Mink oil betaine surfactant and preparation method thereof

A technology of surfactant and mink oil, applied in the field of mink oil betaine surfactant and preparation thereof, can solve problems such as the performance of mink oil not being fully exerted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

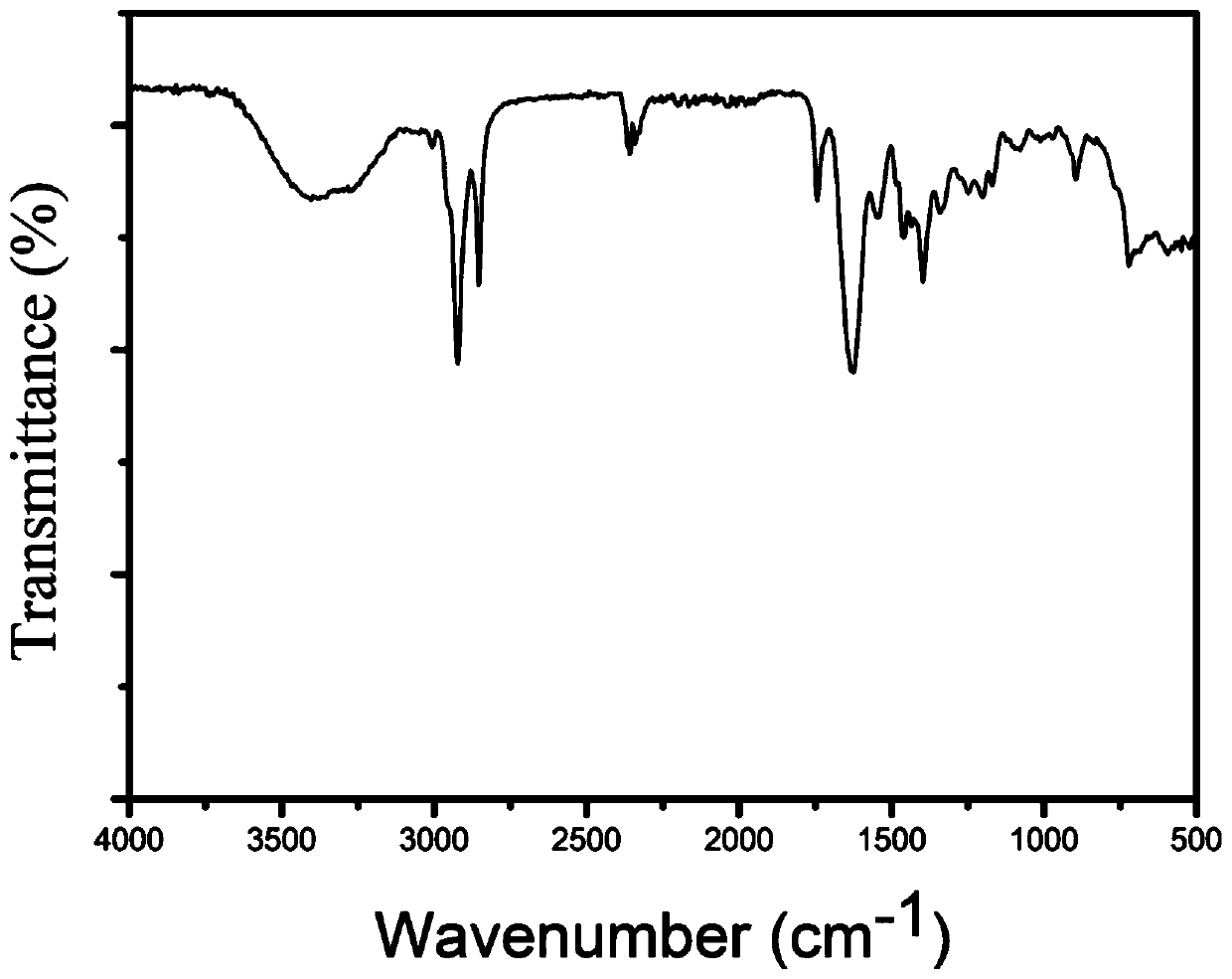

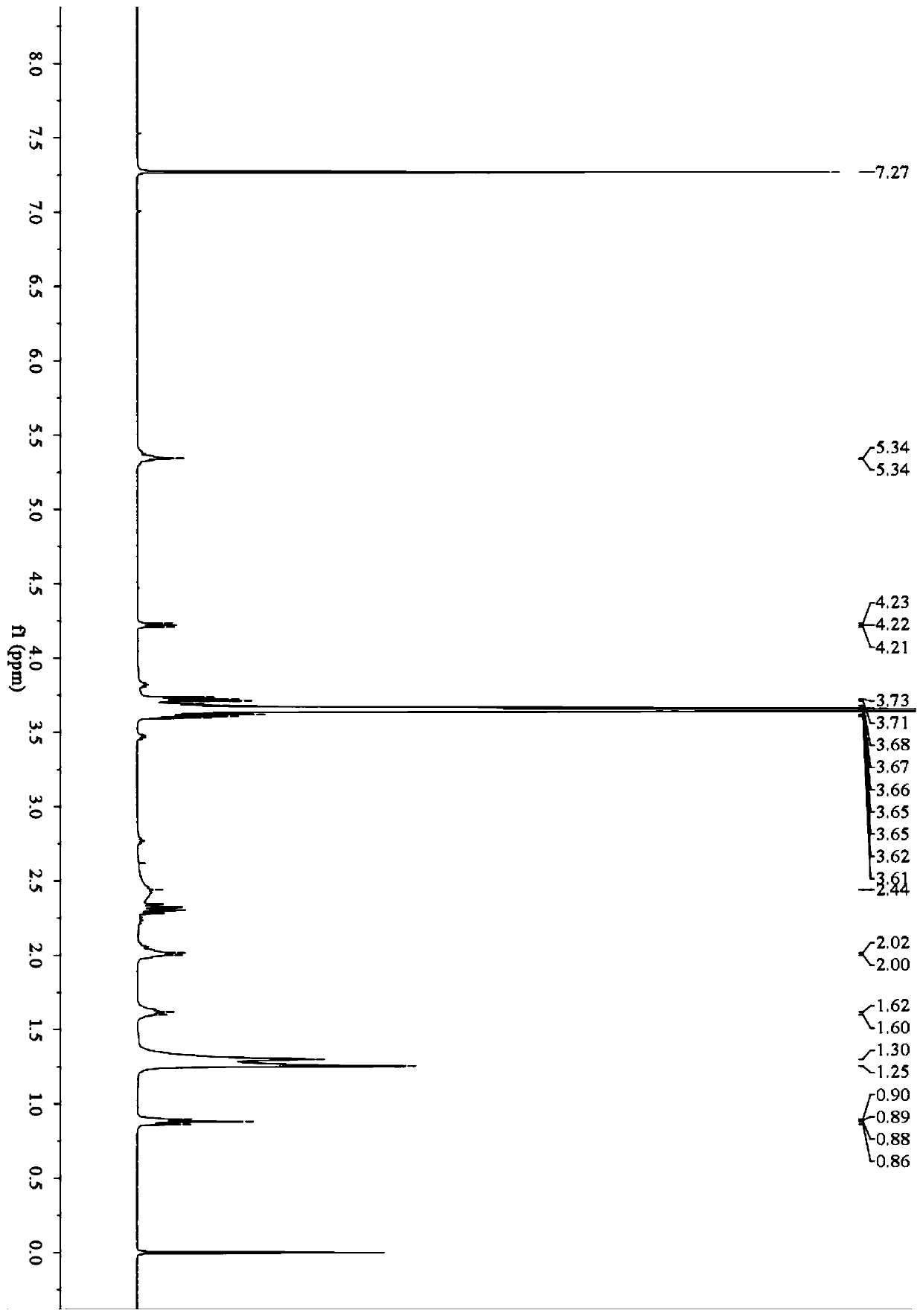

Image

Examples

Embodiment 1

[0051] A preparation method of mink oil amidopropyl betaine surfactant comprises the following steps:

[0052] (1) Amidation reaction: Add mink oil (100.0g), 3-dimethylaminopropylamine (105.0g) and pyridine (10.0g) into a round bottom flask, and react at 160°C for 5h; after the reaction, depressurize Impurities such as by-products, pyridine and unreacted 3-dimethylaminopropylamine were removed by distillation, and then 5% Na 2 CO 3 solution, brine, and water to wash out unreacted components, and dry to obtain mink oil amidopropyl dimethyl tertiary amine;

[0053] (2) Quaternization reaction: Mink oil amidopropyl dimethyl tertiary amine (50g), sodium chloroacetate (20g), isopropanol / water (1.5: 1, 50mL), stirred at room temperature until the sodium chloroacetate was completely dissolved, then adjusted the pH value at 7-8 with 10% NaOH solution, and reacted at 80°C for 6h; after the reaction, the isopropanol and water were removed by rotary evaporation, and then added 2 times...

Embodiment 2

[0058] A preparation method of mink oil amidopropyl betaine surfactant comprises the following steps:

[0059] (1) Amidation reaction: Add mink oil (80.0g), 3-dimethylaminopropylamine (96.0g), toluene (100mL) and KOH (10.0g) in a round bottom flask, and react at 80°C for 10h; After the end, impurities such as by-products, toluene and unreacted 3-dimethylaminopropylamine were removed by distillation under reduced pressure; 2 CO 3 solution, brine, and water to wash out unreacted components, and dry to obtain mink oil amidopropyl dimethyl tertiary amine;

[0060] (2) Quaternization reaction: Mink oil amidopropyl dimethyl tertiary amine (50g), sodium chloroacetate (30g), isopropanol / water (2.0: 1, 80mL), stirred at room temperature until the sodium chloroacetate was completely dissolved, then adjusted the pH value to 7-8 with 20% NaOH solution, and reacted at 50°C for 10h; 2.5 times the volume of isopropanol, stirred and filtered to remove unreacted sodium chloroacetate and oth...

Embodiment 3

[0062]A preparation method of mink oil amidopropyl betaine surfactant comprises the following steps:

[0063] (1) Amidation reaction: Add mink oil (100.0g), 3-dimethylaminopropylamine (110.0g), triethylamine (20mL) and NaOH (5.0g) into a round bottom flask, and react at 100°C for 8h After the reaction finishes, impurities such as by-product, triethylamine and unreacted 3-dimethylaminopropylamine are removed by distillation under reduced pressure; Then use 5% Na 2 CO 3 solution, brine, and water to wash out unreacted components, and dry to obtain mink oil amidopropyl dimethyl tertiary amine;

[0064] (2) Quaternization reaction: Mink oil amidopropyl dimethyl tertiary amine (50g), sodium chloroacetate (25g), isopropanol / water (2.0: 1, 60mL), stirred at room temperature until the sodium chloroacetate was completely dissolved, then adjusted the pH value to 7-8 with 15% NaOH solution, and reacted at 100°C for 4 hours; after the reaction, the isopropanol and water were removed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com