Method for rapidly determining content of hyaluronic acid in fermentation liquor

A hyaluronic acid and rapid determination technology, applied in the fields of enzymology and medicinal chemistry, can solve the problems of complex operation, influence judgment, and many interference factors, and achieve the effect of large number of samples, high specificity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

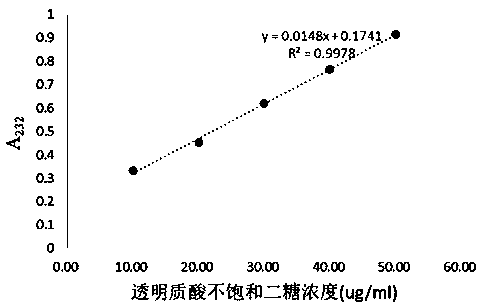

[0044] 1. Preparation of standard curve

[0045] 1. Accurately weigh 0.1 g (WS) of hyaluronic acid unsaturated disaccharide (4,5-unsaturated disaccharide) standard (use phosphorus pentoxide as desiccant and vacuum-dry to constant weight, content> 99.5%), Put it in a 100 ml volumetric flask, add purified water to dissolve and dilute to the mark, shake well, and use it as a stock solution. Accurately measure 5.0 ml of the stock solution before use, put it in a 100 ml measuring bottle, add water to make a solution containing 50 μg of hyaluronic acid unsaturated disaccharide per 1 ml, shake well, and obtain the hyaluronic acid unsaturated disaccharide standard solution.

[0046] 2. Take 0ml, 1ml, 2ml, 3ml, 4ml, and 5 ml of standard solutions in test tubes, respectively, add 5ml, 4ml, 3ml, 2ml, 1ml, and 0 ml of purified water, mix well, and adjust to zero with purified water. Determination of UV absorbance value A at 232 nm 232 .

[0047] 3. Take the hyaluronic acid unsaturated...

Embodiment 2

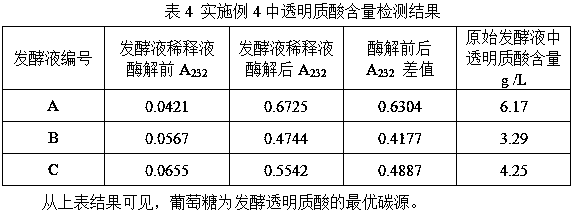

[0058] Take 100 ml of hyaluronic acid fermentation broth in 3 parallel batches, add 10 g of activated carbon respectively, stir for 50 min, centrifuge to get the supernatant, and use enzymatic hydrolysis buffer (80 mM / L Na 2 HPO 4 -NaH 2 PO 4 Buffer, pH6.0) Dilute each fermentation broth 40 times to prepare the solution to be tested; take 1 ml of the solution to be tested, add 150 IU of hyaluronidase, and dilute the enzymatic hydrolysis buffer to 10 ml, at a temperature of 25 Complete enzymatic hydrolysis at ℃ for 25 minutes, and boil at 100℃ for 2 minutes. Measure the ultraviolet absorption value of the enzymolysis solution at 232nm to obtain the A 232 .

[0059] Except for replacing the hyaluronidase with an equal volume of purified water, the fermentation broth was processed synchronously according to the same steps above to obtain the A before enzymolysis of the fermentation broth dilution. 232 .

[0060] A before and after enzymolysis according to the fermentation...

Embodiment 3

[0063] Take 100 ml of the hyaluronic acid fermentation broth fermented for 16 h, 20 h, 24 h, 28 h, 32 h, 36 h, 40 h, and 44 h, and add LX-60 adsorption resin from Xi’an Lanxiao Technology Co., Ltd. 20 g, shake for 1 h, and centrifuge to get the supernatant. Enzyme digestion buffer (50 mM / L Na 2 HPO 4 -NaH 2 PO 4buffer, pH6.0) to dilute each fermentation broth 20 times to prepare the solution to be tested; take 1 ml of the solution to be tested, add 900 IU of hyaluronidase, and dilute the enzymatic hydrolysis buffer to 10 ml, at a temperature of 30 Complete enzymatic hydrolysis at ℃ for 20 minutes, and boil at 100℃ for 2 minutes. Measure the ultraviolet absorbance value of the enzymolysis solution at 232 nm to obtain the A 232 .

[0064] Except for replacing the hyaluronidase with an equal volume of purified water, the fermentation broth was processed synchronously according to the same steps above to obtain the A before enzymolysis of the fermentation broth dilution. 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com