane absorption liquid of the tail gas all enter the first side reactor. The material from the outlet of the reactor returns to the first tray of the rectification tower (the number of trays is counted from top to bottom); the material from the sixth rectification tray enters the second reactor, and the outlet material of the side reactor returns to the rectification On the 7th tray of the tower, the material between the rectification tower and the side reactor is transported by a pump.

[0029] Each side reactor is equipped with a light source of partial ultraviolet wavelength and 1,2-dichloroethane. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com