Colored dry-mixed mortar and preparation method thereof

A dry-mixed mortar and color technology, applied in the field of titanium dioxide, can solve the problems of poor weather resistance, pan-alkali, etc., and achieve the effect of enhancing vividness and strong heating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

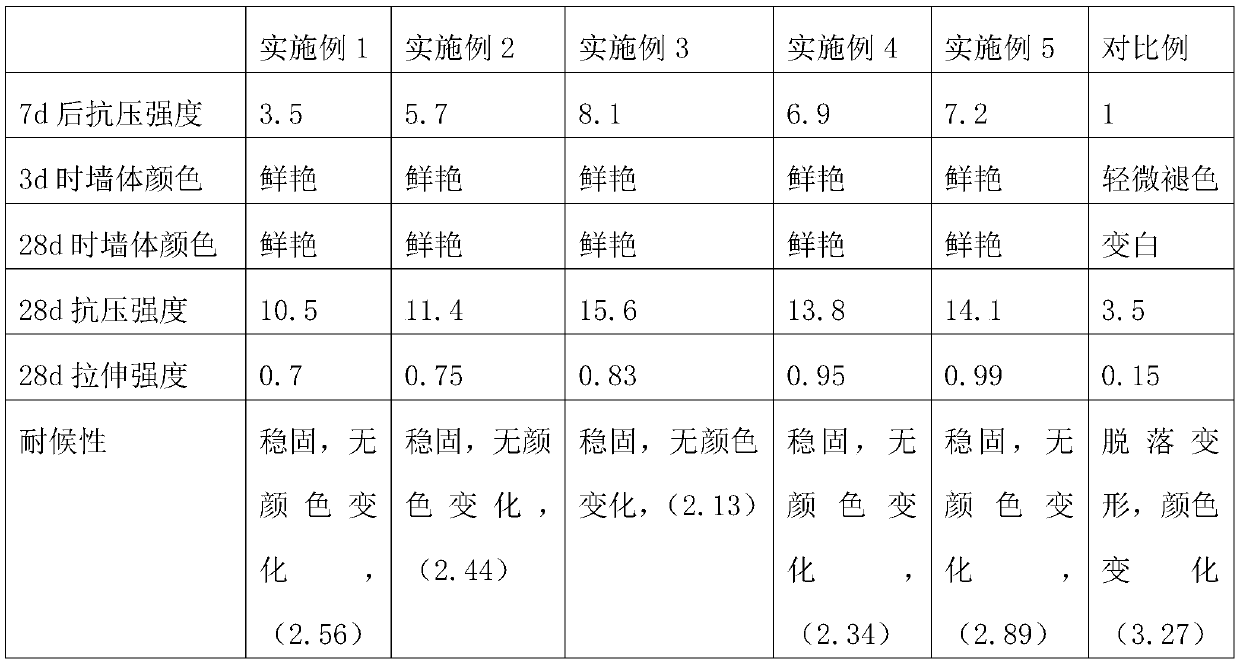

Examples

Embodiment 1

[0095] To prepare colored dry mix mortar:

[0096] (1) Preparation of modified titanium dioxide:

[0097] Raw materials (by weight): 1 part of butyl titanate, 10 parts of water;

[0098] A1. Add butyl titanate into the reactor, at a temperature of 85°C, N 2 Gasification of butyl titanate under protection;

[0099] A2. Add water into the reactor; the reaction temperature is 525°C and the pressure is 1.01×10 5 Pa, N 2 Reaction under the protection of (nitrogen flow rate 1L / min, water vapor flow rate 1L / min, reaction time 30min) to obtain R818 type nano-TiO 2 ;

[0100] A3. The nano-TiO obtained in step A2 2 placed under inert gas CO 2 Cool down to 23°C in the atmosphere;

[0101] A4. The TiO obtained by cooling in step A3 2 Placed in a 45μm round-hole sieve to control TiO 2 The content is greater than 98%, the sieve residue is less than 0.01%, the volatile matter at 105°C is less than 0.05%, and the L value ranges from 98.5 to 100 to obtain the finished product of modi...

Embodiment 2

[0121] To prepare colored dry mix mortar:

[0122] (1) Preparation of modified titanium dioxide:

[0123] Raw materials (by weight): 1 part of butyl titanate, 15 parts of water;

[0124] A1. Add butyl titanate into the reactor, at a temperature of 60°C, N 2 Gasification of butyl titanate under protection;

[0125] A2. Add water into the reactor; the reaction temperature is 510°C and the pressure is 1.5×10 5 Pa, N 2 Reaction under the protection of (nitrogen flow rate 1L / min, water vapor flow rate 1L / min, reaction time 30min) to obtain R818 type nano-TiO 2 ;

[0126] A3. The nano-TiO obtained in step A2 2 placed under inert gas CO 2 Cool down to 22°C in the atmosphere;

[0127] A4. The TiO obtained by cooling in step A3 2 Placed in a 45μm round-hole sieve to control TiO 2 The content is greater than 98%, the sieve residue is less than 0.01%, the volatile matter at 105°C is less than 0.05%, and the L value ranges from 98.5 to 100 to obtain the finished product of modif...

Embodiment 3

[0147] To prepare colored dry mix mortar:

[0148] (1) Preparation of modified titanium dioxide:

[0149] Raw materials (by weight): 1 part of butyl titanate, 6 parts of water;

[0150] A1. Add butyl titanate into the reactor, at a temperature of 110°C, N 2 Gasification of butyl titanate under protection;

[0151] A2. Add water into the reactor; the reaction temperature is 530°C and the pressure is 0.5×10 5 Pa, N 2 Reaction under the protection of (nitrogen flow rate 1L / min, water vapor flow rate 1L / min, reaction time 20min) to obtain R818 type nano-TiO 2 ;

[0152] A3. The nano-TiO obtained in step A2 2 placed under inert gas CO 2 Cool down to 24°C in the atmosphere;

[0153] A4. The TiO obtained by cooling in step A3 2 Placed in a 45μm round-hole sieve to control TiO 2 The content is greater than 98%, the sieve residue is less than 0.01%, the volatile matter at 105°C is less than 0.05%, and the L value ranges from 98.5 to 100 to obtain the finished product of modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com