Novel gas generating agent for MGG

A gas generating agent, a new type of technology, applied in the generation of compressed gas, offensive equipment, explosives, etc., can solve the problems of chemical residues that cannot be filtered, explosion temperature, and easy deflagration, etc., to achieve improved safety factor, high safety factor, flame good sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

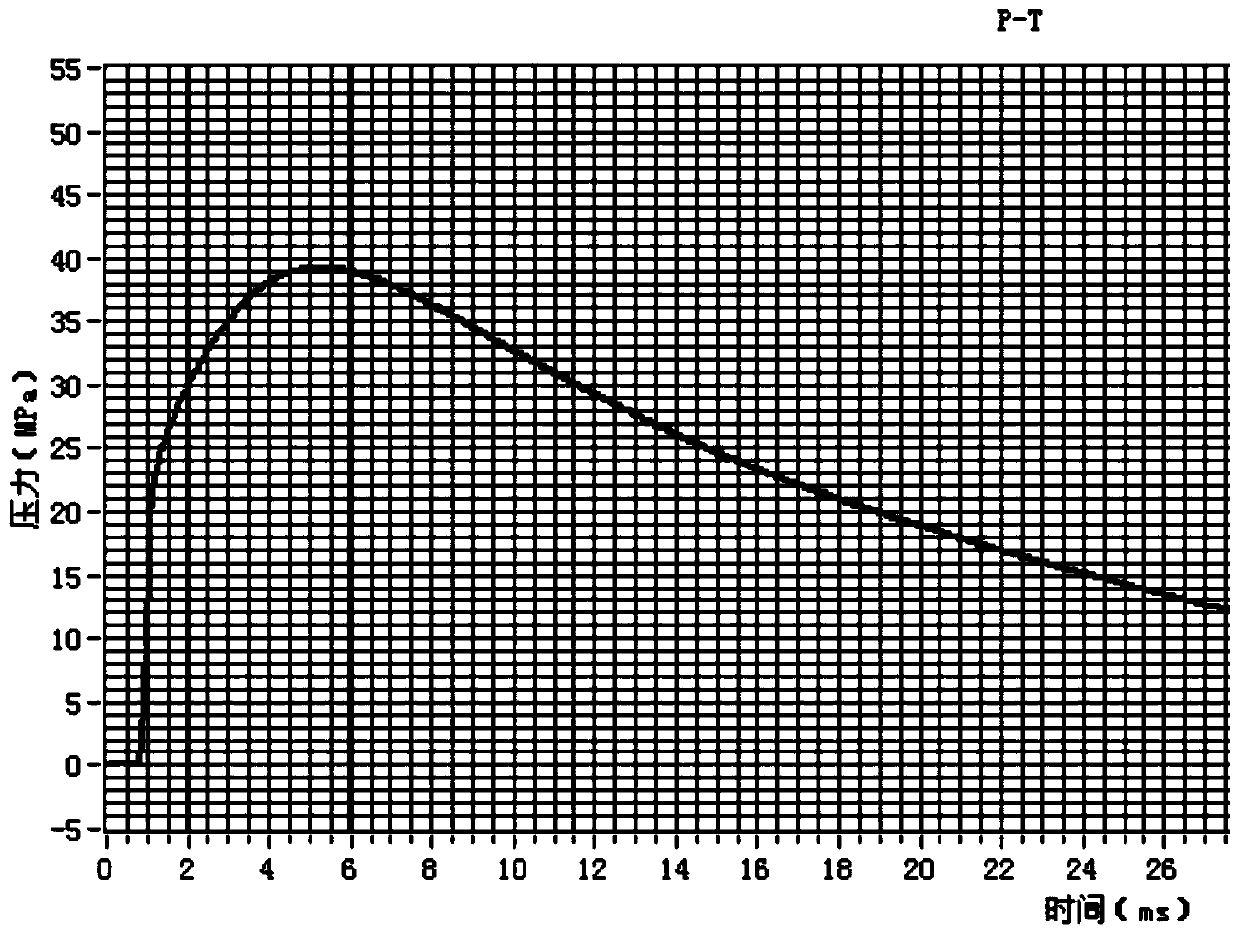

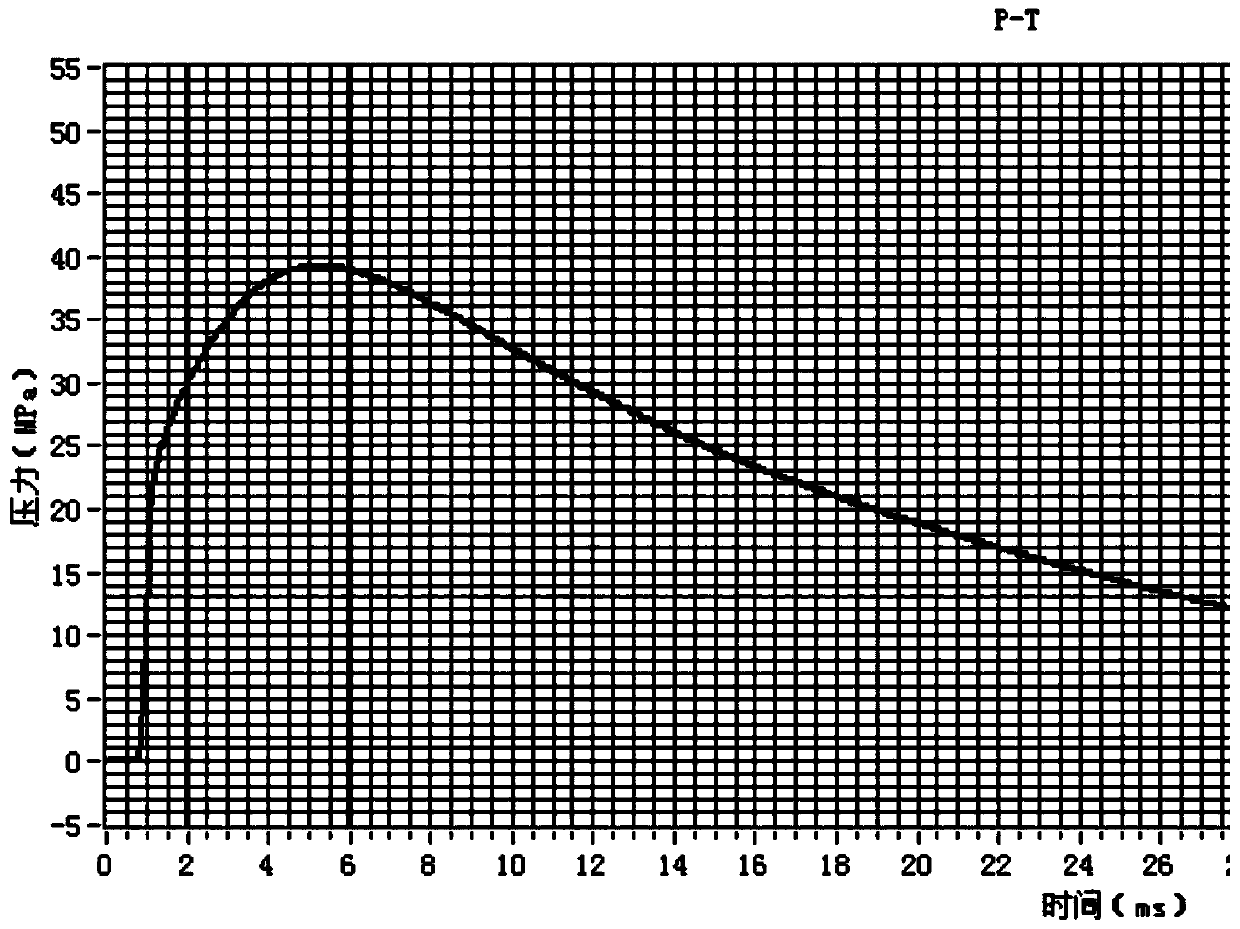

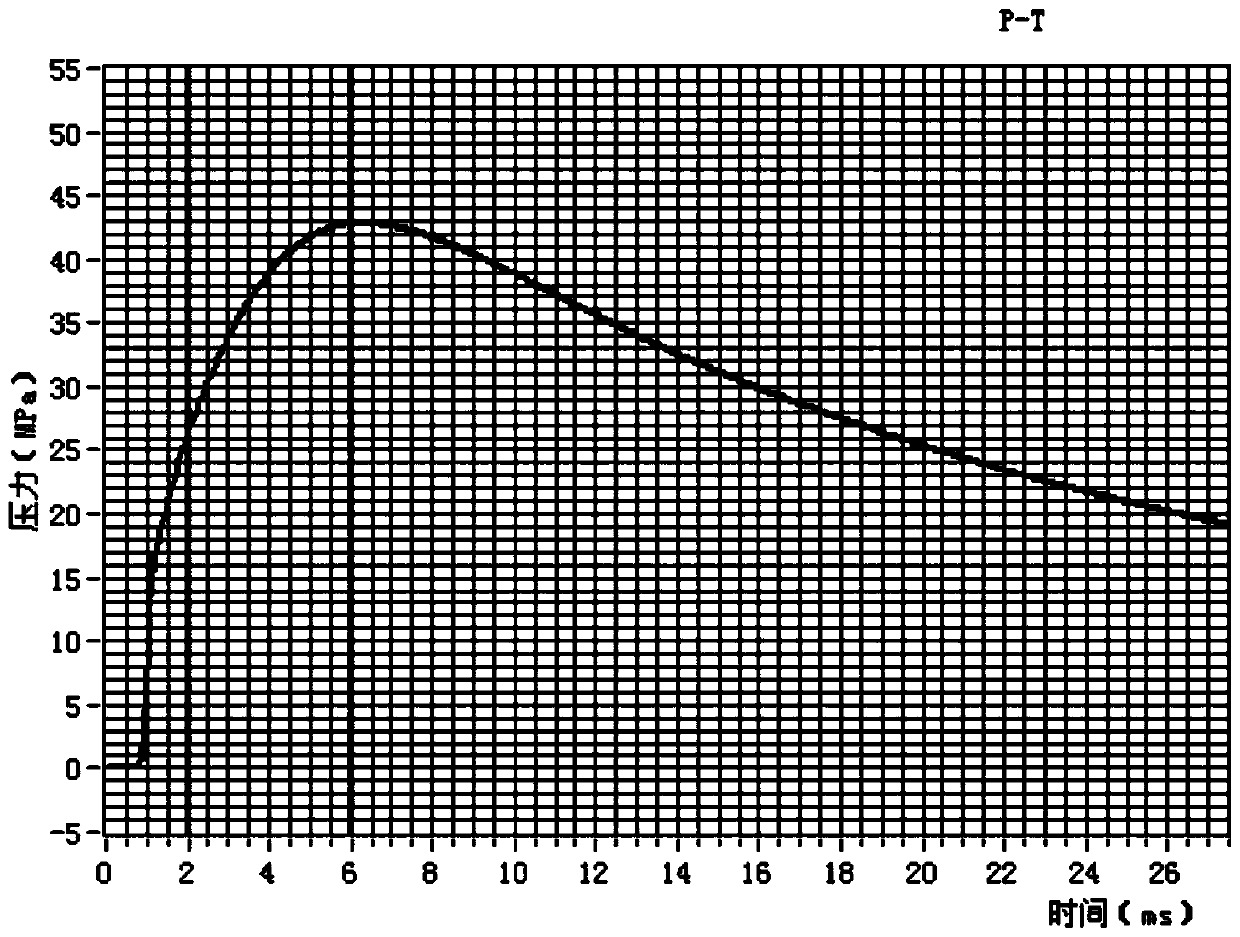

Image

Examples

Embodiment 1

[0019] A novel gas generating agent for MGG of the present invention comprises the following steps: 1) mixing powdered ammonium nitrate and shellac solvent in a ratio of 7:3, then wet mixing for 15 minutes, then drying for 30-40 minutes, and then sieving and granulating After forming 20-40 mesh granules, dry for 40-60 minutes to obtain the first agent; 2) firstly dry and sieve potassium nitrate, and then weigh potassium nitrate, boron powder and Phenolic resin, wet mixing time 15min, dry mixing time 15min and granulation into 20 mesh to 40 mesh, drying for 1 hour to obtain the second agent; 3) Mix the first agent and the second agent at a ratio of 8:2 to obtain a gas generator.

[0020] 1. Concentration test of harmful gas products

[0021] Take 1.2g of the gas generating agent prepared in Example 1, assemble it in the MGG, and test the amount of gas generated after the agent explodes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com