Refining method of doxycycline hydrochloride

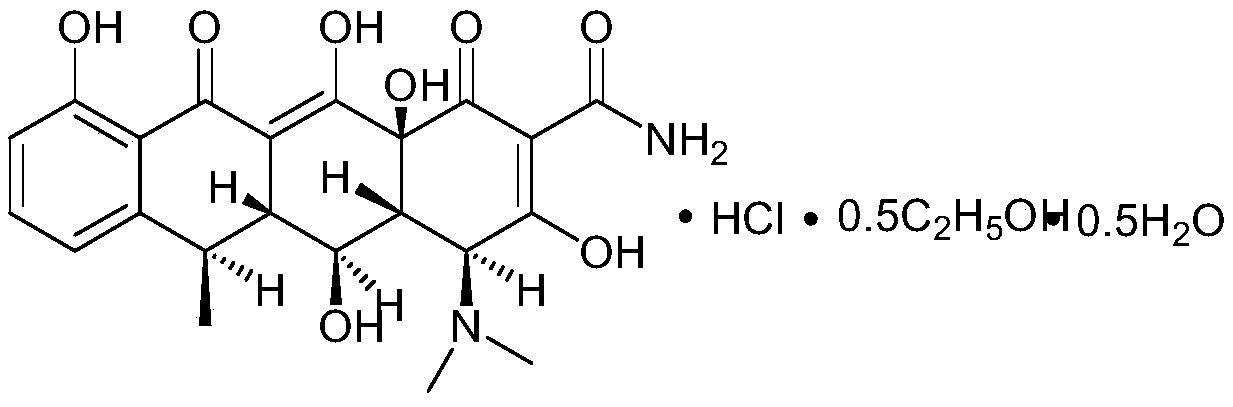

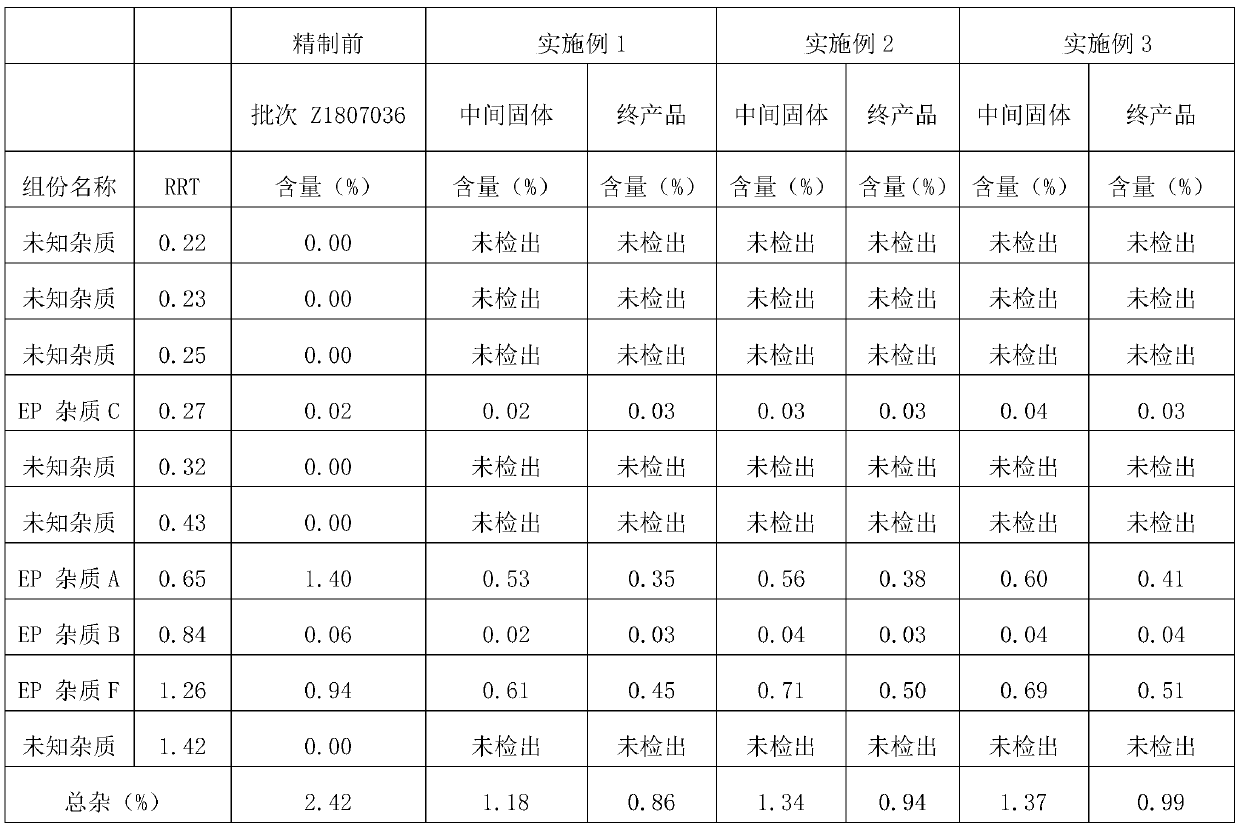

A technology of doxycycline hydrochloride and a refining method, which is applied in the field of chemical substance purification, can solve the problems of increased side effects, low content, and high total impurity content of preparations, and achieve the effects of reducing toxic and side effects, simple refining steps, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

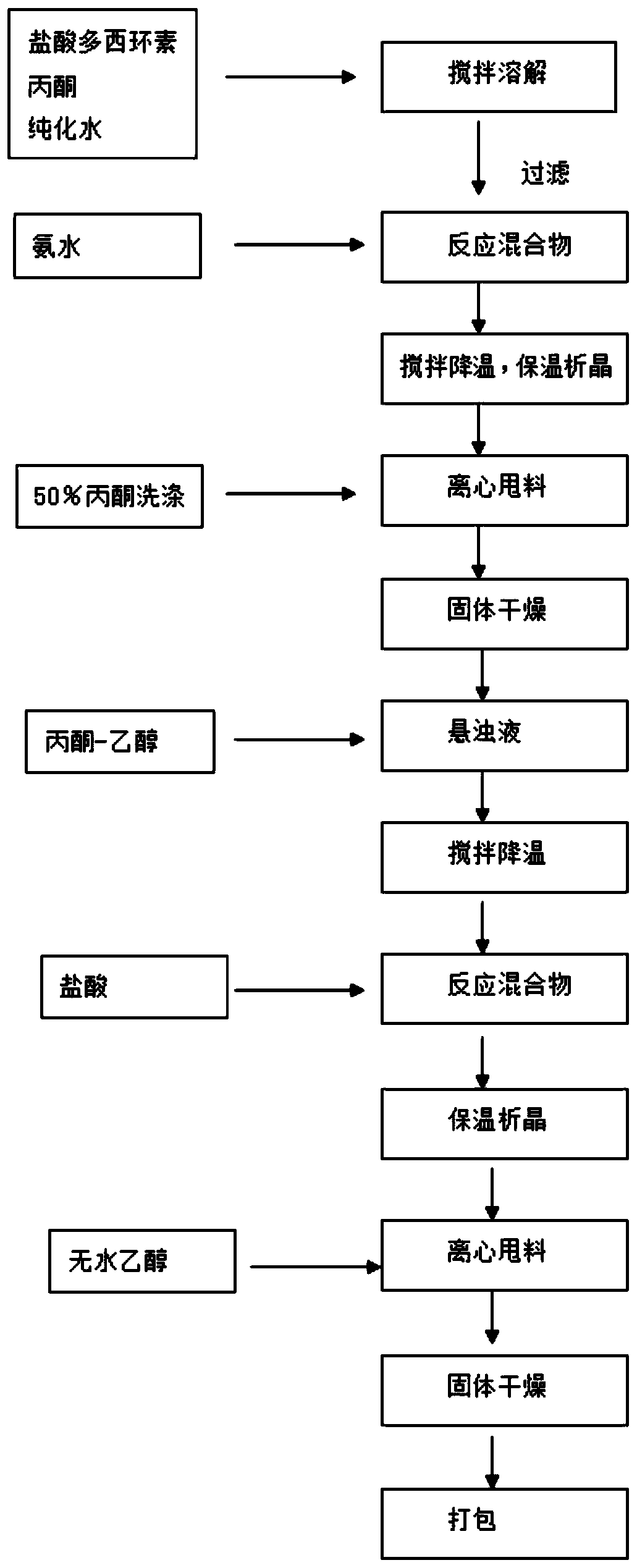

[0035] A method for refining doxycycline hydrochloride, comprising the steps of:

[0036] Step S1, adding 400 g of raw material doxycycline hydrochloride into a mixed solvent of water and acetone until dissolved, then filtering under reduced pressure to obtain the first filtrate and the first filter residue, washing the first filter residue with a mixed solvent of water and acetone and filtering to obtain the second Two filtrates, the second filtrate is combined with the first filtrate to obtain filtrate; wherein the volume ratio of water and acetone in the mixed solvent of water and acetone is 1:1, wherein the volume mass of the mixed solvent of water and acetone and raw material doxycycline hydrochloride The ratio is 8:1;

[0037] Step S2, control the temperature to 25°C, add concentrated ammonia water to the filtrate obtained in step S1 to adjust the pH to 6.0, stir and lower the temperature to 15°C, keep warm and crystallize, and then centrifugally filter to obtain the fir...

Embodiment 2

[0042] A method for refining doxycycline hydrochloride, comprising the steps of:

[0043] Step S1, adding 400 g of raw material doxycycline hydrochloride into a mixed solvent of water and acetone until dissolved, then filtering under reduced pressure to obtain the first filtrate and the first filter residue, washing the first filter residue with a mixed solvent of water and acetone and filtering to obtain the second Two filtrates, the second filtrate is combined with the first filtrate to obtain filtrate; wherein the volume ratio of water and acetone in the mixed solvent of water and acetone is 2:1, wherein the volume mass of the mixed solvent of water and acetone and raw material doxycycline hydrochloride The ratio is 7:1;

[0044] Step S2, control the temperature at 28°C, add concentrated ammonia water to the filtrate obtained in step S1 to adjust the pH to 6.5, stir and cool down to 18°C, keep warm and crystallize, and then centrifugally filter to obtain the first solid cry...

Embodiment 3

[0049] A method for refining doxycycline hydrochloride, comprising the steps of:

[0050] Step S1, adding 400 g of raw material doxycycline hydrochloride into a mixed solvent of water and acetone until dissolved, then filtering under reduced pressure to obtain the first filtrate and the first filter residue, washing the first filter residue with a mixed solvent of water and acetone and filtering to obtain the second Two filtrates, the second filtrate is combined with the first filtrate to obtain filtrate; wherein the volume ratio of water and acetone in the mixed solvent of water and acetone is 1:2, wherein the volume mass of the mixed solvent of water and acetone and raw material doxycycline hydrochloride The ratio is 9:1;

[0051] Step S2, control the temperature at 23°C, add concentrated ammonia water to the filtrate obtained in step S1 to adjust the pH to 5.5, stir and lower the temperature to 13°C, keep warm and crystallize, and then centrifugally filter to obtain the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com