The preparation method of vinyl sulfate

A technology of vinyl sulfate and vinyl sulfite, which is applied in the field of preparation of vinyl sulfate, can solve the problems of low yield and low purity of vinyl sulfate, and achieve the effects of high molar yield, improved purity, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

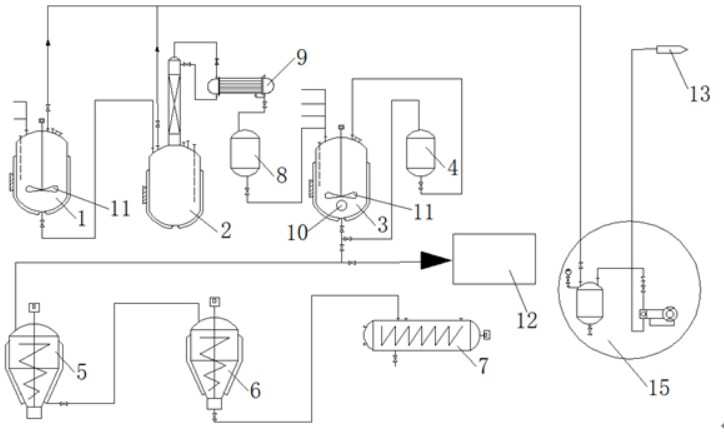

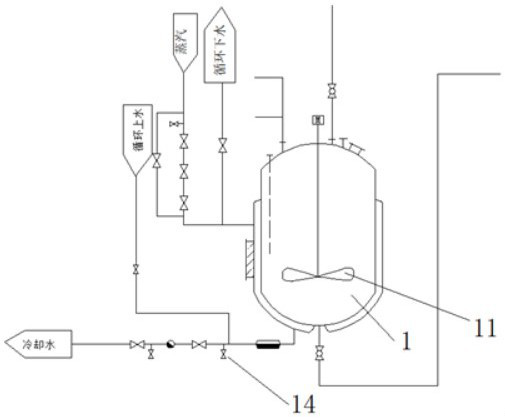

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of vinyl sulfate, comprises the steps:

[0030] 1) Add ethylene glycol dropwise to thionyl chloride at room temperature, raise the temperature to 50~80°C for 2~4 hours after the dropwise addition, and then carry out vacuum treatment to obtain a reaction solution containing vinyl sulfite;

[0031] 2) Purify the vinyl sulfite-containing reaction liquid in step 1) by rectification and purification under vacuum conditions to obtain vinyl sulfite with a purity greater than 99.2%;

[0032] 3) Mix vinyl sulfite with a purity greater than 99.2% in step 2) and ethylene dichloride, add sodium hypochlorite solution dropwise to the obtained mixed solution for premixing, stir and stand after the dropwise addition, and make The aqueous phase and the organic phase are separated, and the aqueous phase is separated to obtain the organic phase;

[0033] The whole process of the premixing is carried out under normal pressure, and the te...

Embodiment 1

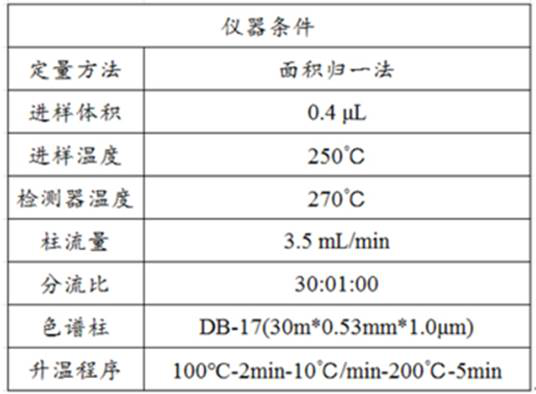

[0059] Before starting work, purge and test the overall system, turn on the acid absorption system, weigh 2950kg of thionyl chloride into the synthesis reaction kettle, add 1300kg of industrial grade ethylene glycol dropwise, and control the temperature of the system not to exceed 30°C, which takes 8 hours After the dropwise addition, continue to stir for 2 hours, then raise the temperature to 50°C and keep it warm for 4 hours. Gas chromatography detects that there is no raw material ethylene glycol remaining. At this time, the system is a light brown clear solution. A reaction liquid containing vinyl sulfite was prepared (the content of vinyl sulfite was 98.2%).

[0060] Transfer the reaction solution containing vinyl sulfite after the reaction to the rectification tank, keep the pressure in the tank at -0.1MPa, control the reflux ratio to 5:1, and continue to extract the former fraction. When the ES content reaches more than 99.2%, Switch to the intermediate product reflux t...

Embodiment 2

[0075] Before starting work, purge and test the overall system, turn on the acid absorption system, weigh 2790kg of thionyl chloride into the synthesis reaction kettle, add 1185kg of industrial grade ethylene glycol dropwise, and control the temperature of the system not to exceed 25°C, which takes 8 hours After the dropwise addition, continue to stir for 3 hours, then raise the temperature to 65°C and keep it warm for 2 hours. Gas chromatography detects that there is no raw material ethylene glycol remaining. At this time, the system is a light brown clear solution. A reaction solution containing vinyl sulfite was prepared (the content of vinyl sulfite was 98.4%).

[0076] After the reaction, the reaction solution containing vinyl sulfite is transferred to the rectification tank, the pressure in the tank is kept at -0.095MPa, the reflux ratio is controlled at 5:1, and the fraction before extraction is continued. When the ES content reaches more than 99.2%, Switch to the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com