A preparation method of cerium oxide nanorod array/graphene composite material and its application in photocathode protection

A technology of nanorod arrays and composite materials, applied in the field of preparation of cerium oxide nanorod arrays/graphene composite materials, can solve the problem that cerium oxide nanoparticles cannot conduct electrons quickly and effectively, so as to promote directional transmission and improve anti-corrosion performance , The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

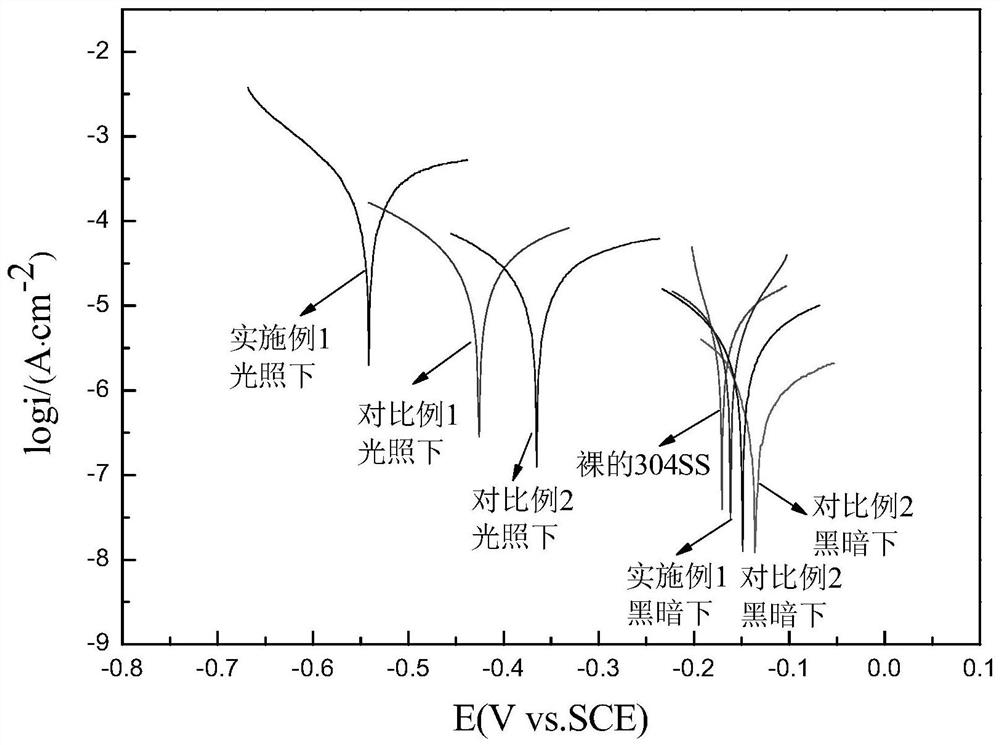

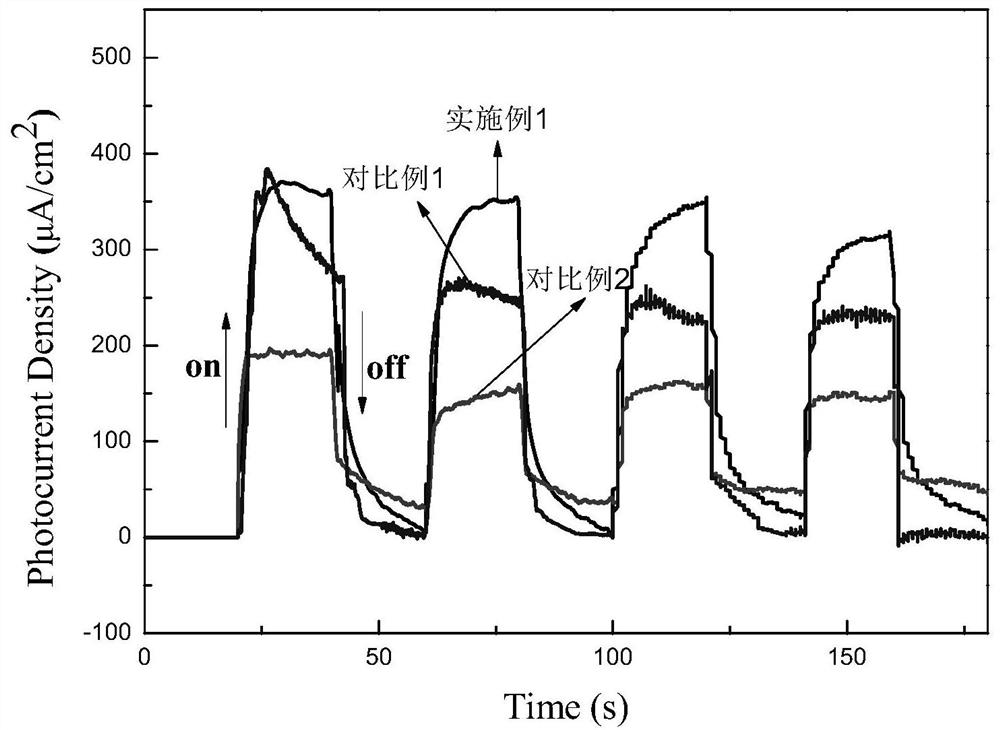

Embodiment 1

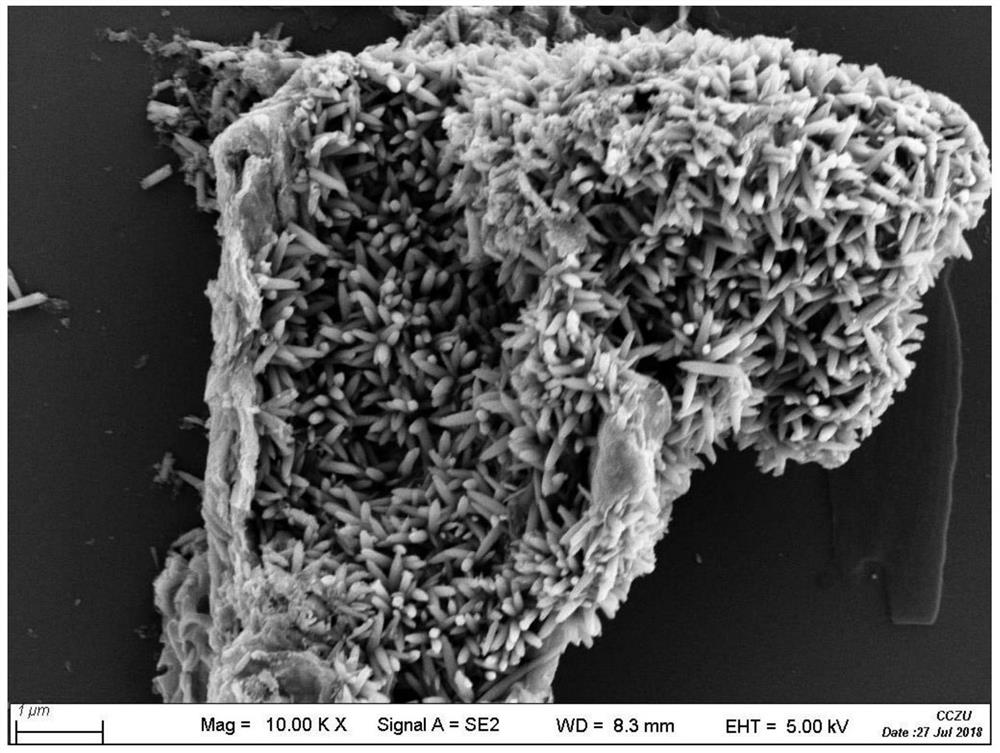

[0021] 1. Take 0.01 mol / L of nitrate as an electrolyte, 0.05 mol / L of potassium chloride is auxiliary electrolyte, 0.1 mol / L of ammonium chloride is a stabilizer, and the amount of nitrate and ammonium chloride material It is 1: 2, and the amount of material of cerium nitrate and potassium chloride is 1: 0.1, Ti is the substrate, and Pt is the counter electrode, saturated Ag / Ag electrodes as a reference electrode, at 50 ° C, 0.5 mA / cm. 2 Current density at the potential for 80 min, in CEO 2 Nuclear growth CEO on seed layer 2 Nano stick array.

[0022] 2. Formulated 50ml 0.025mol / L SNCL 2 Ethanol solution to activate CEO 2 Nano stick array, weigh a quantitative oxide ink in 100 ml of deionized water, will activate CEO 2 The nano-bar array is immersed in an oxide ink solution at 50 ° C for 0.5 h, followed by NA 2 SO 4 Rinse with deionized water, dried in vacuo 50 ° C to obtain a cerium oxide nano-array / graphene composite.

Embodiment 2

[0024] 1. A ratio of the amount of 0.20 mol / L of potassium chloride is an auxiliary electrolyte, 0.3 mol / L of ammonium acetate is a stabilizer, and the amount of ammonium nitrate and ammonium acetate. It is 1: 1, the ratio of the substance of ammonium nitrate and potassium chloride is 1: 5, ITO conductive glass is a substrate, Pt is the counter electrode, saturated Ag / Ag electrodes as a reference electrode, at 70 ° C, 3 mA / cm 2 Current density under low potential deposition 120min seed layer growth CEO 2 Nano stick array.

[0025] 2. Sncl formulated 100ml 0.05mol / L 2 Ethanol solution to activate CEO 2 Nano stick array, weigh a quantitative oxide ink dissolve in 200 ml of deionized water, will activate CEO 2 The nano-bar array is immersed in an oxide ink solution for 2 h at 70 ° C, followed by Na. 2 SO 4 Flush with deionized water, dried in vacuo 70 ° C to obtain a cerium oxide nano-array / graphene composite.

Embodiment 3

[0027] 1. Ammonium chloride in 0.05 mol / L is an electrolyte, 0.35 mol / L of potassium chloride is an auxiliary electrolyte, 0.5 mol / L of six methyl tetramine is a stabilizer, ammonium chloride and six times a methyl group The ratio of the substance of the tetraamine is 1: 0.5, the ratio of the substance of ammonium chloride and potassium chloride is 1: 10, the FTO conductive glass is the substrate, the Pt is the electrode, saturated Ag / AgCl electrode Compared with electrode, at 90 ° C, 5.5mA / cm 2 Current density at a potential deposited 160 min seed layer growth CEO 2 Nano stick array.

[0028] 2. Formulate SNCL of 150ml 0.075mol / L 2 Ethanol solution to activate CEO 2 Nano stick array, weigh a quantitative oxide ink dissolve in 300 ml of deionized water, will activate CEO 2 The nano-bar array is immersed in an oxide ink solution at 90 ° C for stirring at 90 ° C for 3.5 h, followed by NA 2 SO 4Rinse with deionized water, dried in vacuo 90 ° C to obtain a cerium oxide nan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com