Edible oil preparation method capable of effectively reducing aflatoxin content

A kind of aflatoxin and edible oil technology, applied in the direction of fat oil/fat refining, fat oil/fat production, fat production, etc., can solve the problem of reduction, achieve the effect of increasing specific surface area, improving photocatalytic efficiency, and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

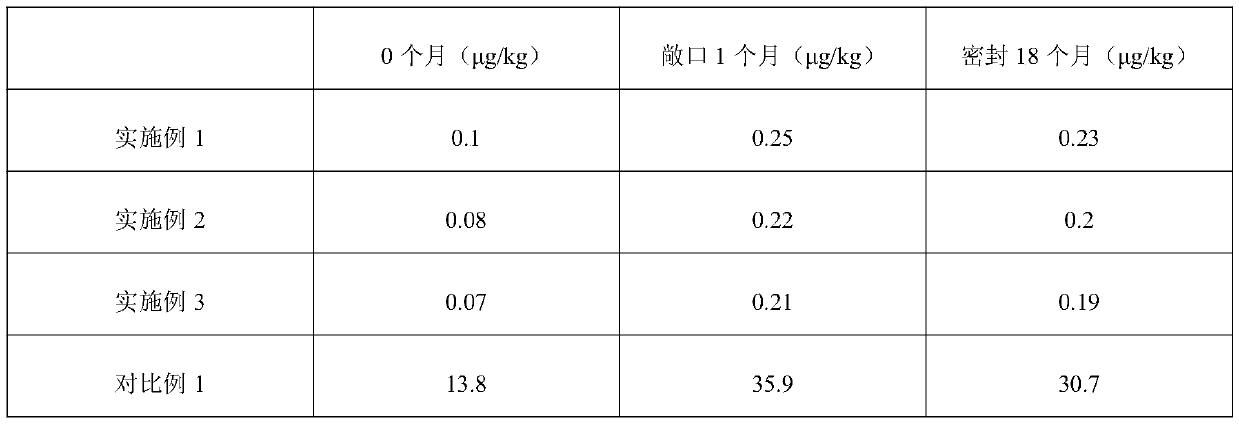

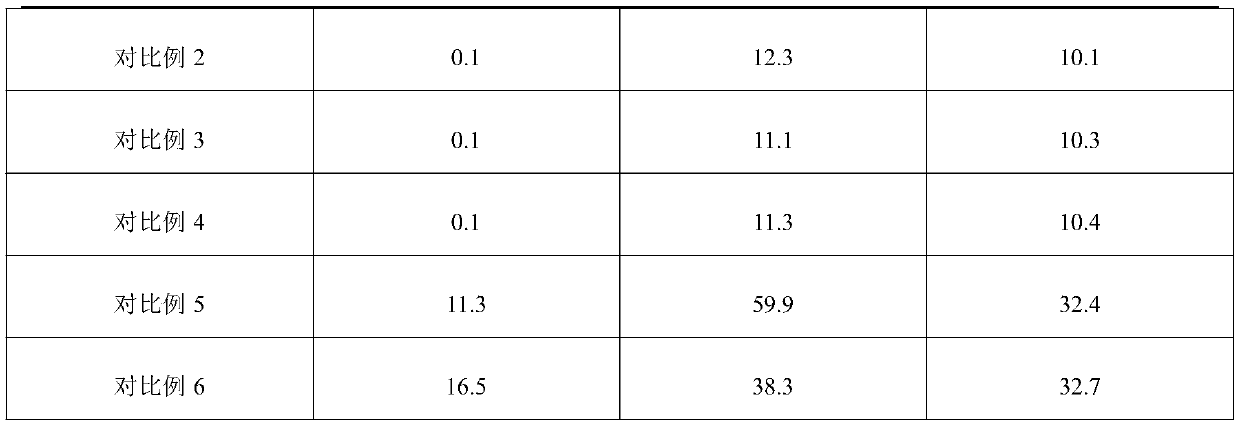

Examples

Embodiment 1

[0041] A kind of edible oil preparation method that effectively reduces aflatoxin content, concrete steps are as follows:

[0042] (1) Preparation of treatment agent: first add nickel nitrate hexahydrate, yttrium nitrate hexahydrate and gadolinium nitrate hexahydrate into N,N'-dimethylformamide, ultrasonically oscillate evenly, then add polyacrylonitrile and stir to make Spinning solution, electrospinning, drying, and calcining to obtain the treatment agent for subsequent use;

[0043] (2) Preparation of additives: dissolving chitosan in 0.2mol / L acetic acid solution, then adding lecithin, ultrasonically oscillating evenly, and dividing into two parts on average, one of which adds perillaldehyde and linoleum oil, and the other Add Bacillus subtilis CMCC63501 in one part, emulsify respectively, combine, freeze-dry in vacuum to obtain the additive, and set aside;

[0044] (3) Then the oily plant material is squeezed to obtain crude oil, then add the treatment agent obtained in ...

Embodiment 2

[0064] A kind of edible oil preparation method that effectively reduces aflatoxin content, concrete steps are as follows:

[0065] (1) Preparation of treatment agent: first add nickel nitrate hexahydrate, yttrium nitrate hexahydrate and gadolinium nitrate hexahydrate into N,N'-dimethylformamide, ultrasonically oscillate evenly, then add polyacrylonitrile and stir to make Spinning solution, electrospinning, drying, and calcining to obtain the treatment agent for subsequent use;

[0066] (2) Preparation of additives: dissolving chitosan in 0.3mol / L acetic acid solution, then adding lecithin, ultrasonically oscillating evenly, and dividing into two parts on average, one of which adds perillaldehyde and linoleum oil, and the other Add Bacillus subtilis CMCC63501 in one part, emulsify respectively, combine, freeze-dry in vacuum to obtain the additive, and set aside;

[0067] (3) Then the oily plant raw material is squeezed to obtain crude oil, and then the treatment agent obtained...

Embodiment 3

[0087] A kind of edible oil preparation method that effectively reduces aflatoxin content, concrete steps are as follows:

[0088] (1) Preparation of treatment agent: first add nickel nitrate hexahydrate, yttrium nitrate hexahydrate and gadolinium nitrate hexahydrate into N,N'-dimethylformamide, ultrasonically oscillate evenly, then add polyacrylonitrile and stir to make Spinning solution, electrospinning, drying, and calcining to obtain the treatment agent for subsequent use;

[0089] (2) Preparation of additives: dissolving chitosan in 0.25mol / L acetic acid solution, then adding lecithin, ultrasonically oscillating evenly, and dividing into two parts on average, one of which adds perillaldehyde and linoleum oil, and the other Add Bacillus subtilis CMCC63501 in one part, emulsify respectively, combine, freeze-dry in vacuum to obtain the additive, and set aside;

[0090] (3) Then the oil-containing plant material is squeezed to obtain crude oil, and then the treatment agent o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com