High-dispersity BOPET opening smooth master batch and preparation method thereof

A highly dispersive and smooth technology, applied in the field of plastics, can solve the problems of uneven distribution of film surface, poor film haze uniformity, affecting production continuity, etc., to reduce poor appearance, good opening effect, and improve sustainability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

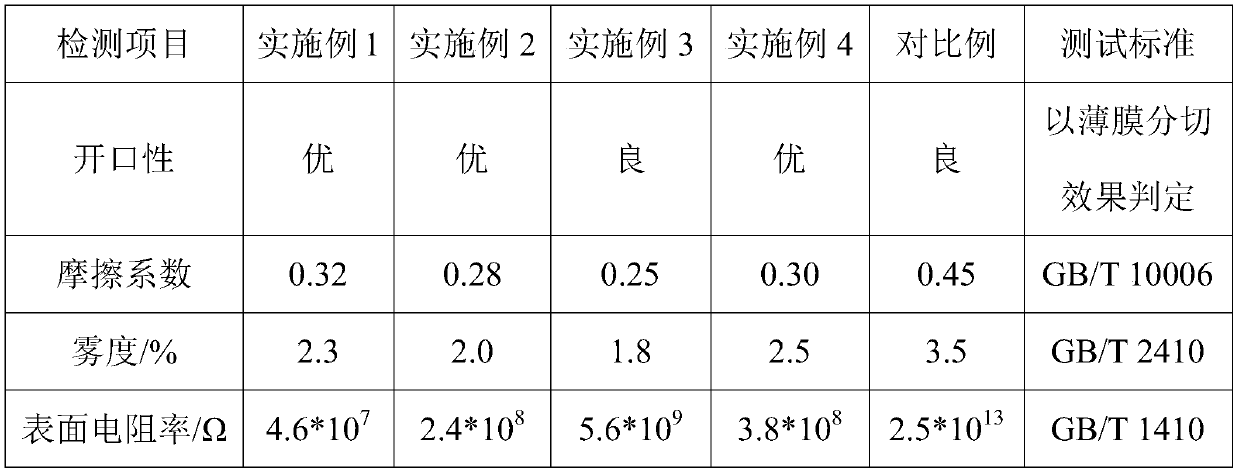

Examples

Embodiment 1

[0019] A high-dispersibility BOPET opening smooth masterbatch proposed by the present invention is prepared by blending and extruding the following components by weight percentage: 90% of component A, 5% of component B, and 5% of component C;

[0020] Component A is prepared by polymerization of raw materials in the following percentages by weight: nanoporous silica 3.92%, purified terephthalic acid 42%, ethylene glycol 54%, additives 0.08%; wherein, nanoporous silica consists of spherical It is composed of amorphous nanoporous silicon dioxide in a weight ratio of 1:1; the additive is composed of antimony trioxide and trimethyl phosphate in a weight ratio of 1:1. The preparation of component A is as follows: add all the raw materials into the beating tank, stir for 1.5 hours, then pass through nitrogen protection, raise the temperature of the beating tank to 180°C, the heating rate is 10°C / min, and continue heating and stirring for 30 minutes to obtain the product;

[0021] Co...

Embodiment 2

[0025] A high-dispersion BOPET opening smooth masterbatch proposed by the present invention is obtained by blending and extruding the following components by weight percentage: 92% of component A, 4% of component B, and 4% of component C;

[0026] Component A is prepared by polymerization of the following raw materials in weight percentage: 3.90% of nanoporous silica, 43% of purified terephthalic acid, 53% of ethylene glycol, and 0.10% of additives; wherein, nanoporous silica is made of spherical It is composed of amorphous nanoporous silicon dioxide in a weight ratio of 2:3; the additive is composed of antimony trioxide and trimethyl phosphate in a weight ratio of 2:3. The preparation of component A is as follows: add all the raw materials into the beating tank, stir for 1 hour, then pass through nitrogen protection, raise the temperature of the beating tank to 175°C, the heating rate is 9.5°C / min, and continue heating and stirring for 20 minutes to obtain the product;

[002...

Embodiment 3

[0031] A high-dispersion BOPET open smooth masterbatch proposed by the present invention is prepared by blending and extruding the following components by weight percentage: 94% of component A, 3% of component B, and 3% of component C;

[0032] Component A is prepared by polymerization of the following raw materials in weight percentage: 3.88% of nanoporous silica, 44% of purified terephthalic acid, 52% of ethylene glycol, and 0.12% of additives; wherein, nanoporous silica is made of spherical It is composed of amorphous nanoporous silicon dioxide in a weight ratio of 3:2; the additive is composed of antimony trioxide and trimethyl phosphate in a weight ratio of 3:2. The preparation of component A is as follows: add all the raw materials into the beating tank, stir for 2 hours, then pass through nitrogen protection, raise the temperature of the beating tank to 185°C, the heating rate is 10.5°C / min, and continue heating and stirring for 40min to obtain the product;

[0033] Com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com