A kind of processing method of golden yellow oxide film on the surface of brass products

A technology of brass products and processing methods, applied in the direction of metal material coating technology, etc., can solve the problems of complex process flow, high cost, and large pollution, and achieve the effect of firm color film, low cost, and small pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

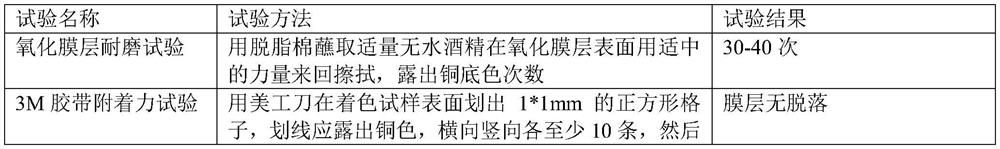

Examples

Embodiment 1

[0029] A method of processing a golden oxide film for a brass article, including the following steps:

[0030] (1) Preprocessing: sand blasting surface on the surface of the brass article, removes the surface oxide layer and oil, and then purge cleaning in the water, then rinse and blow it with water.

[0031] (2) Formulated golden chemical colored liquid, the formulation of golden chemical colorants is: 5 g of aqueous yellow metal complex dye / liter, 1 g / liter, 1 g of citric acid, 1 g / liter, penetrant JFC 0.1 g / liter, ethanol 10 (95%) ml / L, water rate.

[0032] (3) Surface Coloration: Evenly heated by the brass article after the step (1), the flame gun is uniformly heated and maintaining its surface temperature at 120-150 ° C, and the golden chemical colorant in the brass product is evenly sprayed with the surface of the brass article with a watering can. -100, until the uniform golden colored layer of the brass article has a uniform golden colored layer, and finally rin...

Embodiment 2

[0034] A method of processing a golden oxide film for a brass article, including the following steps:

[0035] (1) Preprocessing: sand blasting surface on the surface of the brass article, removes the surface oxide layer and oil, and then purge cleaning in the water, then rinse and blow it with water.

[0036] (2) Formulate golden chemical coloring liquid, the formulation of golden chemical colorants is 20 g / liter, 6 g / liter of sodium dichromate, 3 grams / liter, penetrant JFC 0.3 g / liter, ethanol (95%) 20 ml / L, water rate.

[0037] (3) Surface Coloration: Evenly heated by the brass product after the step (1), the flame gun is uniformly heated and maintaining its surface temperature at 120-150 ° C, and the golden-yellow chemical colorant is uniformly brush with a brush. Coated 40-50 times until a uniform golden colored layer appeared on the surface of the brass article, and finally rinsed the surface of the brass product with water to remove the surface.

[0038] (4) Post-...

Embodiment 3

[0040] A method of processing a golden oxide film for a brass article, including the following steps:

[0041] (1) Preprocessing: Chemically laminating the surface of the brass article, remove the surface oxide layer and oil, and then further polish it in the water, then rinse and blow it with water. The chemical acid washing is soaked in normal temperature, and time is about 5 minutes. The formulation of the chemical acid washing liquid washing liquid was: concentrated sulfuric acid (98%) of 100 mL / L, concentrated hydrochloric acid (36%) 30 mL / L, urea 6 g / L, OP-10 emulsifier 0.8 ml / L, Water rate.

[0042] (2) Formulate golden chemical coloring liquid, the formulation of the golden chemical coloring liquid is: 8 g / liter of aqueous yellow metal complex dye, 2 g / liter, 1 gram of tartaric acid, 1 g of tartaric acid, 1 gram of tartaric acid 1 Gram / liter, penetrant JFC 0.1 g / liter, ethanol (95%) 10 mL / L, water rate.

[0043] (3) Surface Coloration: Evenly heated by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com